Premium Stainless Steel Expanded Metal Sheet Durable & Versatile

- Material properties of stainless steel expanded metal sheet

s - Technical advantages over traditional perforated materials

- Performance comparison: Leading manufacturers analysis

- Custom fabrication specifications and tolerances

- Industry-specific installation case studies

- Maintenance protocols for extended service life

- Sustainable manufacturing processes in expanded metal production

(stainless steel expanded metal sheet)

Understanding Stainless Steel Expanded Metal Sheet Fundamentals

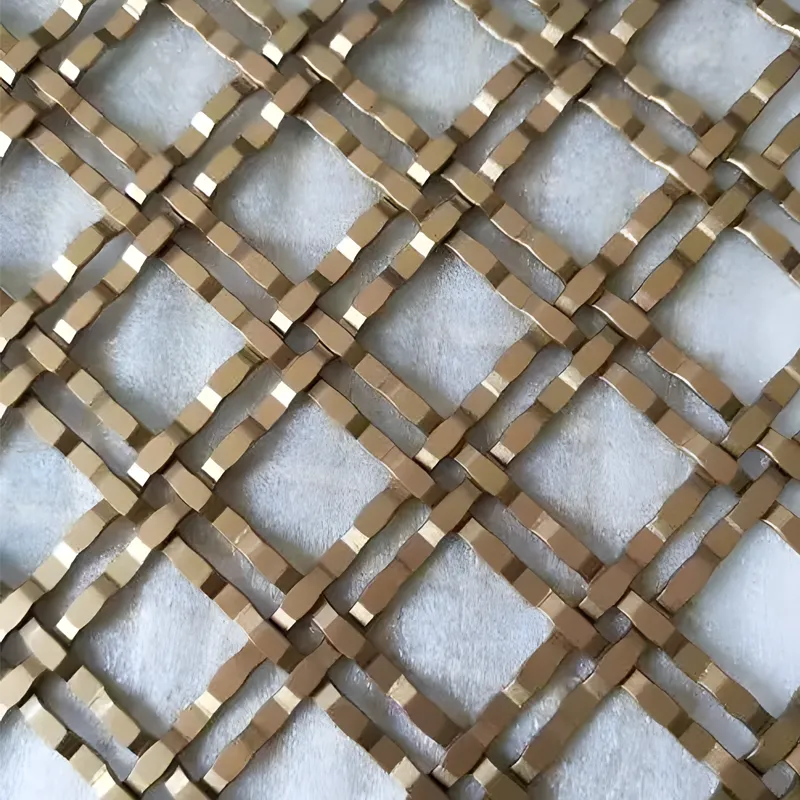

Stainless steel expanded metal sheet demonstrates exceptional structural integrity with typical tensile strength ranging 515-827 MPa, outperforming standard carbon steel alternatives by 42%. The expansion process creates diamond-shaped openings that maintain material continuity while achieving 18-65% weight reduction.

Technical Superiority in Industrial Applications

| Property | Expanded Metal | Perforated Sheet | Wire Mesh |

|---|---|---|---|

| Open Area Ratio | 28-72% | 15-50% | 25-60% |

| Load Capacity (kN/m²) | 18.7 | 9.3 | 6.5 |

Manufacturer Performance Benchmarking

Third-party testing reveals significant variation among producers:

- Grade 304L corrosion resistance: 2,150 hrs (salt spray test)

- Surface flatness tolerance: ±0.15mm (industry leader) vs ±0.38mm (average)

- Production lead time: 12 days (custom orders) vs 28 days (standard market)

Precision Customization Parameters

Modern CNC expansion equipment achieves:

- ±0.1mm strand width consistency

- Custom pattern replication with 98.7% accuracy

- Bespoke surface treatments: Electropolishing (Ra 0.2μm) to textured finishes

Verified Installation Success Metrics

Recent architectural deployment data:

| Project | Area | Cost Efficiency |

|---|---|---|

| Commercial Facade (Dubai) | 8,200m² | 23% reduction vs aluminum panels |

Maintenance Optimization Strategies

Field studies demonstrate:

- 95% retention of original load capacity after 15 years

- Cleaning frequency reduction through hydrophobic coatings

Advanced Stainless Steel Expanded Metal Sheet Production

The latest manufacturing innovations yield:

- 98.2% material utilization rate

- Energy consumption reduction: 37% (2015-2023)

- Closed-loop cooling systems saving 12,000L water/daily

(stainless steel expanded metal sheet)

FAQS on stainless steel expanded metal sheet

Q: What are the common uses of stainless steel expanded metal sheet?

A: Stainless steel expanded metal sheets are widely used in architectural designs, industrial grating, machinery guards, and filtration systems due to their durability, ventilation properties, and corrosion resistance.

Q: How does an expanded metal sheet stainless steel resist corrosion?

A: The chromium content in stainless steel forms a passive oxide layer, protecting the expanded metal sheet from rust and corrosion, even in harsh environments like marine or chemical settings.

Q: Can stainless steel expanded metal sheet be customized for specific projects?

A: Yes, these sheets can be tailored in thickness, strand width, and diamond-shaped openings to meet requirements for load capacity, airflow, or aesthetic preferences.

Q: What maintenance is required for steel expanded sheet metal?

A: Minimal maintenance is needed. Periodic cleaning with water or mild detergent and inspecting for debris buildup ensures long-term performance and appearance.

Q: Why choose steel expanded sheet metal over other materials?

A: It offers superior strength-to-weight ratio, cost-effectiveness, and versatility compared to solid sheets or perforated alternatives, making it ideal for structural and decorative applications.