Premium Stainless Steel Expanded Sheets | Durable & Lightweight

The stainless steel expanded sheet stands at the frontier of filtration, architecture, and advanced industrial design. As industries increasingly demand decorative aluminum mesh and decorative expanded metal mesh for both functionality and aesthetics, this versatile material answers with robust properties, eco-efficiency, and virtually limitless design possibilities.

1. Market Trends & Industry Perspective

According to the latest report from Market Research Future, the global expanded metal market is projected to grow at a CAGR of 4.75% through 2030, fueled by construction, energy, water treatment, petrochemical, and automotive applications. Stainless steel expanded sheet is at the core of this growth, enabling energy-efficient, corrosion-resistant, and customizable filtering and decorative solutions.

Applications in Key Sectors

- Petrochemical: Reliable filtration and separation solutions for oil, gas, and chemicals.

- Metallurgy: High-temperature resistance for segregating particulates and protecting installations.

- Water Treatment: Corrosion-resistance for membrane supports and debris filters.

- Construction & Architecture: Facades, cladding, sunscreens, and ventilation panels (leveraging both decorative aluminum mesh and decorative expanded metal mesh).

- Automotive: Custom air intake grilles, safety shields, and reinforcement.

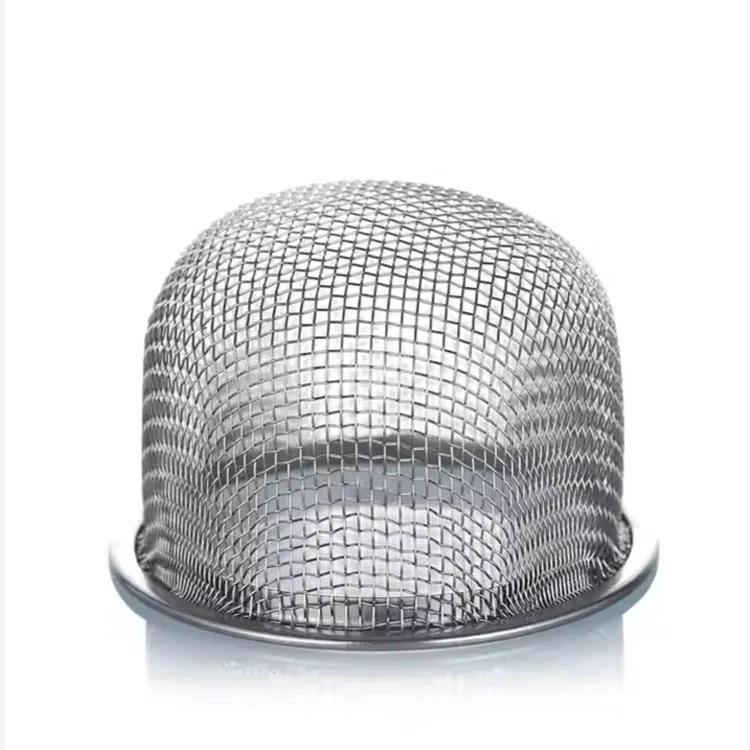

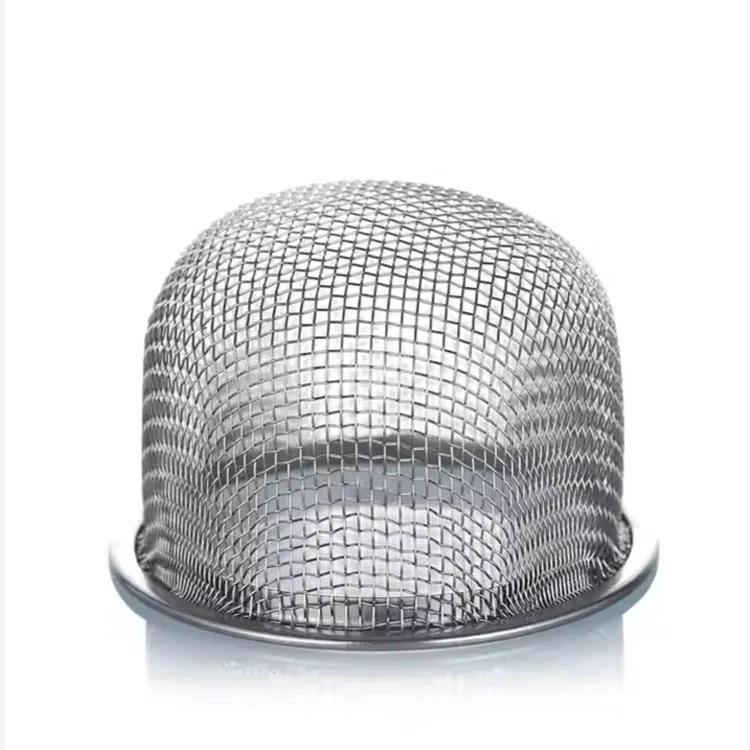

- Filtration Devices: Core material for Bowl Filter Screens.

2. Technical Parameters & Product Comparison

Main Parameters of Stainless Steel Expanded Sheet

| Parameter | Typical Value/Options | Industry Standard |

|---|---|---|

| Material Grade | SS304, SS316, SS316L | ASTM A240 / ISO 9001 |

| Thickness (mm) | 0.3 – 6.0 | ASTM E2016 |

| SWD / LWD (mm) | 6×12, 8×16, 20×30, custom | ISO 7808:2002 |

| Strand Width (mm) | 0.5 – 3.0 | Customer spec |

| Open Area (%) | 45 – 85% | ISO 9013:2002 |

| Surface Finish | Mill, Anodized, Powder-coated | ASTM A967 |

| Certification | ISO, FDA, SGS, RoHS | Compulsory for filtration |

Key Highlight: For Bowl Filter Screens, primary choices are usually SS304/316L with strand width 0.9–1.2 mm and open area 54–75% for optimal flow and strength.

Bowl Filter Screens Technical Comparison

3. Manufacturing Process—From Raw Sheet to Advanced Filter Screen

1. Raw Material Selection: High-quality stainless steel expanded sheet begins with SS304/316/316L coils, certified per ISO 9001 for composition, surface finish, and mechanical integrity.

→

1. Raw Material Selection: High-quality stainless steel expanded sheet begins with SS304/316/316L coils, certified per ISO 9001 for composition, surface finish, and mechanical integrity.

→

2. Expanding & Slitting: Sheets are simultaneously slit and stretched via CNC press technology, ensuring consistent strand width and opening pattern per ASTM E2016.

→

2. Expanding & Slitting: Sheets are simultaneously slit and stretched via CNC press technology, ensuring consistent strand width and opening pattern per ASTM E2016.

→

3. Forming & Shaping: Custom molds, rolling, and laser cutting shape the mesh into cylinder or bowl forms, as required by Bowl Filter Screens. Precise dimensional tolerances ensured by ANSI/ISO protocols.

→

3. Forming & Shaping: Custom molds, rolling, and laser cutting shape the mesh into cylinder or bowl forms, as required by Bowl Filter Screens. Precise dimensional tolerances ensured by ANSI/ISO protocols.

→

4. Surface Treatment: Degreasing, passivation, and—where specified—anodizing or powder coating to enhance corrosion resistance; all compliant with ASTM A967 and FDA requirements.

→

4. Surface Treatment: Degreasing, passivation, and—where specified—anodizing or powder coating to enhance corrosion resistance; all compliant with ASTM A967 and FDA requirements.

→

5. Final Inspection & Testing: Dimensional, mechanical strength, and flow performance tests per ISO 9001. Batch traceability, documentation, and physical marking.

5. Final Inspection & Testing: Dimensional, mechanical strength, and flow performance tests per ISO 9001. Batch traceability, documentation, and physical marking.

Click to watch: How Stainless Steel Expanded Sheet is Made

4. Technical Advantages: Why Choose Stainless Steel Expanded Sheet?

- Superior Corrosion Resistance: Stainless alloys withstand harsh chemicals and water—optimal for filtration, water treatment, and outdoor architectural mesh.

- High Mechanical Strength: Expanded structure increases rigidity without significant weight addition; strand and bond configuration resists deformation under load.

- Controlled Open Area: Fine-tuned mesh geometry ensures balance between filtration efficiency and maximum fluid/gas flow rate.

- Eco-Friendly Production: Waste-free expansion process maximizes material utilization; recyclability of stainless steel reduces lifecycle footprint (Stainless Steel World).

- Design Versatility: Broad range of decorative and industrial patterns possible, supporting custom branding (especially in decorative aluminum mesh solutions).

- Long Service Life: Typical life 10–15 years, minimizing replacement and downtime in critical industry applications.

5. Manufacturer Comparison & Customization Solutions

| Company | Main Region | Certifications | Custom Capability | MOQ |

|---|---|---|---|---|

| QH Filter | China/Global | ISO 9001, FDA, SGS | Any shape/size (OEM/ODM) | 10 pcs |

| Metalex | USA | ISO 9001, RoHS | Standard/patterns | 50 pcs |

| RMIG | EU | ISO 14001, CE | Architectural only | 30 sqm |

| Ferrofab | Dubai/MENA | ISO 45001, SGS | Medium | 100 pcs |

Custom Engineering Solutions

- Custom mesh geometry (SWD/LWD) and filtration rating per client flow/solids requirements

- Precision-forming: cylinders, bowls, discs, cones—with laser-cut edges for Bowl Filter Screens

- Value-added: double-layer, reinforced rib, or composite mesh for heavy-duty filtration

- Optional surface color/anodizing for architectural/decorative expanded metal mesh

- Batch-traceable 3.1B material certificate, cleanroom packaging, and global logistic support

6. Typical Application Scenarios & Engineering Cases

Petrochemical Filtration: High Corrosion & Pressure Demands

Case: In a major Middle East refinery, QH Filter’s stainless steel expanded sheet Bowl Filter Screens replaced perforated plate elements due to higher dirt-holding and proven longer lifespan (12,300 hours vs. 8,200 hours, per API 614 report). View details

Water Treatment: Wastewater & Desalination Plants

Large-diameter decorative expanded metal mesh screens are deployed in tertiary filtration before membrane systems. Analysis from Engineering360 suggests a 27% reduction in membrane fouling events with expanded mesh support.

Construction & Facade Engineering

2023 Spotlight: A Shanghai landmark office tower installed 2300 sqm of custom anodized decorative aluminum mesh panels, reporting a 14% reduction in HVAC load due to optimized airflow and shading properties in the mesh specification.

Food & Pharma Filtration

Bowl Filter Screens with FDA food-grade stainless support ensure zero leaching, per FDA CFR 177.2600; widely used in brewery and biopharma CIP skids.

HVAC & Automotive: Airflow & Durability

Custom-formed stainless steel expanded sheet grilles provide impact protection and airflow in industrial AC units and automotive intake modules; lab tests confirm static pressure loss decreased by up to 18% over stamped-perforated counterparts.

7. Bowl Filter Screens — Specification Pie Chart

8. Service, Delivery, and Warranty Information

| Service Item | Details |

|---|---|

| Delivery Time | Standard: 7–10 working days; Rush: 3–5 days (stock items); Custom: 11–18 days |

| Quality Assurance | 12-month warranty; 100% replacement for confirmed defects; batch test certs supplied |

| Technical Support | 24/7 engineering hotline; installation and sizing consultation; sample approval service |

| Traceability & Docs | Full 3.1B certificate, ISO/FDA documentation upon request |

9. FAQ: Technical & Application FAQ

A: Standard diamond pattern with 6×12 mm SWD/LWD and 0.9–1.2 mm strand width, achieving 55–75% open area for balanced flow and support.

A: Primary standards: ASTM E2016 (expanded metal specification), ISO 9001 (quality management), ASTM A240 (material spec), FDA CFR 177.2600 (food contact), SGS/RoHS (environmental compliance).

A: Aluminum mesh prioritizes lightweight and corrosion-resistance for facades/ceilings but lower mechanical strength; stainless steel is superior in structural rigidity, lifespan, and high-pressure filtration.

A: Dimensional inspection, salt spray test (>48h/120h per ASTM B117), burst/hydrostatic strength, digital mesh/photo verification, 3rd-party analysis as needed.

A: Yes—using modular CNC press and laser cutting, any diameter, height, or special bowl contour can be produced to customer’s supplied drawings.

A: Install with flow direction aligned to main strand; seal with EPDM or PTFE rings; ensure no mesh distortion during clamping for optimized sealing.

A: Professional powder-coating or anodizing (for aluminum) typically preserves—sometimes enhances—surface passivation, provided treatments follow ASTM/ISO guidelines.

10. Customer Experience & Global Certification

- 1000+ industrial installations worldwide

- Long-term collaborations: PetroChina, Linde, Sinopec, Veolia, and multiple leading EPC firms

- Product meets/exceeds ISO 9001:2015, ASME BPE, SGS, FDA contact requirements

- All Bowl Filter Screens batch-tested for flow, mechanical, and chemical resistance with traceable serials

11. Data Visualization: Service Life over Time

12. Conclusion & Further Resources

As stainless steel expanded sheet technology evolves with smarter designs, rigorous standards, and real-world reliability, it forms the backbone of safe, sustainable, and efficient filtration and architectural solutions. For industry professionals seeking proven, custom-engineered performance, Bowl Filter Screens exemplify this synergy—matchless durability, flow performance, and global quality compliance.

Interested to learn more or request technical consultation/sample? Contact QH Filter now.