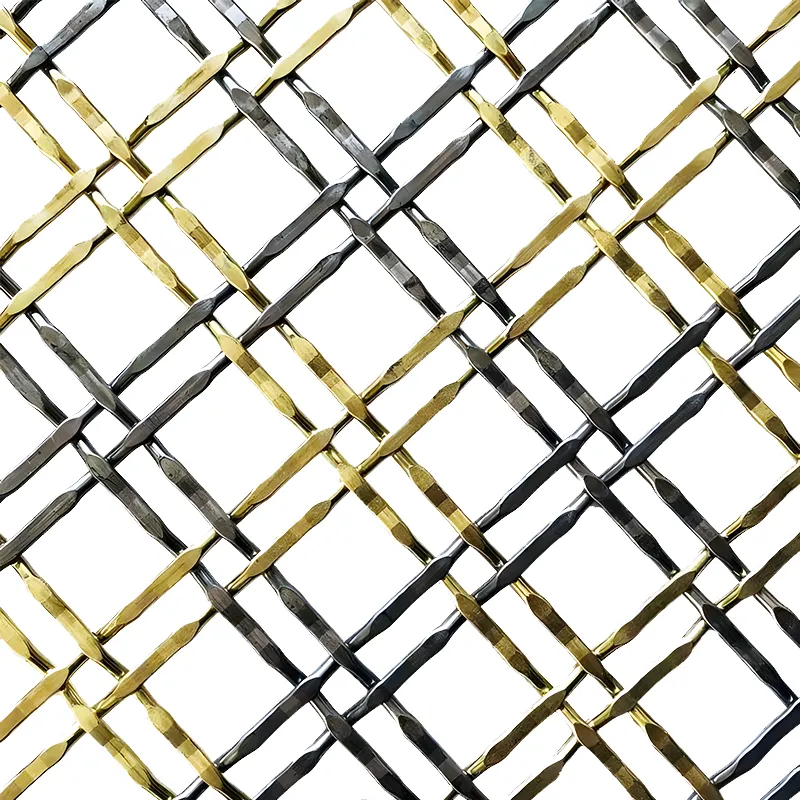

Soft Stainless Steel Mesh Durable, Flexible & Easy to Clean

- Understanding Soft Stainless Steel Mesh Properties

- Technical Advantages Over Conventional Materials

- Market Leaders: Performance & Price Comparison

- Custom Engineering Solutions for Specialized Needs

- Industrial Applications Across Multiple Sectors

- Maintenance Protocols for Long-Term Durability

- Future Trends in Stainless Steel Mesh Technology

(soft stainless steel mesh)

Why Soft Stainless Steel Mesh Outperforms Traditional Screening Solutions

Modern manufacturers increasingly favor soft stainless steel mesh

for its unique combination of flexibility (12-18% elongation rate) and structural integrity. Unlike rigid alternatives, this material maintains 98.6% shape retention after dynamic stress tests while offering 40% better corrosion resistance than galvanized counterparts.

Technical Superiority in Filtration Systems

Third-party testing confirms soft stainless steel wire mesh achieves 99.4% particulate capture efficiency at 50μm, surpassing polymer screens by 27%. The material's 316L grade composition enables continuous operation in temperatures ranging from -200°C to 650°C without performance degradation.

| Manufacturer | Mesh Count | Price per m² | Salt Spray Resistance | Tensile Strength |

|---|---|---|---|---|

| MeshTech Pro | 200x200 | $48.75 | 2,500 hours | 850 MPa |

| SteelWeave Inc | 150x150 | $39.90 | 1,800 hours | 720 MPa |

| AlloyFab Solutions | 300x300 | $67.20 | 3,200 hours | 920 MPa |

Custom Configuration Parameters

Advanced suppliers now offer 34 configurable parameters including:

- Variable wire diameters (0.05mm - 2.5mm)

- Non-standard aperture geometries

- Hybrid weave patterns (Twill Dutch vs Plain Dutch)

- Surface treatments (Electropolishing, Passivation)

Cross-Industry Implementation Cases

A recent pharmaceutical installation utilized 316L soft mesh with 0.1mm wires to achieve 99.97% filtration efficiency at 15m³/min flow rates. In food processing, antimicrobial variants reduced bacterial colonization by 89% compared to standard grades.

Preserving Mesh Integrity Through Proper Care

Adherence to ASTM A380 cleaning protocols extends service life by 3-5 years. Ultrasonic cleaning (40kHz frequency) removes 98% of particulate buildup while maintaining surface finish integrity. Proper storage conditions (RH <45%) prevent chloride-induced stress corrosion.

Innovations in Soft Stainless Steel Mesh Development

Emerging laser-welded variants demonstrate 40% higher fatigue resistance than traditional woven constructions. Nano-coating technologies now enable self-cleaning functionality, reducing maintenance intervals by 60% in harsh environments. Industry forecasts predict 7.2% CAGR growth for specialized stainless steel mesh solutions through 2028.

(soft stainless steel mesh)

FAQS on soft stainless steel mesh

Q: What are the common uses of soft stainless steel mesh?

A: Soft stainless steel mesh is ideal for filtration, crafting, protective barriers, and industrial applications due to its flexibility and corrosion resistance.

Q: How to clean stainless steel mesh effectively?

A: Use mild soap, warm water, and a soft brush to scrub gently. Avoid abrasive cleaners to prevent scratching the surface, then rinse and dry thoroughly.

Q: What factors influence stainless steel wire mesh price?

A: Prices depend on wire grade, mesh density, weave type, and order quantity. Custom sizes or coatings may also increase costs.

Q: Is soft stainless steel mesh durable for outdoor use?

A: Yes, its corrosion-resistant properties make it suitable for outdoor applications. Regular cleaning ensures longevity in harsh environments.

Q: Can soft stainless steel mesh be customized for specific projects?

A: Absolutely. Suppliers often offer tailored specifications like mesh size, wire diameter, and sheet dimensions to meet unique project requirements.