-

5 Selling Points

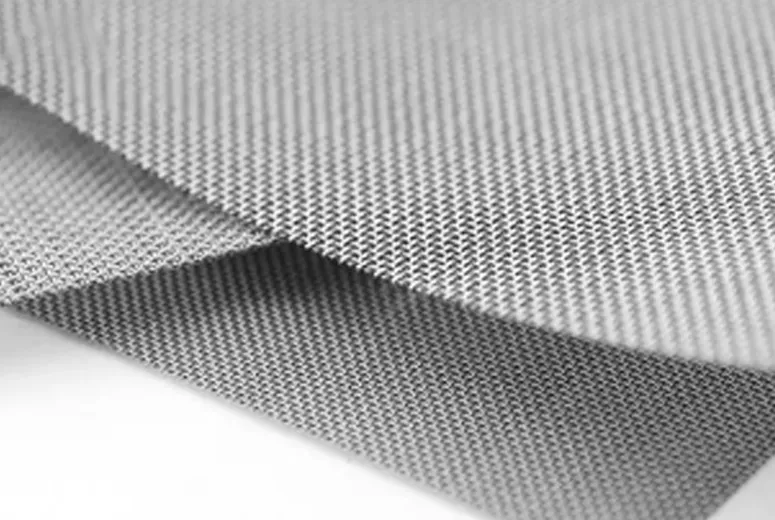

Metal filter mesh discs is a widely used filter element in industrial and commercial fields. Its main function is to ensure that impurities and particles are effectively removed when the fluid or gas is filtered. Our metal filter mesh discs is made of a variety of high-performance materials to ensure its durability and reliability. Some common materials include stainless steel, aluminum alloy, copper alloy and carbon steel, which allows our filter mesh to adapt to different environments and usage requirements, thereby meeting the multiple needs of customers.

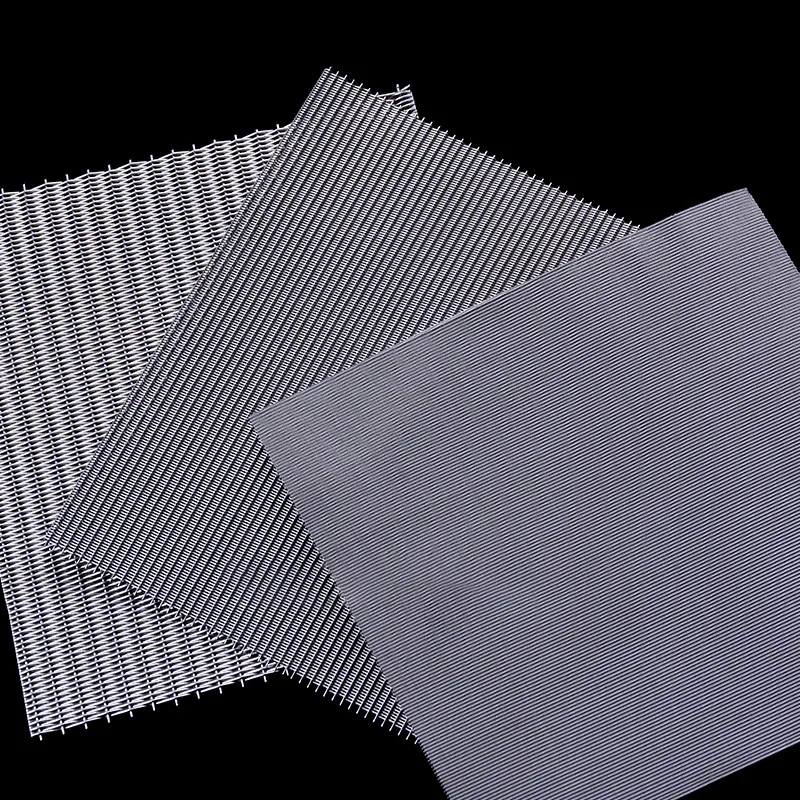

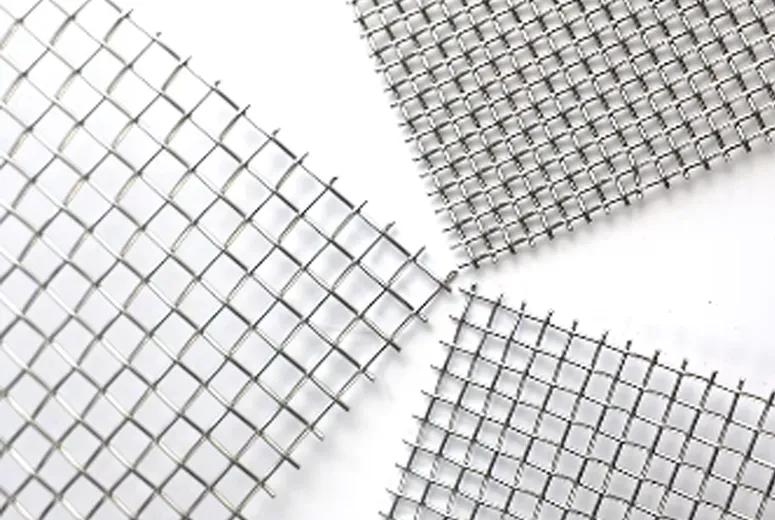

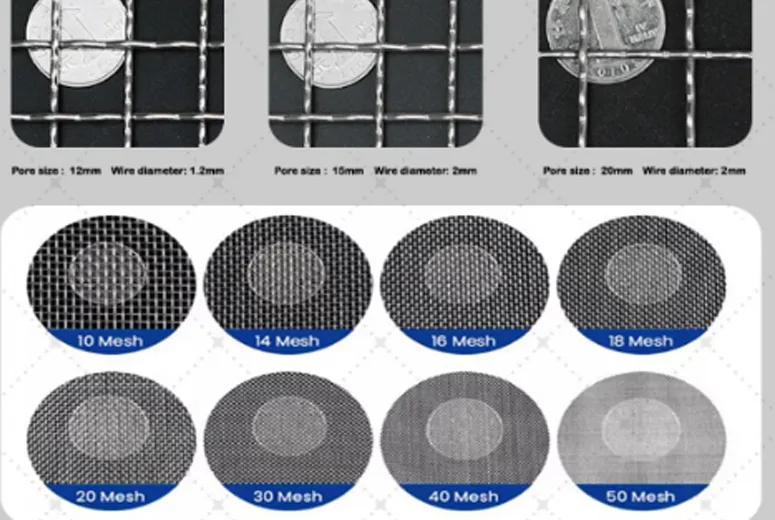

In terms of filtration performance, our metal filter mesh discs has a variety of mesh sizes to choose from, which can be customized according to specific application requirements. Our mesh sizes range from very fine microns to coarse millimeters to meet the filtration accuracy requirements of various fluids and gases. Whether you need to prevent the intervention of very small particles or want to retain some larger particles, our products can achieve accurate filtration and ensure the purity of the fluid.

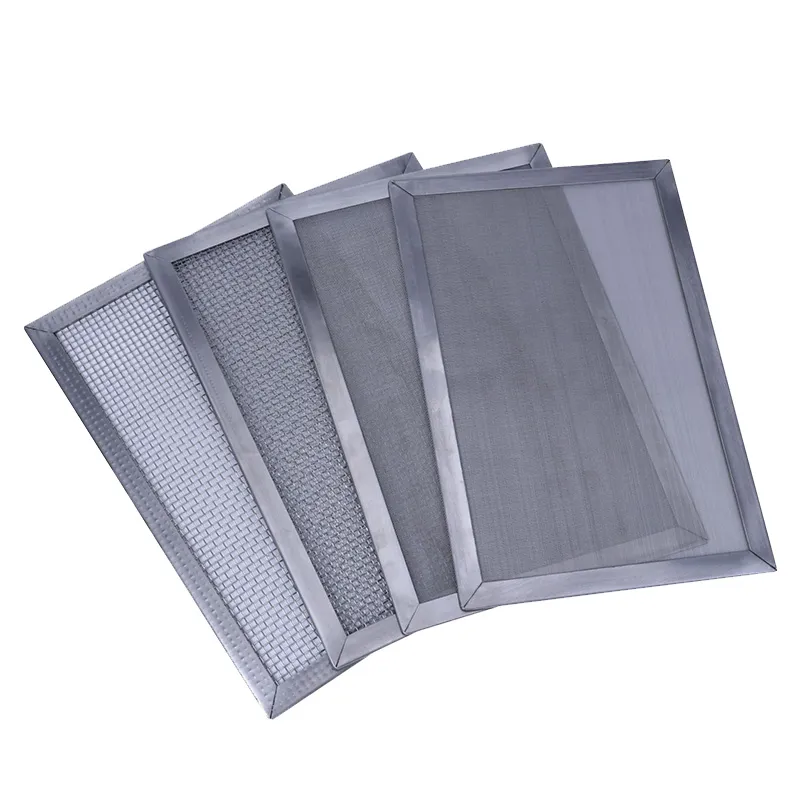

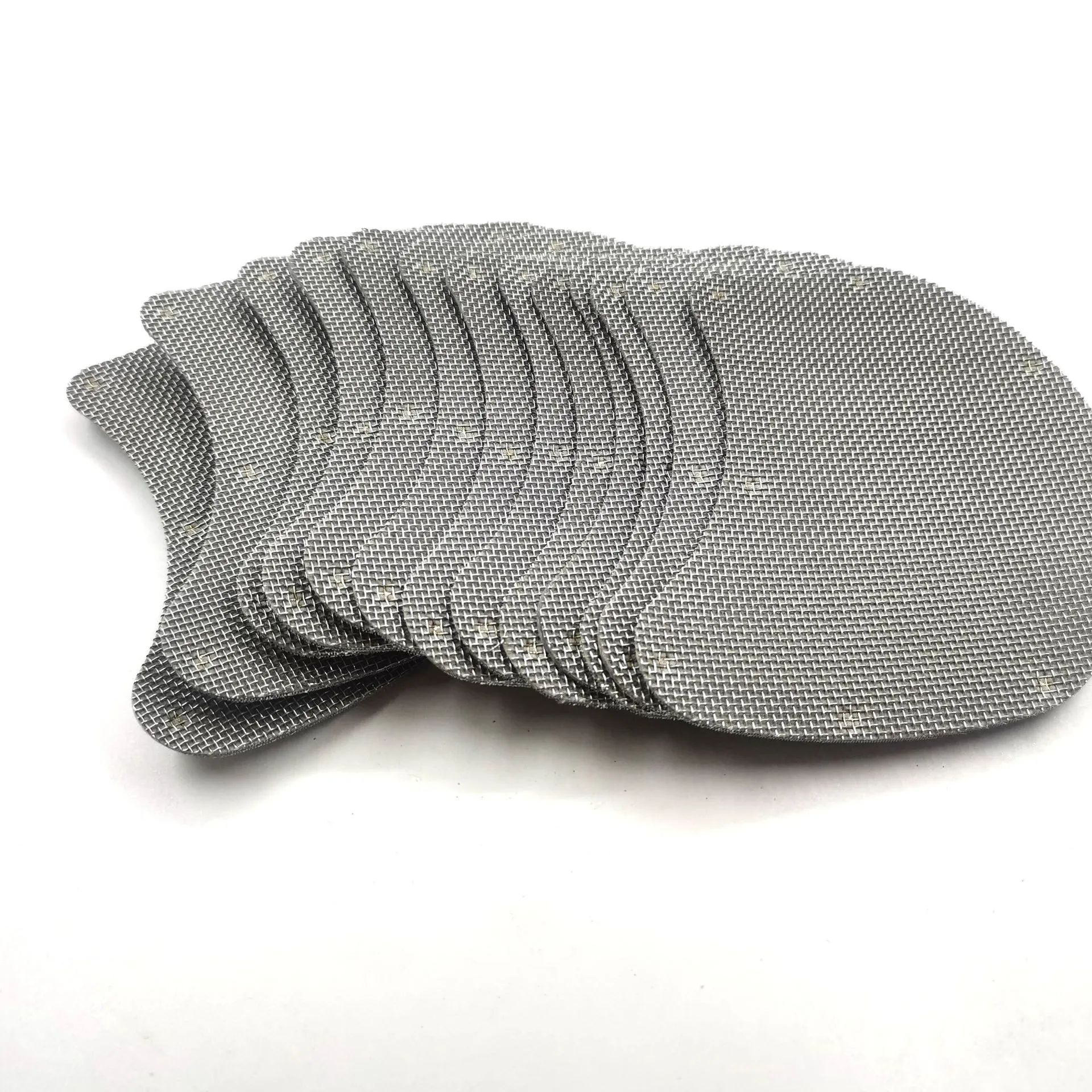

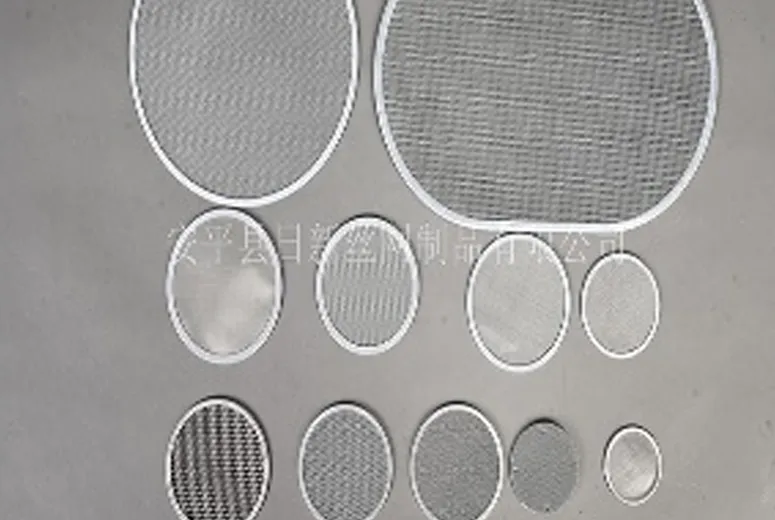

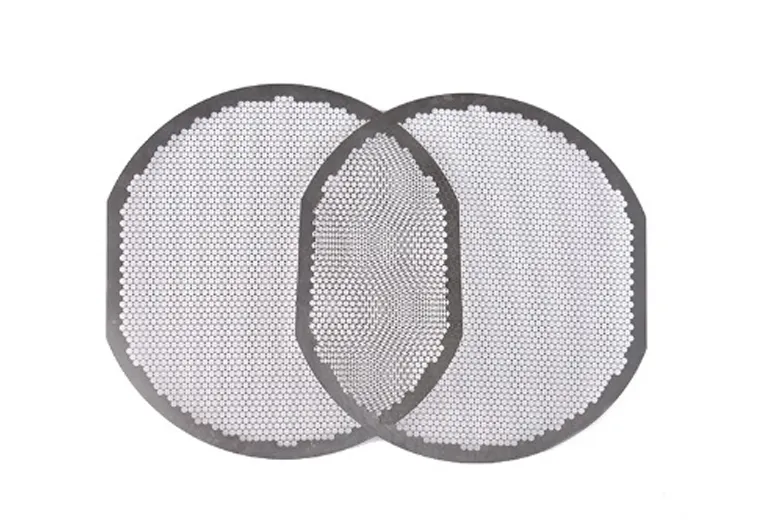

Our metal filter mesh discs can provide a variety of shapes, mainly divided into round, square, rectangular, oval and special shapes. In order to adapt to different equipment and pipelines, our filter mesh discs design can flexibly adapt to a variety of structures and geometries. This variety of shape selection makes it more convenient to install and use. You can choose the most suitable shape of filter mesh discs according to your needs to achieve the best filtration effect.

We adhere to the principle of quality first in the production process and provide base mesh discs and edge mesh discs with stronger edges. The base mesh discs part has good permeability and filtration capacity, while the edge mesh discs is specially designed to have higher load-bearing capacity and stability. This dual design ensures that our metal filter mesh discs still performs well under high pressure and high flow conditions, and is not easy to deform, break or fail, thereby improving the safety of use and long life.

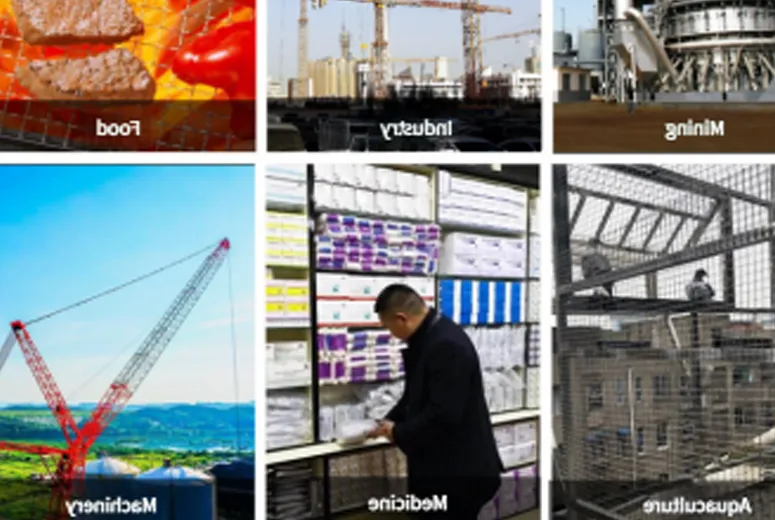

Metal filter mesh discs has a wide range of applications, covering chemical, pharmaceutical, food, metallurgy, environmental protection and other industries. Whether in liquid filtration, gas separation, solid recovery or in the protection of mechanical equipment, metal filter mesh discs is an indispensable and important part. We are always committed to providing the best filtration solutions to help customers improve production efficiency and reduce operating costs.

In short, choosing our metal filter mesh discs will give you a variety of materials and mesh options, excellent filtration accuracy, flexible shape design, excellent product quality and a wide range of applications. These five selling points can not only effectively meet your various needs, but also bring significant improvement and growth to your business. We look forward to working with you to create a cleaner and more efficient future.

-

-

Product Parameter Characteristics

Product name

Metal filter Mesh discs

Place of production

China Hebei

Type

Customized product

Texture of wood

Stainless steel, aluminum alloy, copper alloy and carbon steel, etc.

Craft

Weaving, punching, etching and laser cutting processes

Colour

metal color

Size

Customized

Style

Simplicity

Application scenario

Kitchen, agriculture, laboratory, chemical industry, etc.

-

Popular Science Product Knowledge

One Paragraph:what is this product?

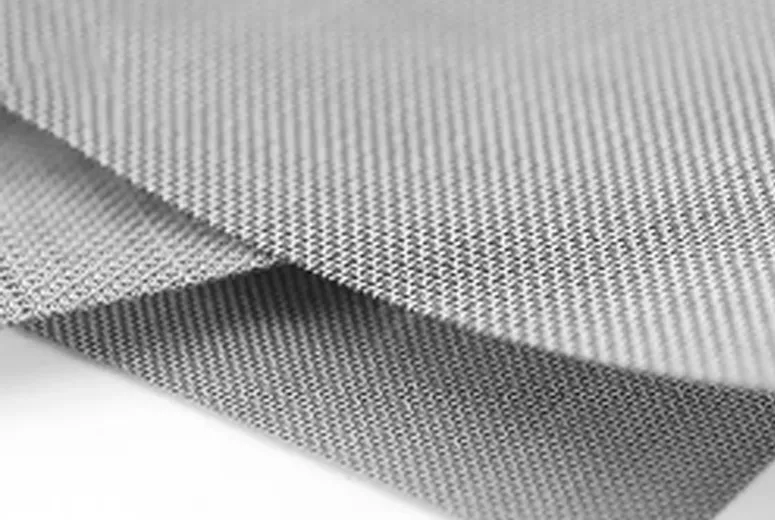

Metal filter mesh discs is a filter element made of metal wire. It is made of metal materials such as stainless steel and copper, and is woven or welded. Its mesh specifications are diverse and can accurately control the filtering accuracy. This mesh not only has good wear and corrosion resistance, but also has high strength and can withstand a certain amount of pressure. In industrial production, it is often used for filtering liquids and gases, such as separating impurities in petrochemicals and filtering the intake air of automobile engines. It can effectively ensure the stable operation of equipment and improve product quality.

Two Paragraph:This product application?Metal filter mesh discs is widely used. In the field of petrochemicals, it can filter crude oil, chemical raw materials, etc., separate impurities, and ensure smooth production processes. In the food and beverage industry, it can filter juice, alcohol, etc. to ensure that the drinks are pure and free of impurities. In the pharmaceutical industry, it is used to filter liquid medicine to ensure the quality and safety of medicines. In automobile manufacturing, it is used as a filter for engine intake and fuel to improve engine performance. In addition, in air purification equipment, it can filter dust and particulate matter in the air, improve air quality, and provide reliable protection for production and life in many fields.

-

Pictures Of Products And Applications

Screen Technology:

-

Weaving process

-

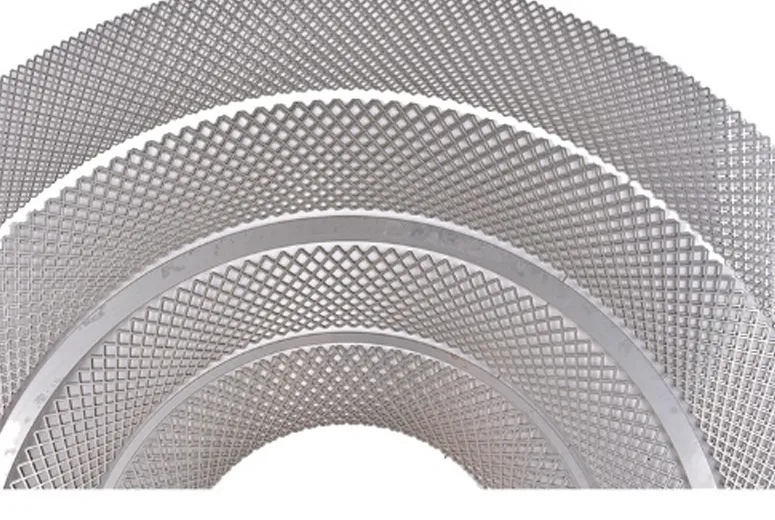

Punching process

Product Details

-

Basic mesh discs:simple structure, single-layer structure, low cost and wide application.

-

Multi-layer mesh discs: multi-layer combination, high filtration accuracy, can intercept a variety of impurities.

-

Edge mesh discs:the edge is hemmed, more durable and easy to install.

Sintered mesh discs:through sintering process, high strength, stable and reliable filtration performance.

Special-shaped mesh discs:customized according to special needs, suitable for complex and unique application scenarios.

Application Scenarios

Scope of application:

Widely used in petrochemical, pharmaceutical, food and beverage, machinery manufacturing, sewage treatment, etc.

Mainly used for screening and separation of gas, liquid, powder filtration and other media.

-

-

What is the average lead time?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.