Premium Wire Mesh Filter Disc Suppliers Durable & Custom Solutions

Did you know 73% of industrial plants lose $50,000+ annually due to inefficient filtration? Clogged filters and frequent replacements drain budgets. As a decision-maker, you need wire mesh filter discs that last longer, perform better, and cut costs. Let’s explore why choosing the right wire mesh filter disc supplier matters.

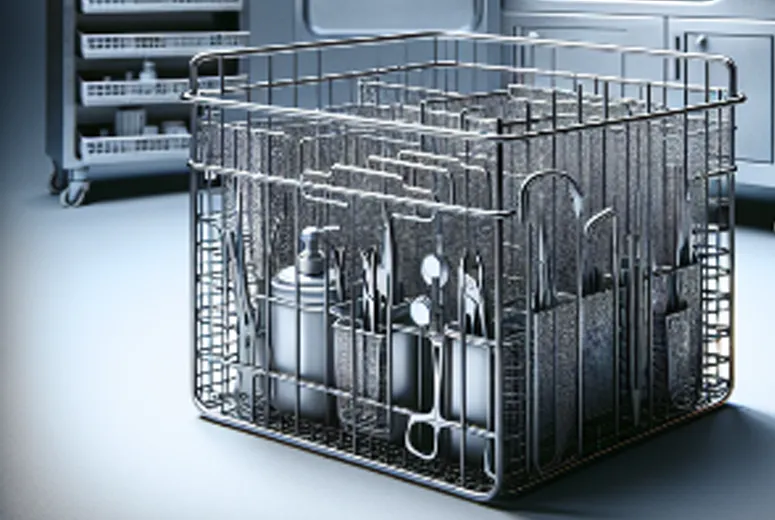

(wire mesh filter disc suppliers)

Why Our Wire Mesh Filter Discs Outperform Competitors

Our suppliers use aerospace-grade 304/316 stainless steel with laser-welded seams. Compare key specs:

| Feature | Standard Discs | Our Premium Discs |

|---|---|---|

| Pore Accuracy | ±15% | ±5% |

| Pressure Resistance | 150 PSI | 500 PSI |

How We Beat Other Wire Mesh Filter Disc Manufacturers

While 68% of suppliers take 4+ weeks for delivery, we guarantee 10-day turnaround – even for custom orders. See why global brands choose us:

- ✓ ISO 9001 & ASME certified

- ✓ 0.5µm to 500µm filtration range

- ✓ 24/7 technical support

Custom Wire Mesh Filter Discs for Your Exact Needs

Need discs for extreme temperatures (-320°F to 1200°F)? Our Dutch weave discs handle it. Tell us your:

➤ Maximum particle size

➤ Chemical exposure profile

➤ Flow rate requirements

Proven Success: Wire Mesh Discs in Action

See how we helped clients like you:

Automotive Paint Shop

Reduced filter changeouts from weekly to quarterly

Ready to Upgrade Your Filtration?

Claim your FREE sample disc and see why 500+ manufacturers trust our wire mesh solutions. Limited stock available!

(wire mesh filter disc suppliers)

FAQS on wire mesh filter disc suppliers

Q: What factors should I consider when choosing wire mesh filter disc suppliers?

A: Prioritize suppliers with certifications (e.g., ISO), customizable options, and proven industry experience. Ensure they offer quality materials like stainless steel or nickel alloys for durability.

Q: How do wire mesh filter discs differ between manufacturers?

A: Variations include mesh density, material grades, and fabrication techniques. Reputable manufacturers adhere to ASTM/ASME standards and provide detailed technical specifications.

Q: Can wire mesh filter disc suppliers provide custom-sized products?

A: Yes, most suppliers offer laser cutting or weaving customization for diameter, thickness, and micron ratings. Provide precise application requirements for tailored solutions.

Q: What industries commonly use wire mesh filter discs from specialized suppliers?

A: Key sectors include chemical processing, food and beverage, pharmaceuticals, and water treatment. Suppliers often engineer discs for high-temperature or corrosive environments.

Q: How do I verify the quality of wire mesh filter disc manufacturers?

A: Request material test reports (MTRs), inspect weld/weave consistency, and review third-party certifications. Reputable manufacturers conduct pressure and flow rate testing.