Wire Mesh Filters | Steel & Stainless Expanded Metal Solutions

In the vast landscape of industrial and commercial filtration, the wire mesh filter stands as a cornerstone technology, critical for ensuring purity, protecting sensitive equipment, and optimizing process efficiency across countless sectors. From the microscopic precision required in pharmaceuticals to the robust demands of heavy industry, these versatile components play an indispensable role. This comprehensive guide delves deep into the world of wire mesh filters, exploring their intricate design, manufacturing prowess, diverse applications, and the critical factors that define their performance and reliability. We will provide insights into current industry trends, detailed technical specifications, and real-world application scenarios, augmented by data-driven comparisons and a focus on established industry standards, to empower you with the knowledge needed to make informed filtration decisions.

Industry Trends and the Evolving Landscape of Filtration

The global filtration market is experiencing significant growth, driven by stringent environmental regulations, increasing demand for cleaner processes, and technological advancements. The demand for high-performance wire mesh filter solutions is particularly pronounced in industries like petrochemicals, pharmaceuticals, food and beverage, and water treatment, where product purity and equipment longevity are paramount. Innovations in materials, such as advanced grades of stainless steel expanded sheet, and manufacturing techniques are leading to filters with enhanced durability, higher filtration efficiency, and extended service life. Furthermore, the integration of smart monitoring systems and automation in filtration processes is emerging as a key trend, allowing for predictive maintenance and optimized operational parameters.

There's a growing emphasis on sustainable and reusable filtration solutions, reducing waste and operational costs. This has spurred developments in self-cleaning filter designs and materials that can withstand aggressive cleaning cycles without degradation. The market also sees a steady demand for specialized metal components, including those made from steel expanded metal, used in various structural and aesthetic applications like protective screens or even as components within larger filtration systems, highlighting the versatility of expanded metals beyond just filters. Interestingly, aesthetic applications like decorative metal grilles for cabinet doors also utilize similar fabrication techniques and material understanding, showcasing the broad utility of metal processing expertise.

Understanding Wire Mesh Filters: Technical Parameters and Specifications

A wire mesh filter is essentially a device that uses a woven or expanded metal fabric to separate solid particles from a fluid (liquid or gas). The effectiveness of a filter is determined by several key technical parameters:

- Material Composition: Common materials include 304, 316, 316L stainless steel expanded sheet, brass, copper, nickel alloys, and galvanized steel. The choice of material depends on the operating temperature, pressure, chemical compatibility, and corrosive environment. For instance, 316L stainless steel is often preferred in highly corrosive or hygienic environments due to its enhanced resistance to pitting and crevice corrosion.

- Mesh Count (LPI): This refers to the number of openings per linear inch. A higher mesh count indicates smaller openings and finer filtration.

- Micron Rating: This specifies the smallest particle size (in micrometers) that the filter can effectively capture. Absolute micron ratings mean all particles larger than the specified size are captured, while nominal ratings indicate a percentage of particles captured.

- Wire Diameter: The thickness of the individual wires forming the mesh. This affects the strength, flow rate, and open area of the filter.

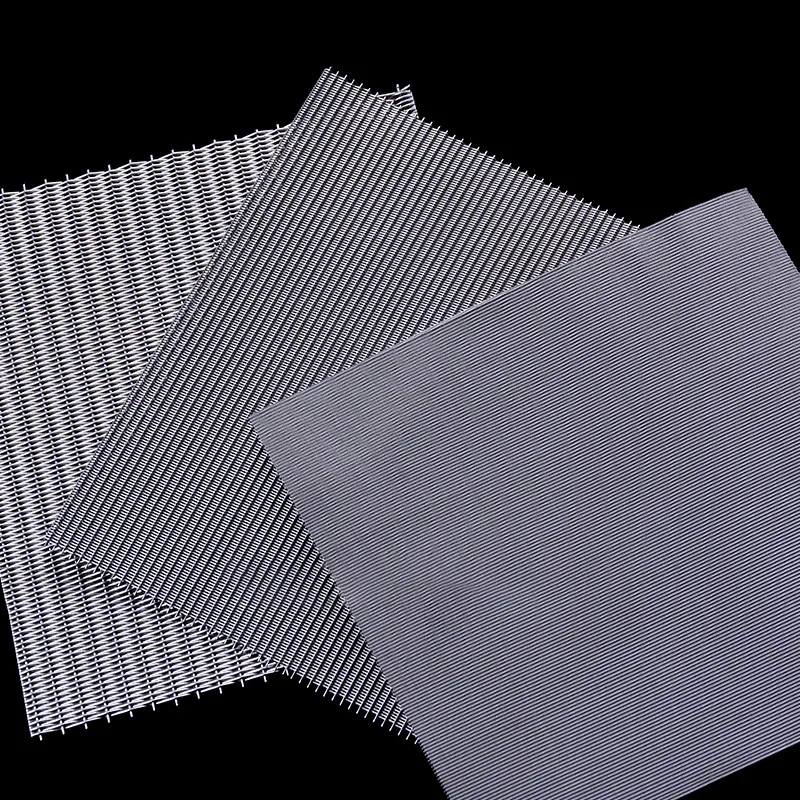

- Weave Pattern: Plain weave, twilled weave, Dutch weave, and reverse Dutch weave are common. Each offers different characteristics regarding strength, open area, and filtration efficiency. Dutch weaves, for example, provide excellent filtration efficiency at very fine micron ratings due to their tightly packed wires.

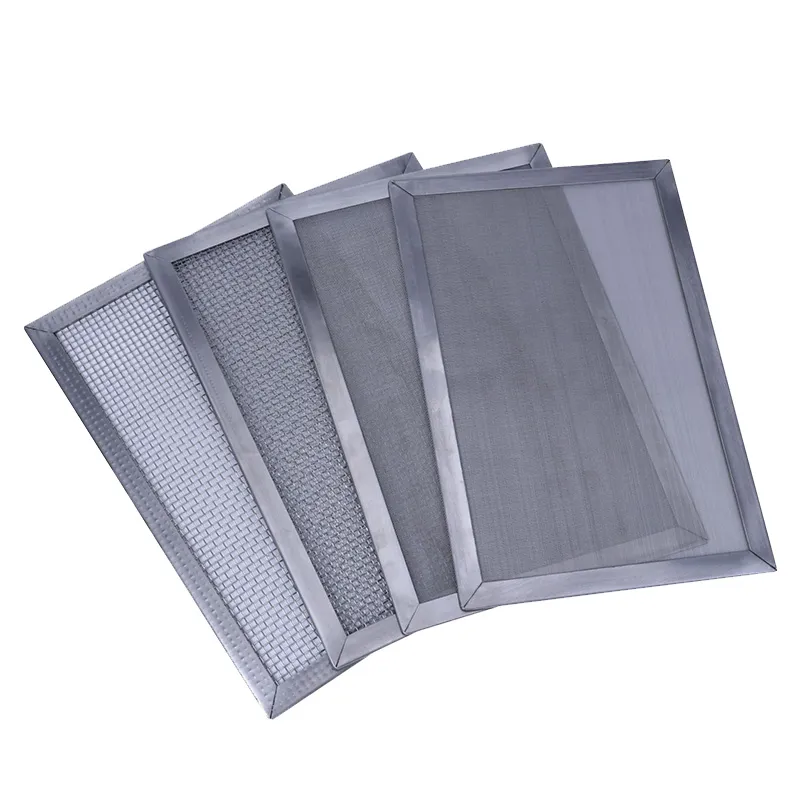

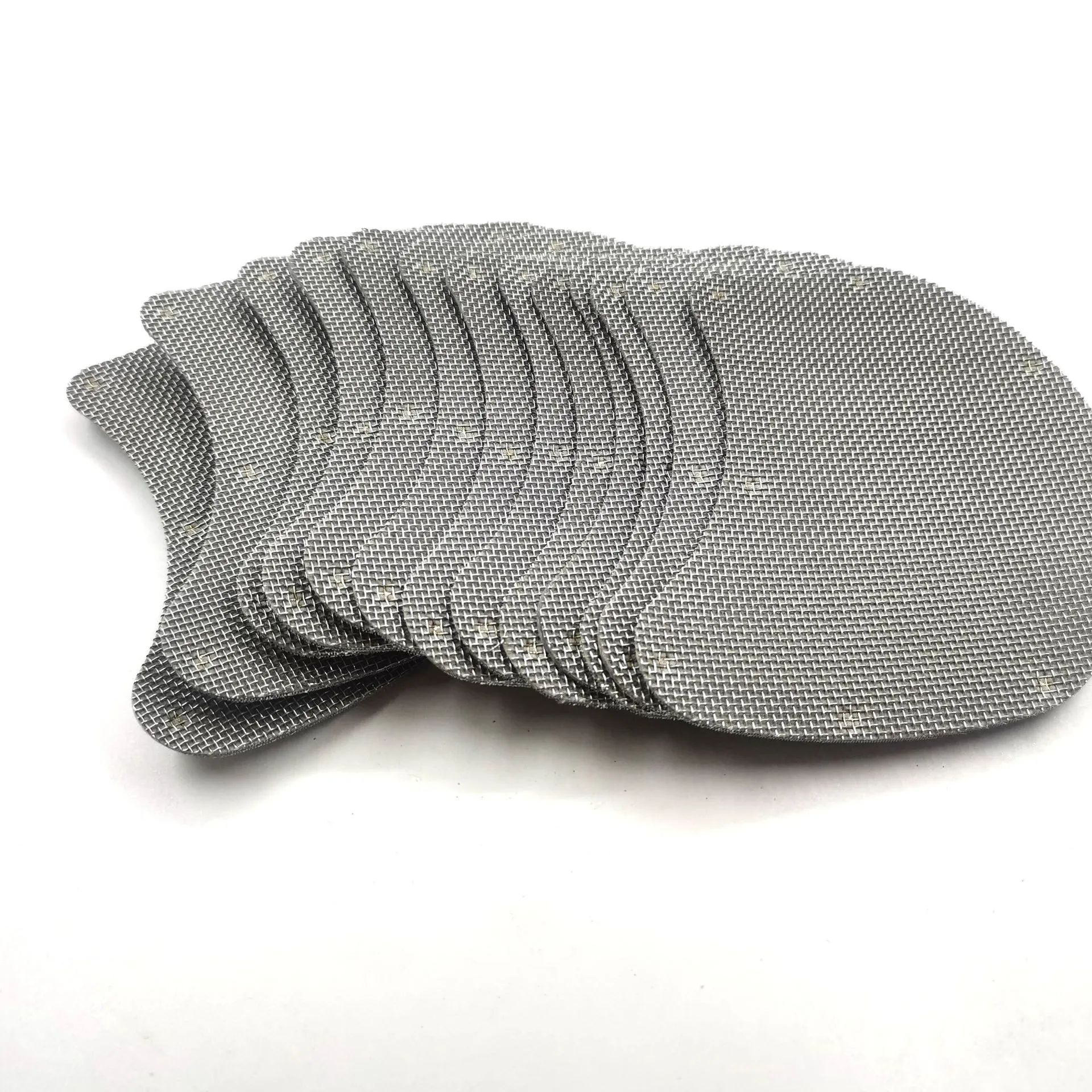

- Filter Shape and Dimensions: Wire mesh filter elements come in various forms, including discs (the focus of our Wire Mesh Filter Disc product), cylinders, cones, baskets, and custom shapes. Dimensions (diameter, height, thickness) are critical for fitting into existing systems.

- Operating Conditions: Filters must be specified considering the maximum operating temperature, pressure differential, and flow rate.

Common Wire Mesh Filter Parameters Table

Below is a table summarizing typical parameters for various wire mesh filter types, often made from materials like stainless steel expanded sheet, showcasing their diverse applications.

| Parameter | Common Range/Type | Typical Application | Notes |

|---|---|---|---|

| Material | SS304, SS316, SS316L, Brass, Monel | General industrial, Food & Bev, Chemical, Marine | Corrosion resistance, temperature tolerance |

| Mesh Count | 2 mesh to 635 mesh (per inch) | Coarse straining to ultra-fine filtration | Higher count = finer filtration |

| Micron Rating (Nominal) | 5 µm to 2000 µm | Protecting pumps, removing particulates, process filtration | Particle size captured |

| Micron Rating (Absolute) | 1 µm to 200 µm | High-purity applications (e.g., pharmaceutical) | Critical for sensitive processes |

| Wire Diameter | 0.02mm to 1.5mm | Strength vs. Open Area | Thicker wire = stronger mesh, less open area |

| Weave Pattern | Plain, Twilled, Dutch, Reverse Dutch | Mechanical strength, filtration efficiency | Dutch weaves offer finer filtration with higher strength |

| Disc Diameter (Wire Mesh Filter Disc) | 10 mm to 600 mm (customizable) | Specific equipment requirements | Our Wire Mesh Filter Disc supports a wide range |

| Operating Temperature | -200°C to 1100°C (material dependent) | Cryogenic to high-temperature processes | Monel/Inconel for extreme temperatures |

| Pressure Rating | Up to 20 MPa (2900 psi) | High-pressure hydraulic systems | Determined by mesh and frame construction |

The Core of Filtration: Wire Mesh Filter Disc Manufacturing Process

The manufacturing of a high-quality Wire Mesh Filter Disc involves a series of precise steps, ensuring consistency, durability, and optimal filtration performance. Our process leverages advanced machinery and skilled craftsmanship to meet stringent industry standards. Here's a detailed breakdown:

Process Flow Explained:

Step 1: Material Selection and Preparation

- Description: The journey begins with the meticulous selection of raw materials, primarily high-grade stainless steel (e.g., SUS304, SUS316, SUS316L), brass, or other specified alloys. These materials arrive in rolls of woven wire mesh or as stainless steel expanded sheet, depending on the filter's design. Quality checks are performed to ensure the material meets chemical composition and mechanical property standards (e.g., ASTM A240 for stainless steel).

- Highlight: Material purity and integrity are paramount, directly impacting the filter's corrosion resistance and longevity.

Step 2: Precision Cutting (Punching/Stamping)

- Description: Utilizing high-precision punching or stamping machines, the selected wire mesh is cut into the desired disc shape and size. For complex designs or specific edge requirements, CNC machining may be employed to achieve exact dimensions and smooth finishes. This step is crucial for maintaining the structural integrity of the mesh and preventing fraying.

- Highlight: Automated cutting ensures uniform disc diameters and clean edges, vital for consistent fit and performance.

Step 3: Multi-Layer Stacking (for composite filters)

- Description: Many high-performance wire mesh filter discs are composed of multiple layers of different mesh counts to achieve specific filtration characteristics (e.g., a coarser support layer, a finer filtration layer, and a protective layer). These layers are carefully stacked in precise alignment. This composite structure enhances filtration efficiency, dirt-holding capacity, and mechanical strength.

- Highlight: Layered construction allows for optimized filtration performance and improved lifespan compared to single-layer designs.

Step 4: Edge Treatment and Binding (Welding/Sintering/Framing)

- Description: To prevent unraveling and provide structural rigidity, the edges of the stacked mesh layers are securely bound. Common methods include:

- Spot Welding/Arc Welding: For metal mesh, individual layers are fused together at points or along the rim.

- Sintering: For very fine meshes or metal fiber felts, a high-temperature process fuses the metallic particles, creating a strong, porous structure. This is particularly relevant for sintered wire mesh filter elements that offer exceptional mechanical strength and backwash capability.

- Crimping/Framing: A metal ring or edge banding is often crimped around the disc, providing a robust frame and facilitating easier installation and removal. This frame can also be made from materials like steel expanded metal for additional support.

- Highlight: Robust edge treatment ensures the filter maintains its shape and integrity under operational pressures, extending its service life.

Step 5: Cleaning and Post-Processing

- Description: After fabrication, filters undergo thorough cleaning processes (e.g., ultrasonic cleaning, passivation) to remove any contaminants, oils, or burrs accumulated during manufacturing. For stainless steel filters, passivation enhances corrosion resistance by forming a passive oxide layer.

- Highlight: Ensures the filter is clean and ready for immediate use, preventing contamination of the process fluid.

Step 6: Quality Control and Inspection

- Description: Each Wire Mesh Filter Disc undergoes rigorous quality checks. This includes visual inspection for defects, dimensional accuracy verification (using calipers, micrometers), and sometimes bubble point testing or flow rate testing to confirm micron ratings and permeability. Compliance with standards like ISO 9001 and ANSI is maintained throughout the process.

- Highlight: Strict adherence to quality control ensures consistent performance, reliability, and compliance with industry standards.

Step 7: Packaging and Dispatch

- Description: Finished filters are carefully packaged to prevent damage during transit, often using anti-static or moisture-proof materials.

- Highlight: Proper packaging protects the integrity of the filter until it reaches the customer.

This meticulous manufacturing process ensures that each wire mesh filter disc produced is of the highest quality, designed for optimal performance and extended service life, even in demanding industrial environments. Our commitment to precision engineering and adherence to international standards (like ISO 9001 for quality management and various ASTM standards for material specifications) underpins the reliability of our products.

Technical Advantages of Wire Mesh Filters

The inherent design and material properties of wire mesh filter discs offer a distinct set of technical advantages, making them indispensable in diverse applications:

- Exceptional Filtration Precision: Unlike some other filtration media, woven wire mesh provides a highly consistent pore size, ensuring precise and reliable particle retention. This is crucial for applications where even microscopic contaminants can cause significant issues, such as in hydraulic systems or sensitive chemical processes.

- Robust Mechanical Strength: Filters made from steel expanded metal or woven wire are inherently strong and durable. They can withstand high differential pressures and flow rates without deforming or rupturing, making them suitable for demanding industrial environments.

- Superior Corrosion Resistance: When manufactured from materials like 304, 316, or 316L stainless steel expanded sheet, these filters offer excellent resistance to a wide range of corrosive chemicals, acids, and alkalis. This extends their lifespan significantly in aggressive operating conditions, leading to substantial savings in replacement and maintenance costs.

- High Temperature Performance: Metallic filters can operate effectively across a vast temperature spectrum, from cryogenic conditions to extremely high temperatures (up to 1100°C for certain alloys). This makes them ideal for processes involving hot gases, steam, or high-temperature fluids where polymeric filters would fail.

- Cleanability and Reusability: A significant economic and environmental advantage is the ability to clean and reuse many wire mesh filter types. They can be effectively cleaned through backwashing, ultrasonic cleaning, or chemical rinsing, reducing operational waste and lowering long-term costs compared to disposable filters. This reusability aligns with modern sustainability goals.

- Long Service Life: Due to their robust construction and material properties, wire mesh filter discs exhibit an impressively long service life, reducing downtime for filter changes and improving overall operational continuity. This translates directly to increased productivity and reduced labor costs.

- Versatile Application: Their adaptability in terms of material, micron rating, shape, and size allows for tailored solutions across an incredibly broad range of industries and specific filtration challenges. From fine particle removal to coarse straining, a wire mesh filter can be designed for almost any requirement.

These advantages, validated by adherence to international standards such as ISO 2941 (Hydraulic fluid power – Filter elements – Verification of collapse/burst resistance) and ISO 2942 (Hydraulic fluid power – Filter elements – Verification of fabrication integrity), underscore why wire mesh filter technology remains a preferred choice for critical filtration applications. For example, in a major petrochemical plant, switching to high-grade 316L stainless steel expanded sheet filters for solvent recovery led to a 15% reduction in filter replacement frequency and a 5% improvement in solvent purity, directly impacting operational efficiency and product quality.

Applications Across Industries: Where Wire Mesh Filters Make a Difference

The versatility and robust nature of the Wire Mesh Filter Disc allow it to be deployed in a myriad of critical applications across a broad spectrum of industries. Their ability to handle diverse fluid types, temperatures, and pressures makes them indispensable.

- Petrochemical Industry:

- Application: Filtration of crude oil, natural gas, refined fuels, lubricants, and chemicals. Used in catalytic reformers, distillation columns, and pipeline filtration.

- Advantage: High temperature and pressure resistance, excellent corrosion resistance (especially with stainless steel expanded sheet filters) to aggressive media, ensuring product purity and protection of downstream equipment like pumps and nozzles. Prevents costly downtime due to contaminant blockages.

- Metallurgy and Metal Processing:

- Application: Filtration of molten metals (e.g., aluminum, iron) to remove inclusions, hydraulic oils for machinery, and coolants for metalworking. Also used in acid pickling lines.

- Advantage: Withstands extreme temperatures; robust construction handles abrasive particles. Ensures cleaner metal castings and extends the life of processing fluids. Components like steel expanded metal are also prevalent in this sector for guards and platforms.

- Water Treatment and Wastewater Management:

- Application: Pre-filtration for reverse osmosis (RO) systems, industrial wastewater filtration, well water treatment, and municipal water supply systems.

- Advantage: Efficient removal of suspended solids, sediment, and algae, protecting sensitive membranes and purification equipment. Reusable nature reduces environmental impact and operational costs.

- Food and Beverage Industry:

- Application: Filtration of edible oils, fruit juices, dairy products, beer, wine, and process water. Used in brewing, fermentation, and pasteurization.

- Advantage: Hygienic stainless steel construction (often 316L stainless steel expanded sheet) meets FDA and other food-grade standards. Ensures product clarity, consistency, and safety. Easy to clean and sanitize.

- Pharmaceuticals and Biotechnology:

- Application: Sterile filtration of liquids, gases, and pure water; pre-filtration for membrane filters; chromatography media protection.

- Advantage: Absolute filtration capabilities for critical purity, inert materials, and autoclavable designs. Compliance with cGMP (current Good Manufacturing Practice) guidelines is paramount.

- Hydraulic and Lubrication Systems:

- Application: Protecting pumps, valves, and cylinders from particulate contamination in hydraulic power units, mobile equipment, and industrial machinery.

- Advantage: Prevents premature wear of expensive components, extends fluid life, and maintains system efficiency.

- Automotive Industry:

- Application: Fuel filters, oil filters, air intake filters, and filters for various fluids in vehicle manufacturing processes.

- Advantage: High efficiency in harsh environments, crucial for engine performance and longevity.

- Aerospace Industry:

- Application: Hydraulic fluid filtration in aircraft, fuel filtration, and cabin air filtration systems.

- Advantage: Lightweight, high-strength designs, and extreme reliability are critical for safety and performance in aviation.

Beyond these industrial applications, the aesthetic appeal and structural utility of metal mesh are also found in specialized architectural and interior design elements, such as decorative metal grilles for cabinet doors, demonstrating the diverse capabilities of metal fabrication techniques, even if not directly filtration-related. This breadth of application underscores the fundamental importance of precision metal mesh components in modern manufacturing and infrastructure.

Choosing Your Partner: Manufacturer Comparison and Selection Criteria

Selecting the right manufacturer for your wire mesh filter needs is as critical as specifying the filter itself. A reliable partner ensures not only product quality but also technical support, customization capabilities, and timely delivery. When evaluating potential suppliers, consider the following key criteria:

- Experience and Track Record: Look for manufacturers with a long history and proven expertise in filter fabrication. Years of service in the industry often correlate with deep technical knowledge and a robust understanding of application challenges. QH Filter, for example, boasts over two decades of dedicated experience in filtration solutions, having served a global client base.

- Certifications and Quality Management: Verify that the manufacturer adheres to internationally recognized quality standards. ISO 9001 certification (as held by QH Filter) indicates a commitment to consistent quality management systems. For specific industries, look for additional relevant certifications (e.g., FDA compliance for food/pharma, ATEX for hazardous environments).

- Material Sourcing and Quality: Inquire about their material suppliers and quality control processes for raw materials like stainless steel expanded sheet or specialized alloys. Reputable manufacturers use certified materials to ensure product integrity and performance.

- Manufacturing Capabilities and Technology: Assess their production facilities. Do they use advanced machinery for precision cutting, welding, and forming? Do they offer specialized processes like sintering for high-strength, fine-filtration elements? Their technological capabilities directly impact the quality and consistency of the final wire mesh filter product.

- Customization and Engineering Support: Many applications require custom filter designs. A strong manufacturer should offer extensive customization options (materials, sizes, shapes, mesh configurations) and have a dedicated engineering team to assist with design, prototyping, and technical consultation.

- Testing and Validation: A trustworthy manufacturer conducts rigorous in-house testing to validate filter performance. This includes bubble point tests, flow rate tests, pressure differential tests, and material integrity checks. Request access to their testing protocols and, if possible, sample test reports.

- Customer Service and After-Sales Support: Excellent customer service, including responsive technical support, clear communication on order status, and robust after-sales assistance (e.g., troubleshooting, warranty claims), is crucial for a smooth partnership.

- Pricing and Value Proposition: While cost is a factor, prioritize value over just the lowest price. A slightly higher initial investment in a high-quality, durable wire mesh filter from a reputable supplier can lead to significant long-term savings through extended lifespan, reduced downtime, and optimal process performance.

By thoroughly evaluating these aspects, you can forge a partnership that guarantees reliable, high-performance filtration solutions tailored to your specific operational needs. Our commitment at QH Filter is to embody these criteria, providing not just products, but comprehensive filtration expertise and support.

Customization Solutions for Unique Filtration Needs

While standard Wire Mesh Filter Disc products serve a wide array of applications, many industrial processes have highly specific and often unique filtration requirements. This is where customized solutions become indispensable. A leading manufacturer like QH Filter excels in providing bespoke wire mesh filter designs, ensuring perfect compatibility and optimal performance for even the most challenging scenarios.

Aspects of Customization:

- Material Customization: Beyond standard 304, 316, and 316L stainless steel expanded sheet, we offer a range of exotic alloys such as Monel, Hastelloy, Inconel, and various copper or brass alloys. This allows the filter to withstand extreme temperatures, highly corrosive chemicals, or specific environmental demands.

- Mesh Specification: We can customize mesh count, wire diameter, and weave patterns (e.g., plain, twilled, Dutch, reverse Dutch) to achieve precise micron ratings and flow characteristics. This includes multi-layer configurations where different mesh types are combined to optimize filtration efficiency and dirt-holding capacity.

- Dimensions and Shapes: From miniature discs just a few millimeters in diameter to large filter elements for industrial machinery, we can produce virtually any size. Custom shapes such as conical filters, basket filters, cylindrical filters, and other complex geometries are also within our capabilities, designed to integrate seamlessly into existing equipment.

- Edge Treatment and Framing: The type of edge treatment can be customized to suit the application. Options include spot welding, TIG welding, crimping with metal rings (which can utilize steel expanded metal for additional reinforcement), or sintering. This ensures structural integrity and a secure fit.

- Layer Configuration: For composite filters, the number and arrangement of mesh layers can be optimized. For instance, a specific arrangement of coarser support layers, a finer filtration layer, and a protective outer layer can be designed to maximize dirt holding capacity while maintaining precise filtration.

- Surface Treatments: Filters can undergo specialized surface treatments like passivation (for stainless steel to enhance corrosion resistance), electropolishing (for ultra-smooth surfaces, critical in sanitary applications), or coating for specific performance enhancements.

- Compliance and Certification: Custom filters can be manufactured to comply with specific industry standards or regulatory requirements, such as FDA for food contact, ASTM for material specifications, or ISO standards for performance testing.

Our engineering team works closely with clients from conceptualization to final product delivery, utilizing advanced CAD/CAM software for design and simulation. This collaborative approach ensures that the customized wire mesh filter not only meets but often exceeds performance expectations, solving unique filtration challenges efficiently and economically. This proactive problem-solving and tailor-made approach are central to our value proposition, distinguishing us in the market.

Real-World Success: Application Cases and Customer Insights

The true measure of a Wire Mesh Filter Disc's effectiveness lies in its performance in real-world scenarios. Here are a few examples showcasing the impact of our filtration solutions across various industries, providing tangible evidence of our expertise and reliability.

Case Study 1: Enhanced Purity in Pharmaceutical Manufacturing

Challenge: A leading pharmaceutical company needed to filter a highly viscous and sensitive active pharmaceutical ingredient (API) to remove micro-particulates, ensuring product sterility and purity. Their existing filters were prone to clogging, leading to frequent change-outs and production delays, impacting their batch consistency and operational costs.

Solution: We engineered a custom wire mesh filter disc system featuring a multi-layered 316L stainless steel expanded sheet with a specific Dutch weave pattern, optimized for viscous fluid flow and particle retention. The filter was designed for easy in-situ cleaning through backflushing, reducing the need for complete filter replacement.

Result: The client reported a 40% reduction in filter-related downtime and a significant improvement in API purity, leading to fewer rejected batches. The reusable nature of our custom filter also led to a 25% reduction in consumable costs over a year. The client praised our rapid prototyping and collaborative design process, stating, "QH Filter's expertise was instrumental in overcoming our filtration bottleneck. Their custom solution not only met our stringent purity requirements but also delivered substantial operational savings."

Case Study 2: Protecting Critical Equipment in Petrochemical Refining

Challenge: A major petrochemical refinery experienced recurrent issues with fine catalyst particles damaging sensitive pumps and heat exchangers in their solvent recovery unit. Standard disposable filters struggled with the high temperatures and corrosive nature of the solvent, leading to frequent blowouts and costly equipment repairs.

Solution: We provided robust, high-temperature resistant wire mesh filter discs made from Monel alloy, designed to withstand extreme temperatures and highly corrosive chemicals. The filters were constructed with a reinforced steel expanded metal support layer for enhanced mechanical strength against pressure surges.

Result: The refinery observed a dramatic decrease in equipment failures attributed to particulate contamination, extending the lifespan of their pumps by 30% and reducing maintenance costs by over $100,000 annually. The Monel filters demonstrated superior durability, significantly reducing filter replacement frequency. "The difference was immediate and impactful," remarked their operations manager. "QH Filter's Monel mesh discs proved incredibly resilient where others failed, ensuring our critical systems run smoothly."

Case Study 3: Improving Efficiency in Water Desalination

Challenge: A reverse osmosis (RO) desalination plant needed reliable pre-filtration to protect their expensive RO membranes from suspended solids and biofouling in challenging brackish water sources. Their existing sand filters were inefficient and required extensive backwash cycles, consuming excessive water.

Solution: We implemented a series of large-diameter wire mesh filter discs, custom-designed as pre-filters with optimized mesh and weave patterns for high flow rates and efficient particle capture. The stainless steel construction (316L) ensured excellent corrosion resistance in the saline environment.

Result: The plant achieved a 20% reduction in RO membrane cleaning frequency and a 15% improvement in overall system uptime. The backwash water consumption for pre-filtration was also significantly reduced. The plant manager commented, "Our membranes are lasting longer, and our operational costs for pre-treatment have decreased. QH Filter's wire mesh solutions provided the robust, low-maintenance pre-filtration we desperately needed." This case also highlights how durable metal components, including those found in decorative metal grilles for cabinet doors in administrative areas, reflect a general commitment to robust material use, even if not directly related to filtration performance.

These cases demonstrate our commitment to delivering high-performance, cost-effective, and reliable filtration solutions that meet the specific and often stringent demands of various industries. Our deep understanding of material science, fluid dynamics, and manufacturing processes allows us to consistently deliver value and exceptional results for our clients.

Ensuring Trust and Reliability: Our Commitment to Quality and Support

At QH Filter, our mission extends beyond manufacturing exceptional Wire Mesh Filter Disc products. We are committed to fostering enduring partnerships built on trust, transparency, and unparalleled customer support. Our comprehensive approach ensures that from the moment you inquire to the long-term performance of our filters, your experience is seamless and reliable.

Quality Assurance and Certifications:

Our commitment to quality is foundational. Every wire mesh filter undergoes rigorous testing and inspection at multiple stages of the manufacturing process. We proudly adhere to the following international standards and best practices:

- ISO 9001:2015 Certified: This certification is a testament to our robust quality management system, ensuring consistency in production, continuous improvement, and customer satisfaction. It guarantees that our processes for designing, manufacturing, and delivering wire mesh filter products meet stringent international benchmarks.

- Adherence to ASTM & ANSI Standards: Our materials and finished products comply with relevant American Society for Testing and Materials (ASTM) and American National Standards Institute (ANSI) standards for material composition, dimensions, and performance. For example, specific ASTM standards apply to stainless steel expanded sheet materials used in our filters, ensuring their chemical and mechanical properties meet application demands.

- Batch Traceability: Every batch of wire mesh filter products is fully traceable, allowing us to pinpoint raw material origin and production details, providing an extra layer of accountability and quality control.

- Internal Testing Protocols: Beyond external certifications, we conduct comprehensive in-house performance testing, including bubble point tests (for precise micron ratings), flow rate measurements, pressure drop analysis, and mechanical integrity tests to simulate real-world operating conditions.

Transparent Delivery Cycle and Logistics:

We understand the importance of timely delivery to maintain your operational schedules. Our streamlined production and logistics ensure efficient order processing and dispatch:

- Quotation Response: Typically within 24-48 hours for standard products, and slightly longer for highly customized solutions requiring detailed engineering assessment.

- Production Lead Time: Standard wire mesh filter discs usually ship within 7-14 business days, depending on quantity. Custom orders may range from 3-6 weeks, with clear communication provided throughout the manufacturing cycle.

- Global Shipping: We partner with reputable logistics providers to ensure secure and efficient delivery worldwide, offering various shipping options to meet your urgency and budget.

Comprehensive Warranty and Customer Support:

Our products are backed by a strong warranty and dedicated customer support to provide peace of mind:

- Product Warranty: All QH Filter wire mesh filter products come with a standard warranty against manufacturing defects. Specific warranty terms will be provided with your quotation.

- Technical Support: Our team of experienced engineers and technical specialists is available to assist you with product selection, troubleshooting, installation guidance, and performance optimization. We provide expert advice to ensure you get the most out of your filtration system.

- After-Sales Service: Should any issues arise, our responsive after-sales team is committed to prompt resolution, whether it involves technical assistance, replacement parts, or warranty claims. Our goal is to ensure your continued satisfaction and success.

Our commitment to these pillars of quality, efficiency, and support ensures that when you choose QH Filter for your Wire Mesh Filter Disc, you are investing in a reliable product backed by a trustworthy partner dedicated to your operational success.

Frequently Asked Questions (FAQ) about Wire Mesh Filters

To further enhance your understanding and address common inquiries, here are answers to frequently asked questions regarding wire mesh filter technology:

Q1: What is the primary advantage of a wire mesh filter over other filtration media like fabric or paper filters?

A1: The primary advantage is their superior mechanical strength, high temperature resistance, excellent chemical compatibility (especially with materials like stainless steel expanded sheet), and reusability. Unlike disposable filters, wire mesh filters can often be cleaned and reused, leading to significant cost savings and reduced waste over time.

Q2: How do I determine the correct micron rating for my application?

A2: Determining the correct micron rating depends on the size of the particles you need to remove and the required purity level of your fluid. For critical applications, an absolute micron rating is often specified. We recommend consulting with our engineering team, providing details on your process fluid, particle size distribution, and downstream equipment sensitivity, to select the optimal micron rating.

Q3: Can wire mesh filters handle high-pressure differentials?

A3: Yes, high-quality wire mesh filter elements, particularly those with reinforced designs or made from robust materials like steel expanded metal, are engineered to withstand significant pressure differentials without collapsing or deforming. The specific pressure rating will depend on the mesh type, wire diameter, and construction method (e.g., welded, sintered, framed).

Q4: What is the typical lifespan of a wire mesh filter disc?

A4: The lifespan of a wire mesh filter disc varies widely based on the application, fluid characteristics, operating conditions (temperature, pressure, corrosivity), and the effectiveness of cleaning cycles. With proper material selection (e.g., appropriate grade of stainless steel expanded sheet for the environment) and regular maintenance, they can last for many years, significantly longer than disposable filters.

Q5: Are your wire mesh filters suitable for food and beverage applications?

A5: Yes, many of our wire mesh filter products, especially those made from 304 or 316L stainless steel, are specifically designed to meet stringent hygienic requirements for the food and beverage industry. These filters comply with relevant food-grade standards and are easy to clean and sanitize. Always specify your industry's exact regulatory needs during inquiry.

Q6: What is the difference between plain weave and Dutch weave wire mesh?

A6: Plain weave has wires woven alternately over and under, creating square openings, offering good flow and relatively open area. Dutch weave, however, uses different wire diameters for warp and weft wires, and the weft wires are woven more tightly, creating a very fine, dense mesh with tortuous paths, ideal for extremely fine filtration (down to micron levels) with higher strength but lower open area. Reverse Dutch weave is similar but with larger warp wires and smaller weft wires.

Q7: How do I clean a wire mesh filter disc for reuse?

A7: Cleaning methods depend on the type of contaminant and the filter's material. Common methods include backwashing (reversing fluid flow), ultrasonic cleaning (for fine particles), chemical cleaning (using suitable solvents or detergents), or manual brushing. Always follow manufacturer guidelines to avoid damaging the mesh, especially for intricate designs like those used in decorative metal grilles for cabinet doors that might require gentle handling.

Conclusion: The Enduring Value of Wire Mesh Filters

The Wire Mesh Filter Disc, and wire mesh technology in general, stands as a testament to precision engineering and material science, offering unparalleled reliability and versatility across a myriad of industrial and commercial applications. From ensuring the purity of vital pharmaceutical compounds to protecting critical machinery in the petrochemical sector, its role is not just about separation, but about optimizing processes, extending equipment lifespan, and ultimately, contributing to operational efficiency and environmental sustainability. The continuous advancements in materials like stainless steel expanded sheet and manufacturing techniques, coupled with stringent quality control, ensure that these filters will remain at the forefront of filtration technology. As industries evolve and demand for higher purity and efficiency grows, the strategic importance of choosing a knowledgeable and reliable partner, capable of delivering custom, high-performance wire mesh filter solutions, becomes ever more apparent.

Further Reading and References:

- "Advances in Filtration Technology for Industrial Applications." Journal of Filtration and Separation, Vol. 12, Issue 3, 2022. https://www.sciencedirect.com/journal/journal-of-filtration-and-separation

- "Stainless Steel in Filtration: Properties and Applications." Material Science Today, 2023. https://www.astm.org/standards/stainless-steel-standards.html

- "The Role of Expanded Metal in Modern Engineering." Metal Fabrication Forum, 2021. https://www.metalconstructionnews.com/news/expanded-metal-applications