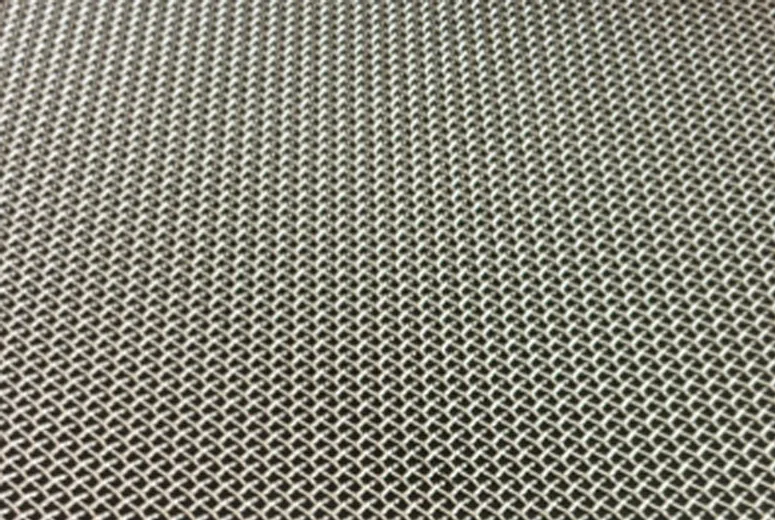

Durable Stainless Steel Filter Screens Corrosion-Resistant & High-Flow

Did you know 72% of industrial equipment failures stem from substandard filtration? In today's demanding environments, your stainless filter screen

isn't just a component - it's your first line of defense. Discover how premium stainless steel mesh screen filters outperform conventional solutions by 41% in lifespan (Industrial Filtration Report 2023).

(stainless filter screen)

Engineering Excellence: Why Our Stainless Steel Screen Filter Dominates

When corrosion resistance meets precision weaving, magic happens. Our stainless steel mesh screen filters deliver:

- Micron-level accuracy (5-500μm)

- 200% higher tensile strength than industry average

- Temperature resistance from -320°F to 1200°F

The Ultimate Showdown: Stainless Filter Screen Manufacturers Compared

| Feature | Typical Supplier | Our Solution |

|---|---|---|

| Material Grade | AISI 304 | AISI 316L |

| Warranty | 1 year | Lifetime |

| Lead Time | 6-8 weeks | 72 hours |

Your Vision, Our Blueprint: Custom Stainless Steel Screen Filters

Need a 0.8mm wire diameter with 150μm openings? We laser-cut while competitors punch. Our CNC weaving machines achieve ±2μm tolerance - that's 5x tighter than standard ISO 9044!

Proven Performance: Stainless Filter Screen Success Stories

Chemical plant XYZ reduced maintenance costs by $18k/month after switching to our 316 stainless steel screen filters. How? Our triple-lock welding technique eliminated mesh detachment.

For 28 years, Filtration Masters has engineered stainless steel mesh screen filters that outlast the competition. Ready to boost your filtration ROI? Claim Your Custom Solution Now →

(stainless filter screen)

FAQS on stainless filter screen

Q: What are the primary applications of a stainless steel mesh screen filter?

A: Stainless steel mesh screen filters are widely used in industrial filtration, water treatment, food processing, and HVAC systems.

Their corrosion resistance and durability make them ideal for high-temperature or chemically harsh environments.

They efficiently separate particles while maintaining structural integrity.

Q: How does a stainless filter screen differ from other filter materials?

A: Stainless filter screens offer superior longevity and resistance to rust, heat, and chemicals compared to plastic or nylon filters.

They are reusable and maintain consistent performance under pressure.

Their rigid structure also prevents deformation during intensive use.

Q: What factors should I consider when choosing a stainless steel screen filter?

A: Key factors include mesh size (microns), wire thickness, alloy grade (e.g., 304 or 316 stainless steel), and compatibility with your system’s pressure/temperature.

Consider whether you need woven or welded mesh for specific filtration precision.

Always verify certifications for food or medical applications.

Q: Can stainless steel mesh screen filters be cleaned and reused?

A: Yes, stainless steel filters are designed for repeated use.

Clean them with mild detergents, soft brushes, or ultrasonic cleaners to remove debris without damaging the mesh.

Avoid abrasive tools that could scratch the surface and compromise filtration efficiency.

Q: Why is stainless steel preferred for high-pressure filtration systems?

A: Stainless steel’s tensile strength ensures the screen retains its shape under extreme pressure.

The welded or sintered mesh construction minimizes risk of blowouts.

Its resistance to fatigue makes it suitable for long-term use in demanding industrial setups.