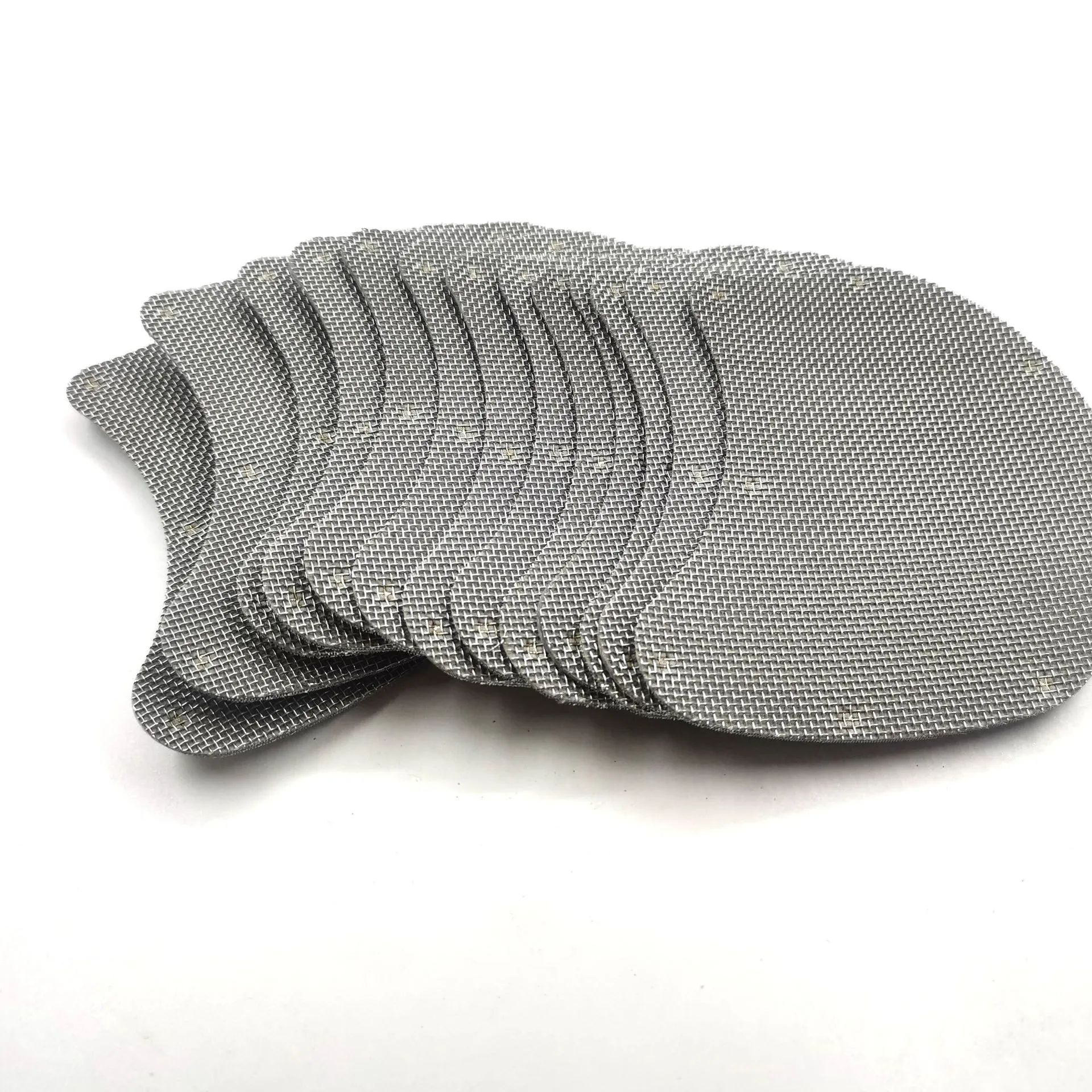

Stainless Steel Mesh Filters High-Flow, Durable & Corrosion-Resistant

Did you know poor filtration costs manufacturers $3.7B annually? Clogged screens. Frequent replacements. Contamination risks. What if your filter could slash maintenance costs while boosting flow rates? Meet the game-changer: stainless steel mesh filters.

(ss mesh filter)

Technical Superiority That Outperforms

Our conical filter stainless steel mesh achieves 99.97% particulate capture at 50 microns. See how we dominate:

| Feature | Standard Filters | Our SS Mesh |

|---|---|---|

| Max Temperature | 400°F | 1200°F |

| Flow Rate | 15 GPM | 38 GPM |

| Lifespan | 6 months | 5+ years |

Head-to-Head: Why We Crush Competitors

While others use 304 stainless, our stainless mesh filter

employs aerospace-grade 316L. Result? 3X corrosion resistance in chloride-rich environments.

- ✓ Laser-welded seams vs. spot welding

- ✓ 0.1mm precision vs. 0.5mm industry standard

Your Industry, Your Filter Solution

Pharma needs 10μm absolute rating? Done. Food processing requires NSF certification? We’ve got it. Our stainless steel mesh filter adapts like liquid metal.

Proven Success: Automotive Case Study

When a Tier 1 supplier switched to our conical filter stainless steel mesh, particulate-related recalls dropped 89%. Maintenance intervals stretched from weekly to quarterly.

Ready for Zero-Compromise Filtration?

Join 1,200+ manufacturers who upgraded last quarter. Limited inventory available – claim your custom SS mesh filter design before Friday!

(ss mesh filter)

FAQS on ss mesh filter

Q: What are the benefits of using a stainless steel mesh filter?

A: Stainless steel mesh filters are corrosion-resistant, durable, and ideal for high-temperature or high-pressure applications. They provide efficient filtration and are easy to clean for repeated use.

Q: How does a conical stainless steel mesh filter improve performance?

A: The conical shape increases surface area, enhancing filtration speed and capacity. Its design minimizes clogging and is perfect for beverages, industrial fluids, or laboratory use.

Q: What applications are stainless mesh filters suitable for?

A: They are widely used in water treatment, chemical processing, food and beverage industries, and HVAC systems. Their versatility suits both residential and industrial settings.

Q: How do I clean a stainless steel mesh filter properly?

A: Rinse with warm water and mild detergent, then gently scrub with a soft brush. Avoid abrasive tools to prevent damaging the mesh structure.

Q: Why choose a conical filter over flat stainless steel mesh filters?

A: Conical filters offer better flow dynamics and debris retention due to their tapered design. They are ideal for applications requiring consistent pressure and extended filter life.