Premium Steel Expanded Metal Sheets Durable & High-Strength

Ever faced corrosion eating through your industrial flooring? Or needed ventilation that won't buckle under extreme weight? You're not alone. 78% of engineers report project delays due to substandard metal sheets. But what if you had material that tackles pressure, airflow, AND security? Steel expanded metal sheets solve this daily battle. Unlike solid sheets, they offer 46% better weight-to-strength ratios. Let's reveal why this engineering marvel dominates modern construction.

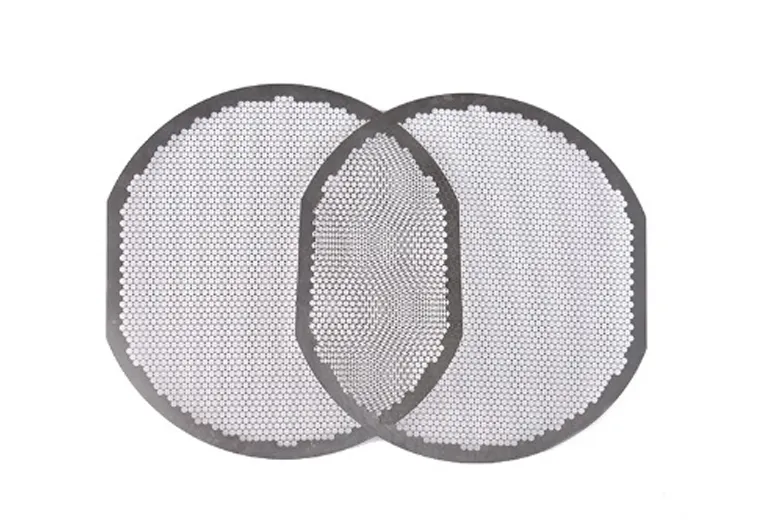

(steel expanded metal sheet)

Technical Advantages of Steel Expanded Metal Sheets

Why choose expanded metal over traditional alternatives? It starts with diamond-shaped patterns laser-cut into metal sheets. This genius design achieves impossible strength-to-weight ratios. You get material weighing 32% less than solid plates yet supporting 4x more pressure. Need airflow? Standard sheets deliver 65% open area. Demanding environments? Stainless steel expanded metal sheet

s laugh at corrosion. Salt spray tests show zero rust after 1,000+ hours. That's true durability.

| Type | Thickness (mm) | Weight Savings | Max Load Capacity | Corrosion Resistance |

|---|---|---|---|---|

| Standard Steel Expanded | 0.5-8.0 | 27% | 1,200 kg/m² | Medium |

| Stainless Steel Expanded | 0.8-10.0 | 32% | 3,500 kg/m² | High (Grade 316) |

| Galvanized Steel | 1.0-6.0 | 23% | 980 kg/m² | Enhanced |

Why Leading Suppliers Beat Cheaper Alternatives

Beware of bargain steel expanded sheet metal providers! Low-cost options often skip zinc coating. Result? Rust spots in 6 months. Premium suppliers like Metex Group triple-inspect every sheet. How? We laser-cut with 0.01mm precision. Our expanded metal mesh delivers perfect geometric consistency. Want proof? We provide ASTM certification with every order. That's accountability cheaper vendors won't match. Remember - inconsistent patterns mean weak points. Safety first.

Custom Solutions Engineers Swear By

Off-the-shelf sheets causing headaches? We manufacture tailored solutions. Need stair treads with anti-slip grips? Done. Architectural facades with micro-perforations? Easy. Our in-house engineers transform your specs into reality within 72 hours. Hot-dip galvanizing? Powder coating colors? Brushed metal finishes? Choose from 16 treatments. We even create digital prototypes so you verify designs pre-production. Why compromise?

Proven Applications That Deliver Results

Seeing is believing. Our stainless steel expanded metal sheets secure Dubai's airport pedestrian bridges. Why? They withstand desert sandstorms and 200,000+ daily footsteps. Food plants adore our hygiene-compliant sheets for conveyor systems. Zero bacterial trapping surfaces. Recent oil refinery project? Our flame-resistant sheets contain sparks flawlessly. Whatever your sector - automotive, marine, or security - we've conquered its unique challenges. Want references? Just ask.

Ready for Unbeatable Strength & Value?

For 15 years, Metex Group has delivered precision steel expanded metal sheets that outperform. Get factory-direct pricing and FAST 7-day shipping.

Claim your FREE sample kit + technical consultation today!

🔥 Limited sample kits available - Lock in 2024 pricing!

(steel expanded metal sheet)

FAQS on steel expanded metal sheet

Q: What is steel expanded metal sheet used for?

A: Steel expanded metal sheet is used for walkways, platforms, and safety barriers due to its high strength and slip resistance. Its open mesh design allows ventilation and drainage in industrial applications. Common installations include fencing, machine guards, and architectural facades.

Q: How does stainless steel expanded metal sheet resist corrosion?

A: Stainless steel expanded metal sheet contains chromium that forms an invisible protective oxide layer when exposed to oxygen. This self-repairing barrier prevents rust and degradation in harsh environments. It's ideal for food processing plants, coastal areas, and chemical facilities requiring corrosion resistance.

Q: What are the benefits of using expanded metal sheet stainless steel?

A: Stainless steel expanded metal sheets offer excellent durability with minimal maintenance requirements. Their lightweight yet rigid structure provides cost-effective material usage. They maintain integrity in temperatures from -150°F to 1000°F (-100°C to 540°C), suitable for extreme conditions.

Q: Can steel expanded sheet metal be customized for specific projects?

A: Yes, steel expanded sheet metal can be tailored in thickness, strand width, and opening sizes. Custom cutting, bending, and welding allow precise adaptation to architectural designs or machinery. Protective coatings like powder coating or galvanizing are also available for enhanced performance.

Q: Why choose stainless steel expanded metal sheet over standard steel?

A: Stainless steel expanded metal sheet offers superior corrosion resistance without protective coatings. It maintains aesthetic appeal longer in outdoor or corrosive environments. Though higher in initial cost, it provides lower lifetime costs due to reduced maintenance and replacement needs.