SS 316 Mesh & Wire Mesh | Durable Stainless Steel Netting

Navigating the Industrial Landscape: The Indispensable Role of ss 316 mesh

In the intricate world of industrial filtration, separation, and structural reinforcement, the choice of material is paramount. ss 316 mesh stands out as a superior material, a cornerstone for critical applications demanding exceptional resistance to corrosion, high temperatures, and robust mechanical integrity. As industries like petrochemicals, pharmaceuticals, food processing, and marine engineering continue to evolve, the demand for advanced materials that promise longevity and optimal performance is escalating. Stainless steel mesh, particularly the 316 grade, addresses these stringent requirements by offering unparalleled durability in harsh operating environments. Its unique composition, including molybdenum, significantly enhances its resistance to pitting and crevice corrosion, making it a preferred choice over other stainless steel grades in environments exposed to chlorides or other aggressive chemicals. This comprehensive guide delves into the technical intricacies, vast applications, manufacturing excellence, and market dynamics surrounding stainless steel 316 mesh, providing B2B decision-makers and technical personnel with insights to make informed procurement and engineering choices.

We will explore the prevailing industry trends driving its adoption, dissect its precise technical parameters, elaborate on its sophisticated manufacturing processes, and highlight its distinct advantages. Furthermore, we will present real-world application scenarios, offer a framework for vendor evaluation, and outline the possibilities for bespoke solutions. Our objective is to empower you with a deep understanding of how ss 316 mesh can significantly enhance operational efficiency, extend equipment lifespan, and ensure compliance with the highest industry standards, thereby contributing to sustainable and profitable industrial operations. This material's adaptability extends from fine filtration screens to robust architectural cladding, showcasing its versatility and critical importance across a multitude of sectors that prioritize material excellence and long-term reliability in their infrastructure.

Industry Trends & Technical Parameters of ss 316 mesh

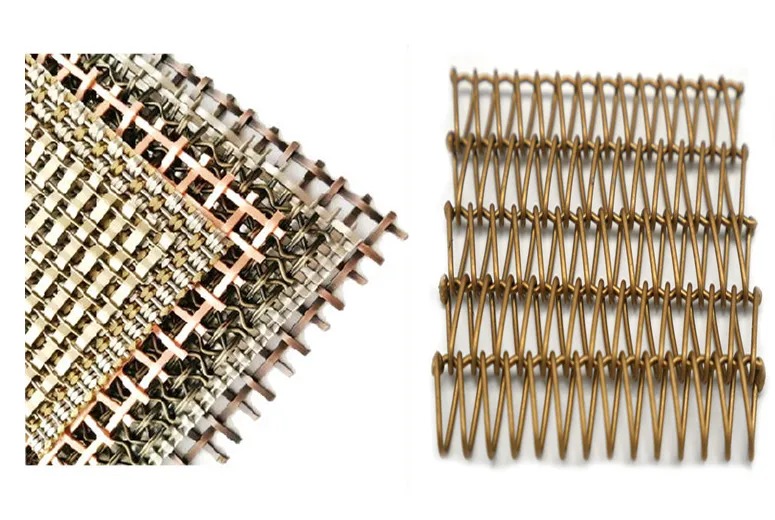

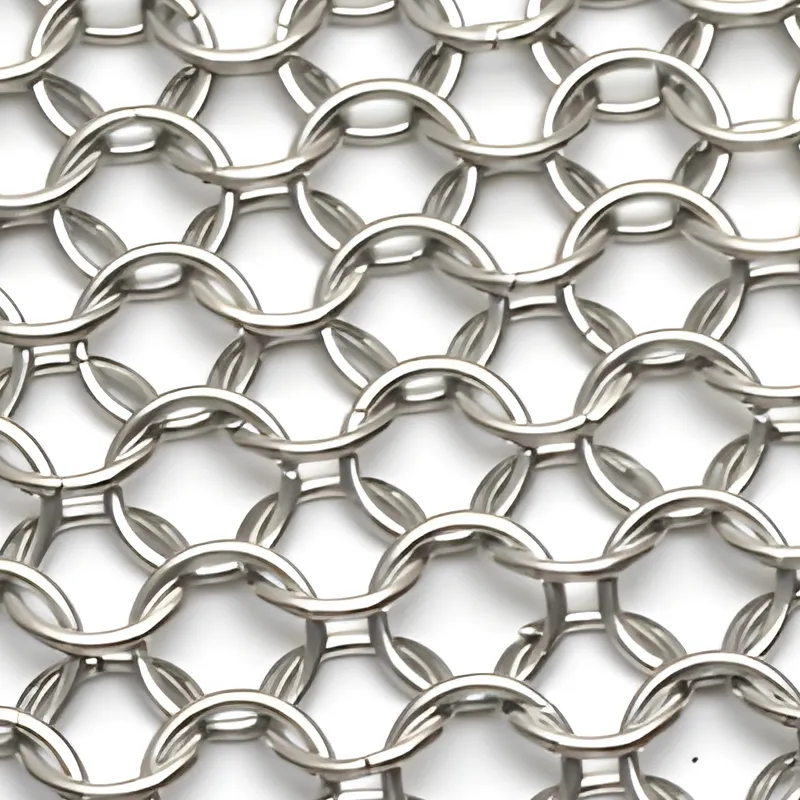

The global market for high-performance meshes is experiencing significant growth, driven by increasing industrialization, stringent environmental regulations, and a heightened focus on material longevity. Within this landscape, ss 316 mesh is increasingly recognized as a premium material, especially in sectors demanding superior corrosion resistance and hygiene. For instance, the pharmaceutical and food and beverage industries are adopting ss 316 wire mesh extensively for filtration and processing equipment due to its non-reactive nature and ease of sterilization, aligning with FDA and NSF standards. Similarly, the marine and offshore sectors heavily rely on 316 stainless steel for its exceptional resistance to chloride-induced corrosion, which is prevalent in saltwater environments. This upward trend is also observed in architectural and decorative applications, where the aesthetic appeal combined with the durability of ss steel mesh leads to innovative designs for building facades, interior partitions, and safety barriers, contributing to both functional and visual excellence.

Figure 1: Diverse applications of ss 316 mesh across industries.

Understanding the precise technical parameters is crucial for selecting the appropriate ss 316 mesh for any given application. Stainless steel 316 is an austenitic chromium-nickel stainless steel containing molybdenum, distinguishing it from 304 stainless steel by providing enhanced corrosion resistance, particularly against pitting and crevice corrosion in chloride environments. Key parameters include mesh count (or mesh per inch), wire diameter, aperture size, and open area percentage. The mesh count dictates the fineness of the mesh, affecting filtration efficiency, while wire diameter influences mechanical strength and durability. Aperture size directly relates to the maximum particle size that can pass through the mesh, and open area percentage affects flow rates and light transmission for ss mesh for windows. Typical specifications adhere to international standards such as ASTM E2016 for industrial woven wire cloth, ensuring consistency and quality. The tensile strength of 316 stainless steel generally ranges from 515-690 MPa, with a yield strength of 205-310 MPa, offering robust performance under stress. Its resistance to elevated temperatures, with an oxidation resistance up to 870°C intermittently and 925°C continuously, further broadens its operational envelope, making it ideal for high-temperature filtration or heat exchangers. This combination of corrosion resistance, strength, and thermal stability makes ss steel net an indispensable material in challenging industrial environments where lesser materials would quickly degrade.

Common ss 316 mesh Specification Table

| Parameter | Typical Range/Value | Description/Benefit |

|---|---|---|

| Mesh Count | 2 to 500 Mesh/inch | Controls particle size filtration; higher count for finer filtration. |

| Wire Diameter | 0.02mm to 4.0mm | Influences mesh strength and open area. |

| Aperture Size | 0.026mm to 12.7mm | The clear opening between wires, critical for filtration and screening. |

| Open Area | 20% to 90% | Affects flow rate, light penetration, and material strength. |

| Corrosion Resistance | Excellent in Chloride Environments | Due to Molybdenum content, superior to 304 SS. |

| Temperature Range | Up to 870°C (1598°F) | Suitable for high-temperature applications. |

The Advanced Manufacturing Process of ss 316 Wire Mesh

The production of high-quality ss 316 wire mesh is a sophisticated process that begins with the meticulous selection of raw materials. Only premium-grade 316 or 316L stainless steel billets, conforming to international standards like ASTM A276 or EN 10088, are utilized. The "L" variant (316L) signifies a lower carbon content, which is crucial for enhanced weldability and reduced carbide precipitation, preventing intergranular corrosion, especially in welded components that will operate in corrosive environments. The manufacturing journey typically involves several critical stages, each rigorously controlled to ensure the final product’s integrity and performance. The process starts with wire drawing, where the raw stainless steel rods are drawn through a series of dies to achieve the desired wire diameter. This step requires precision machinery to ensure uniform wire gauge and surface finish, critical for consistent mesh characteristics. Following this, the wires undergo annealing to relieve internal stresses and improve ductility, making them suitable for weaving or welding.

Figure 2: Precision weaving machines for ss 316 wire mesh.

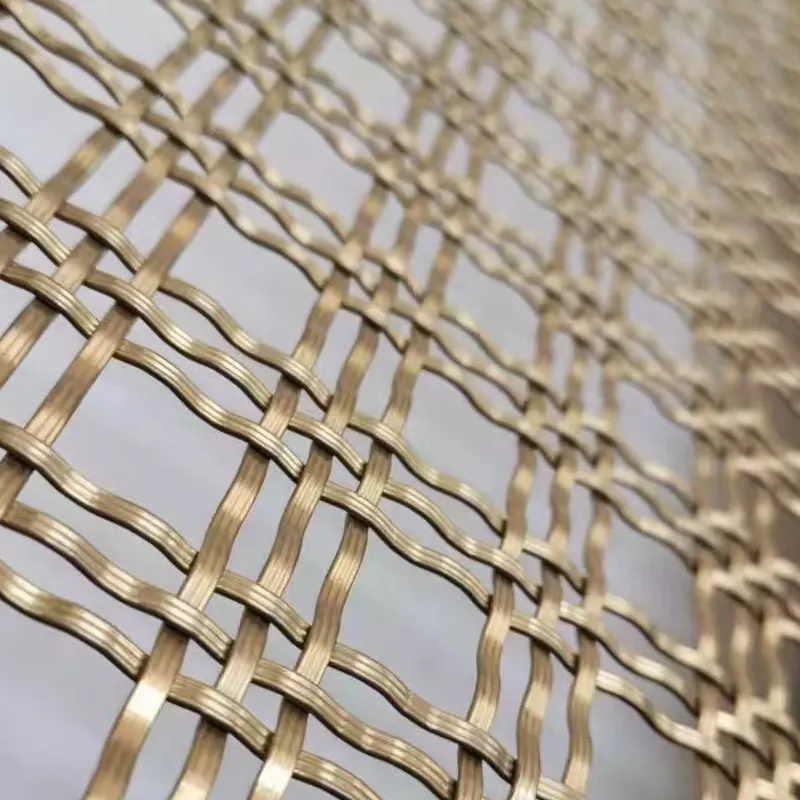

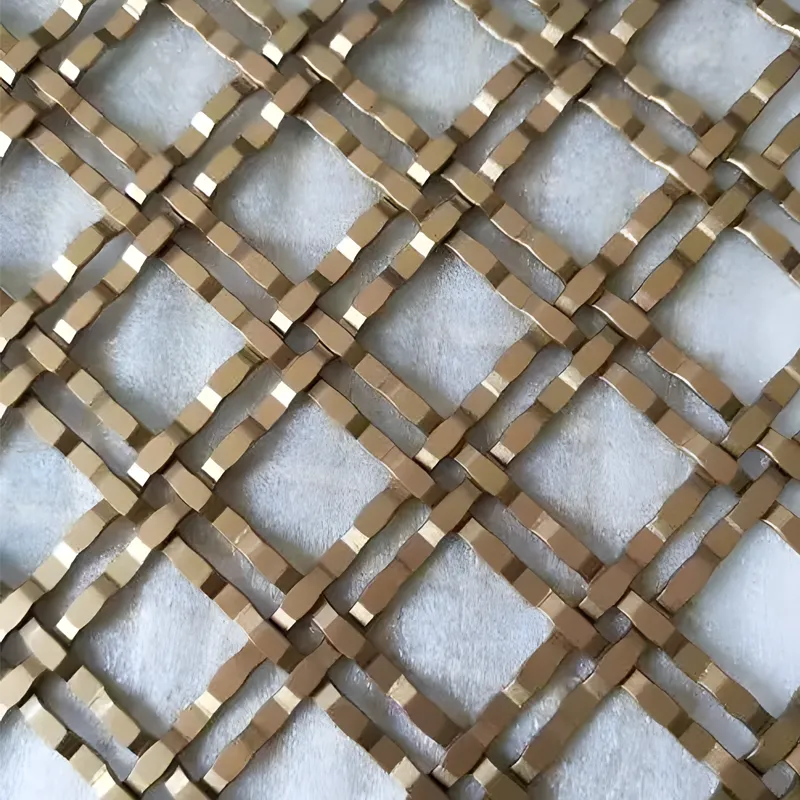

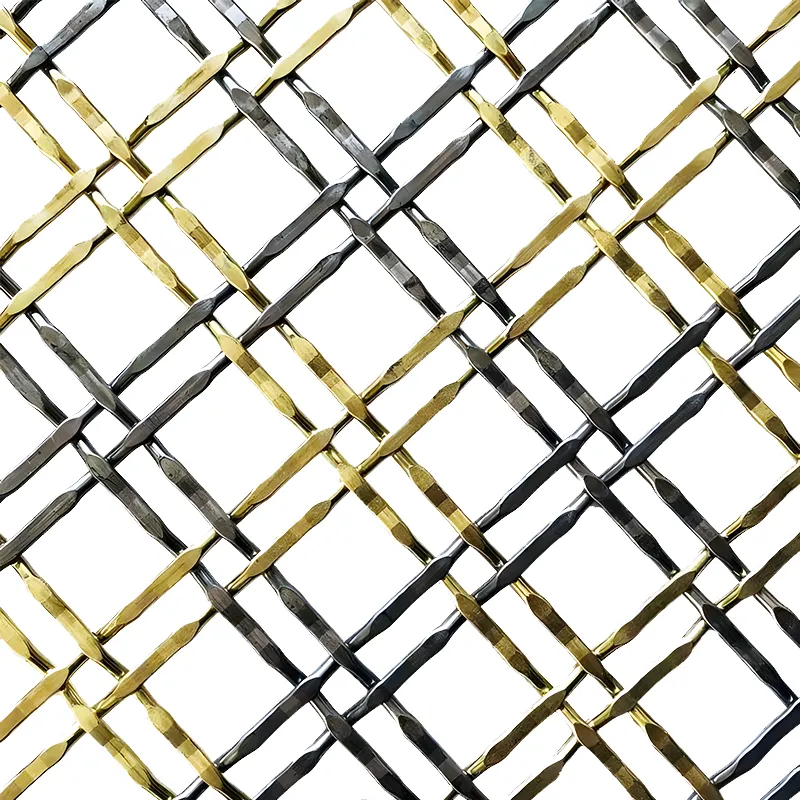

The primary fabrication methods for ss 316 mesh are weaving and welding. Woven mesh is produced on specialized looms, where warp and weft wires are interlaced in various patterns—plain weave, twill weave, and Dutch weave being the most common. Plain weave offers good stability and versatility, while twill weave provides higher strength and finer filtration. Dutch weave, with its unique tightly packed warp wires, is ideal for very fine filtration and high-pressure applications. Welded ss steel mesh is manufactured by resistance welding intersecting wires at precise intervals, creating a strong, rigid structure often used in heavier-duty applications like security screens or reinforcement. Post-fabrication, surface treatments such as passivation or electropolishing are applied to enhance corrosion resistance by removing free iron from the surface and creating a passive oxide layer, and to improve cleanliness, which is particularly vital for applications in the food, beverage, and pharmaceutical industries where hygiene standards are non-negotiable.

Figure 3: Rigorous quality control measures ensuring mesh integrity.

Throughout the entire manufacturing process, stringent quality control measures are implemented. This includes continuous monitoring of wire dimensions, mesh count verification using optical comparators, and comprehensive material composition analysis using X-ray fluorescence (XRF) or atomic emission spectroscopy to confirm the 316 alloy composition. Mechanical testing, such as tensile strength and elongation tests, is also conducted to ensure the mesh meets specified structural requirements. Adherence to international quality management systems like ISO 9001 and industry-specific standards (e.g., ANSI for filter elements) is paramount, guaranteeing that every batch of ss 316 mesh meets the highest standards for performance, reliability, and longevity. The anticipated service life of a well-maintained ss 316 mesh in appropriate applications can extend for decades, minimizing replacement costs and downtime. This robust manufacturing protocol ensures that the final product is not only compliant but also optimized for durability and efficiency in its intended industrial environment.

Key Applications and Technical Advantages of ss 316 Mesh

The unparalleled attributes of ss 316 mesh make it indispensable across a multitude of high-stakes industrial applications. In the petrochemical and chemical processing industries, its superior resistance to a wide range of corrosive media, including sulfuric acid, hydrochloric acid, and chlorides, makes it ideal for filtration units, catalyst support grids, and protective screens. This significantly reduces equipment downtime due to material degradation, leading to substantial operational cost savings and enhanced safety. For instance, in crude oil refining, ss 316 mesh is crucial for effective separation in distillation columns and for filtering impurities in various process streams. Similarly, in pharmaceutical manufacturing, where sterile environments and non-contamination are critical, ss 316 wire mesh is extensively used for drying trays, sieve screens, and filter components, ensuring product purity and compliance with cGMP (current Good Manufacturing Practices) regulations.

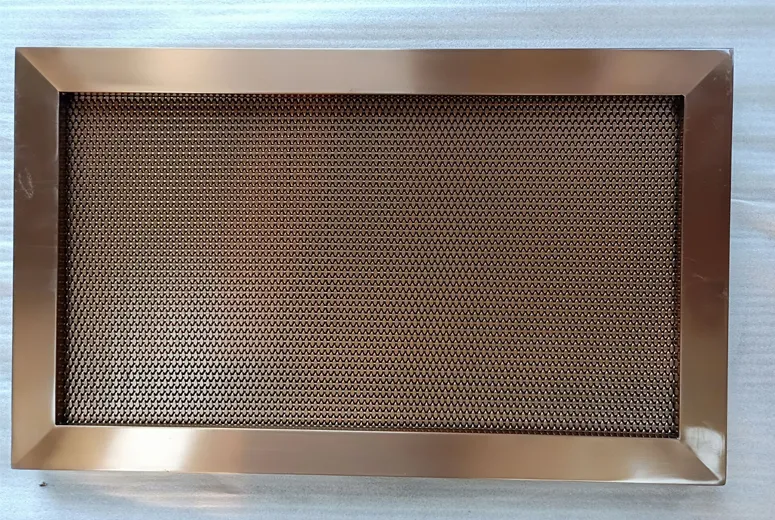

Figure 4: Aesthetic and functional use of ss mesh for windows in modern architecture.

Beyond industrial processing, ss mesh for windows and general architectural applications leverage the material's aesthetic appeal, structural integrity, and resistance to environmental elements. It provides excellent ventilation, insect protection, and security, all while maintaining a sleek, modern appearance that integrates seamlessly with contemporary building designs. In marine environments, from desalination plants to offshore platforms, ss 316 mesh is vital for seawater intake screens, ballast water treatment systems, and protective barriers against biofouling due to its specific resistance to chloride attack, a common failure mode for lesser alloys. The material's longevity and minimal maintenance requirements translate into lower lifecycle costs for these demanding applications. Furthermore, in power generation, particularly in cooling towers and heat exchangers, the excellent corrosion and temperature resistance of ss steel mesh contribute to energy efficiency by maintaining optimal flow dynamics and heat transfer rates without succumbing to scaling or corrosion, thereby extending the operational lifespan of critical infrastructure and reducing the frequency of costly shutdowns for repairs or replacements.

Figure 5: ss steel net deployed in heavy industrial settings.

Technically, the advantages of ss 316 mesh stem from its specific chemical composition: typically 16-18% Chromium, 10-14% Nickel, and crucially, 2-3% Molybdenum. Molybdenum is the key alloying element that significantly enhances its resistance to localized corrosion mechanisms such as pitting and crevice corrosion, which are common in environments containing chlorides (e.g., seawater, brine solutions, certain chemical process streams). This superior corrosion resistance translates directly into an extended service life and reduced maintenance, offering a far more economical long-term solution compared to less resilient materials that would require frequent replacement. Moreover, 316 stainless steel exhibits excellent mechanical properties at both elevated and cryogenic temperatures, maintaining ductility and strength over a broad operational range. Its non-magnetic properties (in its annealed condition) also make it suitable for applications where magnetic interference must be avoided. The ease of cleaning and sanitation, coupled with its hygienic properties, further solidifies its position as a preferred material in sensitive industries. Its robust construction ensures stability and integrity, even under demanding operational pressures or environmental stresses, contributing to overall system reliability and optimal performance in critical infrastructure. The inherent energy-saving potential of filter media constructed from ss 316 mesh comes from its consistent pore size and high open area, which lead to lower pressure drops and thus reduced energy consumption for fluid processing applications.

Choosing Your Partner: Manufacturer Comparison and Customization with ss 316 mesh

Selecting the right manufacturer for your ss 316 mesh requirements is as critical as the material choice itself. A reputable supplier should demonstrate a proven track record, adherence to international quality standards, and robust technical capabilities. Key factors to consider during vendor evaluation include ISO 9001 certification, which signifies a commitment to quality management systems; extensive experience in producing stainless steel mesh for diverse industries; and the capacity for customization. For example, a manufacturer's ability to supply ss 316 wire mesh in various weave patterns (plain, twill, Dutch), specific mesh counts, and custom dimensions is crucial for specialized applications. Furthermore, evaluating their in-house testing facilities for material composition (e.g., spectrometer analysis), tensile strength, and corrosion resistance helps verify product quality. Transparency in their supply chain, including the origin and certification of raw 316 stainless steel, adds another layer of trust. A reliable partner will also offer comprehensive technical support, guiding you through material selection, design optimization, and installation best practices. They should be able to provide detailed product specifications, material safety data sheets, and compliance certificates for relevant industry standards such as ASTM or DIN.

Figure 6: Custom-designed ss 316 mesh solutions for specific industrial needs.

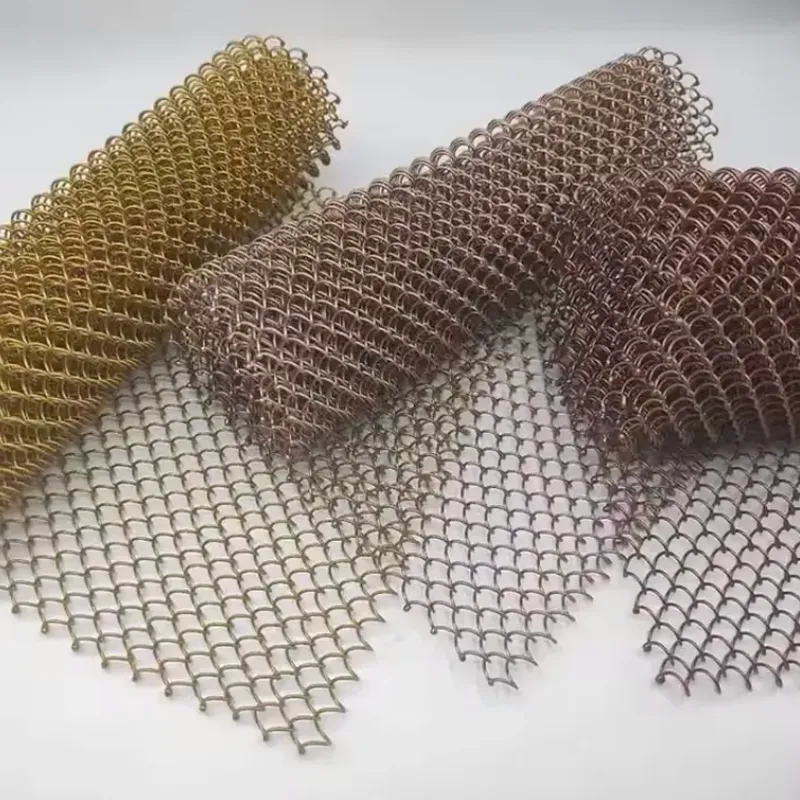

Customization is a cornerstone of effective ss 316 mesh solutions, especially for complex industrial systems. While standard sizes and specifications are available, many applications require bespoke designs to optimize performance and integration. This could involve unique mesh configurations for specific filtration efficiencies, specialized edge treatments for improved installation and safety, or custom fabrication into filter elements, baskets, or architectural panels. For example, in the production of Metal Decorative Mesh, specific wire crimping or weaving patterns might be required to achieve a desired aesthetic or light diffusion property. The ability to tailor the mesh to precise pore sizes, open areas, and mechanical strength ensures optimal flow rates, particle retention, and structural integrity. A comprehensive customization process typically begins with an in-depth consultation, where the client's specific operational parameters, environmental conditions, and performance expectations are thoroughly discussed. Based on this, technical experts can recommend the ideal wire diameter, mesh count, weave type, and post-processing treatments (e.g., electropolishing for pharmaceutical use, or powder coating for architectural aesthetics). This collaborative approach ensures that the final ss 316 mesh product is perfectly aligned with the application's unique demands, maximizing efficiency and minimizing potential issues. Experienced manufacturers will also offer prototyping services to validate the design before full-scale production, ensuring that all specifications are met with precision and reliability.

Figure 7: Advanced fabrication techniques for custom ss steel mesh components.

Leading manufacturers of ss 316 mesh distinguish themselves through their rigorous quality assurance protocols and commitment to customer support throughout the entire project lifecycle. This includes providing detailed technical drawings, conducting pre-shipment inspections, and offering post-sales service and maintenance advice. The focus is not merely on selling a product, but on delivering a complete solution that integrates seamlessly into the client's operations. The partnership extends beyond the initial purchase, with ongoing technical consultation, troubleshooting support, and the provision of replacement parts as needed. For large-scale industrial projects, manufacturers often offer project management services, coordinating production schedules with client timelines to ensure on-time delivery. This holistic approach, encompassing material expertise, precision manufacturing, extensive customization capabilities, and dedicated technical support, is what truly sets a world-class ss 316 mesh supplier apart, ensuring optimal performance and long-term value for clients in demanding industrial sectors. Companies with a long service history, like those with decades in the industry, often have the depth of knowledge and experience to tackle even the most complex mesh challenges, providing a tangible advantage in terms of reliability and innovation.

Application Cases and Client Success with ss 316 Mesh

The real-world efficacy of ss 316 mesh is best illustrated through its successful deployment in critical applications across diverse industries. For example, a leading municipal wastewater treatment plant faced persistent issues with corrosion and frequent replacement of carbon steel screens in its primary filtration units. By replacing these with custom-fabricated ss 316 wire mesh screens, they achieved a remarkable 70% reduction in maintenance costs over five years and significantly improved effluent quality due to the mesh's consistent filtration capabilities and resistance to biological fouling. This not only extended the operational lifespan of their filtration system but also enhanced the plant's overall environmental compliance. In another instance, a major offshore oil and gas platform struggled with premature failure of filter elements in its produced water treatment system due to the highly corrosive nature of the saline water and entrained hydrocarbons. The adoption of specialized ss 316 mesh filter cartridges, designed for enhanced chemical resistance and structural integrity, extended filter lifespan by 300%, drastically reducing change-out frequencies and associated operational expenditures in a remote and challenging environment.

Figure 8: ss 316 mesh optimizing performance in advanced filtration systems.

Client feedback consistently highlights the superior performance and long-term value offered by ss 316 mesh. A major pharmaceutical company reported that switching to ss 316 mesh drying trays for their active pharmaceutical ingredients (APIs) not only eliminated contamination risks from rusting surfaces but also improved drying efficiency due to the mesh's smooth surface and consistent aperture, leading to faster processing times and higher product yields. Testimonials often underscore the material's reliability in preventing operational disruptions. One client from the food processing industry stated, "Since integrating ss 316 mesh into our critical filtration stages, we've seen a measurable improvement in product purity and a significant reduction in our filter replacement schedule, directly translating to enhanced profitability and consistent product quality." These real-world successes underscore the economic advantages, environmental benefits, and operational efficiencies that stem from investing in high-quality ss 316 mesh solutions.

Figure 9: ss steel net enhancing the aesthetic and safety of modern architectural designs.

These cases exemplify how strategic investment in high-grade materials like ss 316 mesh can address complex industrial challenges, leading to measurable improvements in operational performance, cost savings, and regulatory compliance. The versatility of ss 316 mesh extends to architectural applications as well, where clients report enhanced building aesthetics, improved natural light penetration when used as facade elements, and superior long-term durability in outdoor conditions compared to other decorative materials. For instance, an architect specified Metal Decorative Mesh made from 316 stainless steel for a coastal museum's exterior cladding. The decision was driven by the material's exceptional resistance to salt spray corrosion and its ability to maintain its lustrous appearance over decades without significant maintenance, thereby reducing the building's lifecycle costs and preserving its visual appeal against harsh marine elements. These compelling examples serve as strong evidence of the material's reliability and its capacity to deliver tangible benefits, justifying its position as a preferred choice for discerning industrial and architectural applications. The proven track record of ss 316 mesh in such diverse and demanding environments reinforces its status as a premium, high-performance solution.

Frequently Asked Questions (FAQ) about ss 316 Mesh

Q1: What is the primary advantage of ss 316 mesh over 304 stainless steel mesh?

A1: The key advantage of ss 316 mesh lies in its superior corrosion resistance, particularly against pitting and crevice corrosion in chloride-rich environments. This is due to the addition of 2-3% Molybdenum in its alloy composition. While 304 SS performs well in general corrosive conditions, 316 SS is specifically engineered for harsher environments like marine applications, chemical processing, and pharmaceutical industries where exposure to salts, acids, or other aggressive chemicals is common. This significantly extends its service life and reduces maintenance needs in such challenging settings.

Q2: What is the typical service life of ss 316 mesh?

A2: The service life of ss 316 mesh is highly dependent on the specific application, environmental conditions, and maintenance practices. However, owing to its exceptional corrosion and temperature resistance, properly selected and installed ss 316 mesh can last for several decades, often exceeding 20-30 years in non-extreme environments. In highly corrosive or abrasive industrial settings, its lifespan will still significantly outperform lesser materials, offering long-term cost-effectiveness and reliability. Regular inspection and appropriate cleaning can further extend its operational life.

Q3: Can ss 316 mesh be customized for specific industrial filtration needs?

A3: Absolutely. Customization is a core offering for ss 316 mesh. Manufacturers can tailor the mesh to precise specifications, including varying mesh counts (from coarse to extremely fine, e.g., 2 mesh to 500 mesh), wire diameters, aperture sizes, and weave patterns (plain, twill, Dutch weave) to meet exact filtration efficiency, flow rate, and strength requirements. Furthermore, it can be fabricated into diverse forms such as filter cartridges, screens, baskets, discs, and architectural panels, often with custom finishes like electropolishing for sanitary applications or specialized coatings for aesthetic purposes, ensuring optimal performance for the intended application.

Q4: What quality certifications should I look for when sourcing ss 316 mesh?

A4: When sourcing ss 316 mesh, prioritize manufacturers with ISO 9001 certification, which confirms a robust quality management system. For material specifications, adherence to ASTM (American Society for Testing and Materials) standards such as ASTM E2016 for woven wire cloth, or ASTM A240 for stainless steel plate, sheet, and strip, is crucial. For applications in food, beverage, or pharmaceutical industries, compliance with FDA (Food and Drug Administration) or NSF (National Sanitation Foundation) guidelines for material safety and hygiene is paramount. A reputable supplier will readily provide material test certificates (MTCs) confirming the chemical composition and mechanical properties of the 316 stainless steel used.

Q5: What is the typical delivery lead time for ss 316 mesh orders?

A5: Delivery lead times for ss 316 mesh can vary based on the order volume, level of customization, and current production schedules. For standard mesh specifications and quantities, lead times typically range from 2 to 4 weeks. However, for highly customized orders, large volumes, or specialized fabrication, it might extend to 6-10 weeks. It is always recommended to discuss specific lead times with the manufacturer during the quotation phase, and a reliable supplier will provide transparent and realistic timelines. Expedited options may be available for urgent requirements, though these often incur additional costs. Many manufacturers also offer buffer stock for high-volume or recurring orders to ensure just-in-time delivery.

Figure 10: Adherence to stringent quality assurance protocols for ss 316 mesh.

Commitment to Quality & Service Excellence

Our commitment extends beyond simply manufacturing ss 316 mesh; we aim to be a comprehensive partner in your industrial success. We understand that timely delivery is critical to maintaining your project timelines and operational efficiency. Therefore, we streamline our production processes and logistics to ensure efficient order fulfillment, providing clear delivery schedules and responsive communication throughout the shipping process. Each batch of ss 316 mesh undergoes rigorous quality assurance protocols, from raw material inspection to final product verification. This includes comprehensive chemical composition analysis, mechanical property testing (tensile strength, elongation), and detailed dimensional checks to ensure precise adherence to specified mesh count, wire diameter, and aperture size. Our products meet or exceed international standards such as ISO 9001, ASTM E2016, and relevant industry-specific certifications, ensuring consistent quality and reliability.

We stand behind the quality of our ss 316 mesh with robust warranty commitments, protecting your investment and providing peace of mind. Our dedicated customer support team is available to assist with technical queries, product selection, installation guidance, and any post-sales support you may require. We pride ourselves on building lasting relationships with our clients by offering expert consultation and a seamless service experience, ensuring that your ss 316 mesh solutions contribute effectively to your operational goals. Whether it's a standard order or a complex custom fabrication, our team is equipped with the expertise and resources to deliver high-performance, durable solutions that address the unique challenges of your industry. Our commitment to continuous improvement means we invest in advanced manufacturing technologies and ongoing staff training to maintain our position at the forefront of stainless steel mesh innovation and service excellence.

References

- Davis, J. R. (2001). Stainless Steels. ASM International.

- Frankel, G. S. (2012). Pitting and Crevice Corrosion. Corrosion Science, 54, 1-27.

- ASTM International. (2020). ASTM E2016-11(2020) Standard Specification for Industrial Woven Wire Cloth.

- ISO. (2018). ISO 9001:2015 Quality management systems — Requirements.

- Sedriks, A. J. (1996). Corrosion of Stainless Steels. John Wiley & Sons.