Applications and Benefits of Deep-Processed Wire Mesh Products

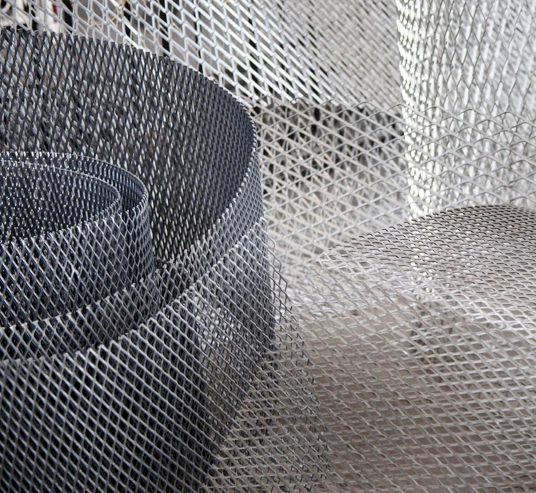

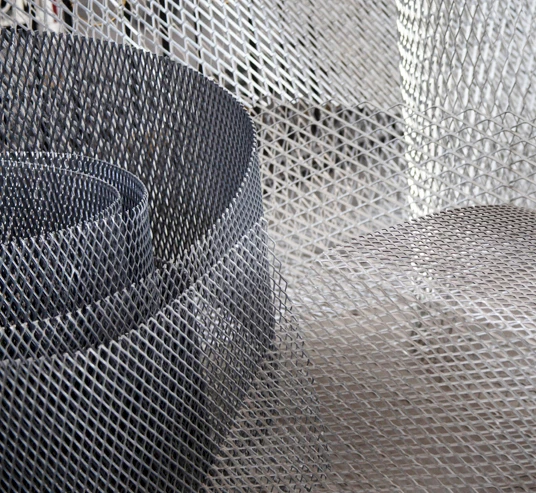

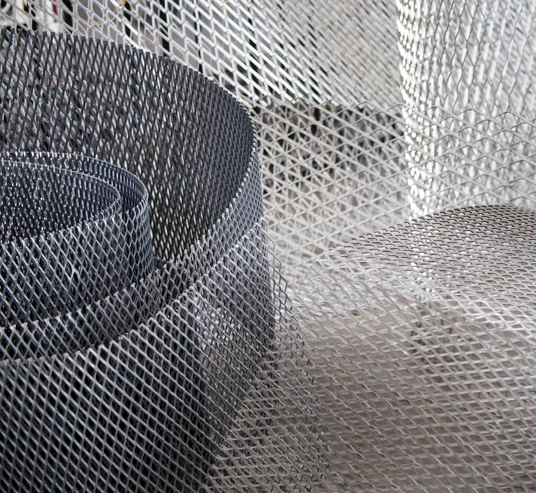

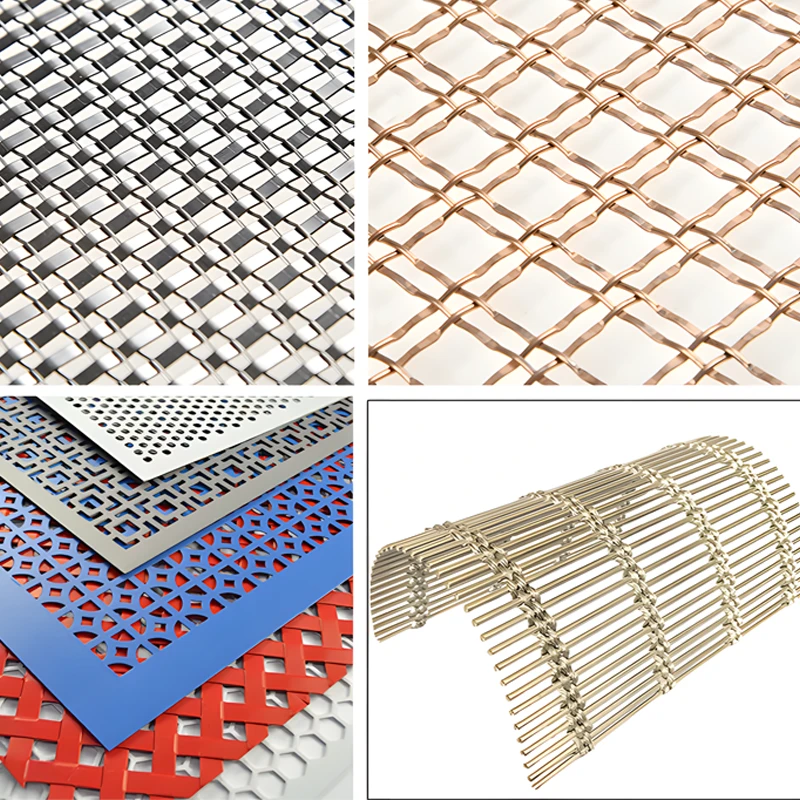

Deep-processed wire mesh products refer to various advanced applications of wire mesh through cutting, welding, bending, coating, and other processes. These products are widely used in industries such as construction, agriculture, mining, transportation, and security due to their durability, strength, and versatility.One of the most common deep-processed wire mesh products is welded wire mesh panels, which are extensively used for fencing, reinforcement, and protective barriers. These panels are made by welding intersecting wires, ensuring strong structural integrity. Additionally, expanded metal mesh is created by stretching and cutting metal sheets, providing excellent ventilation and strength while maintaining lightweight properties.

Another popular category includes perforated metal sheets, which feature various hole patterns for filtration, soundproofing, and decorative purposes. Similarly, wire mesh filters are essential in industries such as petroleum, chemical processing, and food manufacturing, where precise filtration is required.Furthermore, deep processing techniques allow for the production of decorative wire mesh, which is often used in architectural designs, interior decorations, and furniture. Barbed wire and razor wire are also key products, serving security and military applications by providing effective barriers against intrusions.Coatings such as galvanization, PVC, or powder coating enhance the durability and corrosion resistance of wire mesh products, making them suitable for outdoor and harsh environments.Deep-processed wire mesh products offer a diverse range of applications, from industrial and commercial use to security and aesthetic enhancements. Their durability, adaptability, and cost-effectiveness make them indispensable in modern industries.