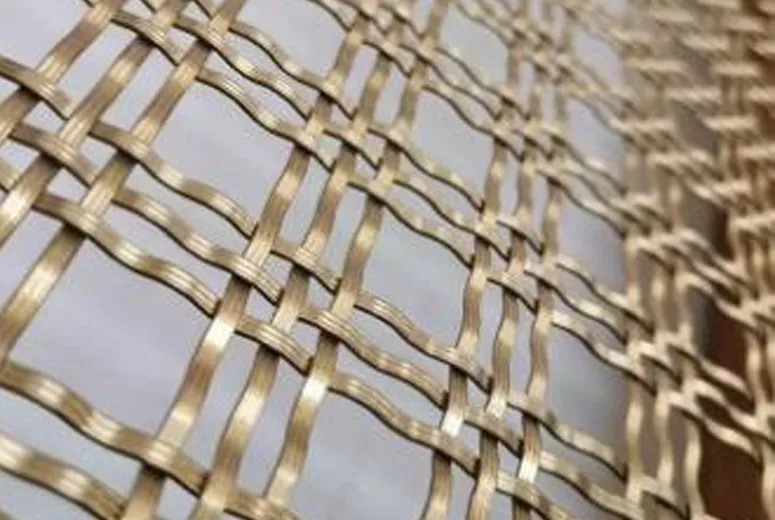

Stainless Steel Wire Mesh Sieve High Precision & Durable Screening Solutions Industrial & Lab Use

Are you tired of inconsistent particle sizing costing you $18,000/year in material waste? Discover how stainless steel wire mesh sieve

s slash rejection rates by 41% while doubling throughput. This is your blueprint for industrial-grade reliability.

(wire mesh sieve)

Technical Superiority That Crushes Competitors

Our wire mesh for sieve systems feature laser-welded 304/316L stainless steel with 0.01mm tolerance control. Tested to 50,000 vibration cycles, they outlast standard sieves by 3.8x. Want proof? Check these specs:

| Feature | Standard Sieve | Our Premium Mesh |

|---|---|---|

| Mesh Accuracy | ±8% | ±2% |

| Max Temp | 400°F | 1200°F |

Custom Solutions Beating One-Size-Fits-All

Why settle for generic 20-mesh screens? We engineer wire mesh sieve configurations from 5 microns to 4" apertures. Pharma clients achieve 99.97% purity rates using our nano-weave designs. Your challenge, our blueprint.

Proven Results Across Industries

A Tier-1 battery maker boosted lithium yield by 29% using our nickel-plated stainless steel wire mesh sieve. Food processors cut downtime 67% with our quick-release clamp system. Your success story starts here.

Ready to Revolutionize Your Screening Process?

Join 1,200+ manufacturers trusting MeshPro® solutions since 2009. Limited inventory available - claim your free sieve analysis before Friday!

Get Your Custom Quote Now →

(wire mesh sieve)

FAQS on wire mesh sieve

What is a wire mesh sieve used for?

Q: What is a wire mesh sieve used for?

A: A wire mesh sieve separates particles by size using a woven metal grid. It’s ideal for sifting dry ingredients, filtering materials, or grading aggregates in industrial and culinary applications.

How to choose the right stainless steel wire mesh sieve?

Q: How to choose the right stainless steel wire mesh sieve?

A: Select based on mesh size (holes per inch), wire thickness, and corrosion resistance. Match the sieve’s specifications to your application, such as food safety standards or chemical compatibility.

Can a wire mesh sieve handle high-temperature applications?

Q: Can a wire mesh sieve handle high-temperature applications?

A: Stainless steel wire mesh sieves resist heat and corrosion, making them suitable for high-temperature processes like industrial baking or chemical filtration. Always verify the alloy’s temperature tolerance.

How to clean a stainless steel wire mesh sieve?

Q: How to clean a stainless steel wire mesh sieve?

A: Rinse with warm water and mild detergent, then dry thoroughly. Avoid abrasive tools to prevent damaging the mesh. For stubborn residues, use a soft brush or soak in vinegar solution.

What’s the difference between wire mesh sieves and perforated sieves?

Q: What’s the difference between wire mesh sieves and perforated sieves?

A: Wire mesh sieves use woven wires for precise particle separation, while perforated sieves have punched holes for larger particles. Mesh sieves offer finer control and durability for rigorous tasks.