Premium Stainless Steel Expanded Sheet | Durable Corrosion-Resistant

Bowl Filter Screens – Learn More

Industry Trends: The Growing Demand for Stainless Steel Expanded Sheet

The global stainless steel expanded sheet and decorative aluminum mesh market is witnessing robust growth due to their versatility, excellent corrosion resistance, and aesthetic appeal for architectural and industrial projects. Market research indicates a CAGR of 4.5% from 2021-2026, with Asia-Pacific leading in consumption (MarketsandMarkets).

Decorative expanded metal mesh is particularly in demand for modern architectural facades, safety partitions, and ventilation grilles. The increasing focus on sustainable, recyclable materials cements stainless steel expanded sheet as a preferred choice across infrastructure, petrochemicals, water treatment, and metallurgy industries.

Technical Parameters & Product Comparison

Stainless Steel Expanded Sheet offers a unique combination of strength, durability, and design adaptability. Here’s a quick reference chart comparing standard parameters for stainless steel expanded sheet and alternatives:

| Parameter | Stainless Steel Expanded Sheet | Decorative Aluminum Mesh | Decorative Expanded Metal Mesh |

|---|---|---|---|

| Material | SS304 / SS316L (per ISO 9001:2015) | Aluminum Alloy 1100/3003 | Carbon Steel, Aluminum, Stainless Steel |

| Standard Sheet Size (mm) | 1200×2400; 1000×2000 | 1200×2400 | 600×2400; 1000×2000 |

| Thickness (mm) | 0.5 – 6.0 | 0.5 – 2.5 | 0.4 – 5.0 |

| Strand (Width × Thickness, mm) | 0.45 × 0.50 up to 5.0 × 6.0 | 0.5 × 0.6 up to 2.0 × 2.5 | 0.7 × 1.0 up to 4.0 × 5.0 |

| Max. Open Area (%) | up to 75% | up to 79% | up to 77% |

| Corrosion Resistance | Excellent (chemical, saline, UV) | Good (less in acidic/alcaline) | Moderate–High (material dependent) |

| Certifications | ISO 9001 / ASTM F1267 | ASTM B209 | ISO, ASTM F1267, EN Standards |

Manufacturing Process of Stainless Steel Expanded Sheet

The manufacture of stainless steel expanded sheet is a precision-controlled sequence ensuring product uniformity and conformity to international standards like ISO 9001 and ANSI/ASTM. The major steps include:

- Material Selection: High-grade SS304, SS316L coils selected for corrosion resistance, tensile strength, and ductility.

- Cutting & Flattening: Sheets or coils are pre-cut per dimensional specifications, followed by straightening.

- Expanding: Using precision dies, sheets are simultaneously slit and stretched. The expansion creates diamond or hexagonal apertures; no material is wasted in this process, supporting sustainability goals.

- Leveling/Flattening: Expanded sheets pass through rollers to achieve uniform thickness and flatness as per EN 10346 standard.

- CNC Finishing: Sheets may undergo edge trimming, surface smoothing, or custom patterning with CNC routers.

- Inspection & Testing: Dimensional, mechanical, and surface checks (involving Salt Spray, Tensile Tests, and Ultrasonic Defect Tests in compliance with ISO 6892-1).

- Packing & Traceability: Every bundle labeled per batch, including full traceability chain.

💻 Manufacturing Workflow Diagram

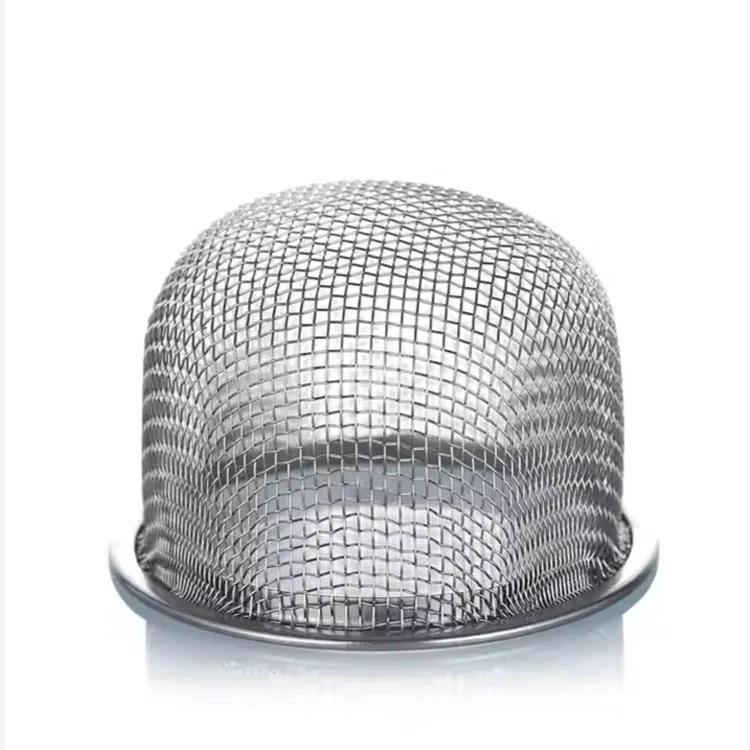

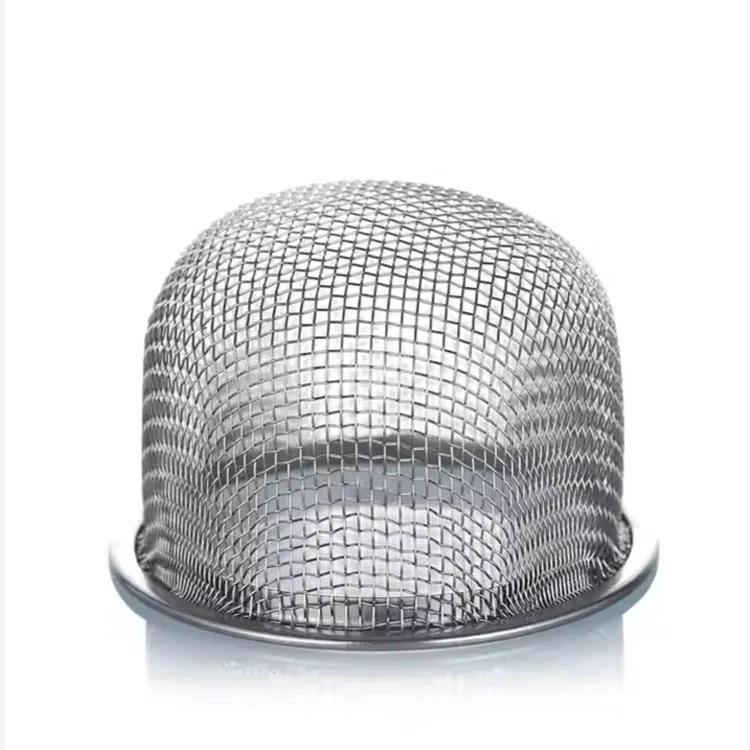

Key Product: Bowl Filter Screens – Technical Overview

Bowl Filter Screens are advanced filtration components crafted with precision, often utilizing stainless steel expanded sheet as the core filtering layer. They provide excellent strength, anti-clogging properties, and extended service life.

- Material Options: SS304, SS316L, Nickel alloys

- Typical Mesh Size: 10–500 mesh (customizable)

- Standard Diameter: 25mm–1200mm

- Filter Efficiency: Up to 99.97% (per ISO 16889)

- Operating Temperature: -200°C to +600°C

- Industry Certifications: ISO 9001, FDA, ANSI compliance

- Applications: Petrochemical refining, water & wastewater, metallurgy, food & beverage, pharmaceuticals

The layered construction allows for gradual filtration, minimizing pressure drops and frequent maintenance. Various frame weldings and screening configurations result in perfect customization for both high-flow and fine-filtration needs.

- Filtration efficiency: Improved by 23%

- Service intervals: Extended from 6 to 15 months

- Pump downtime: Reduced by 54%

- Return on investment: Within 10 months

Bowl Filter Screens vs. Traditional Filter Elements: Visual Analysis

Key Advantages of Stainless Steel Expanded Sheet in Filtration and Architecture

- Strength-to-Weight Ratio: The special expansion process preserves metal integrity, minimizing weight but maximizing load capability—critical for industrial and architectural needs.

- Anti-Clogging Design: Unique mesh geometry prevents particle accumulation, offering long-term stability for high-particulate flows.

- Superior Corrosion Resistance: Stainless alloys minimize maintenance and downtime in harsh environments (saline, acidic, alkali conditions).

- Sustainability: Nearly 100% material utilization reduces production waste, aligning with ISO 14001 guidelines.

- Design Versatility: Available in numerous mesh shapes and patterns for both strength-critical and decorative expanded metal mesh usages.

Certifications: QH Filter’s Bowl Filter Screens and stainless steel expanded sheet products are manufactured under strict ISO/ASTM standards (including ISO 9001:2015), with traceability and quality auditing in collaboration with clients from Siemens, BASF, Sinopec, and Veolia.

Vendor Comparison: Why Choose QH Bowl Filter Screens?

| Criteria | QH Filter | Generic Vendor |

|---|---|---|

| Material Purity | Proven 304/316L, Certificates provided | Mixed/incomplete batches |

| Welding & Assembly | Robotic precision, X-ray tested | Hand welded, inconsistent |

| Testing Standards | ISO 9001, ISO 16889, FDA, ANSI | Basic/absent checks |

| Customization | 10–500 mesh, 20+ shapes | Limited |

| After-sales/Support | 24 hrs response, full technical docs | Email only |

| Warranty | Up to 18 months | 6 months typical |

| Typical Delivery | 7–15 working days (ISO traceable) | 3–6 weeks |

QH Filter stands as an industry-certified provider, trusted by Fortune 500 and national infrastructure partners for their rapid supply, full specs transparency, and lifecycle service.

Customization Options & Engineering Support

- Mesh Configurations: Diamond, hexagonal, round hole, or bespoke geometries

- Frame/Welding Types: Rimmed, open, multi-layered, robot or manual welding as specified

- Size Range: Diameters from 25mm up to 1.2 meters

- Filter Grade: 10 to 500 mesh, layered counts up to 10 ply

- Logistics: Safe, export-grade packaging; specialty labels & barcoding

- Documentation: 3.1 mill certs, batch testing, MTRs provided

QH engineers are available for free consultation, CAD design, and on-site installation guidance for complex industrial retrofits.

Applications & Reference Projects

Petrochemical & Oil Refining

- Desalination pre-filtration

- Catalyst bed support

- Offshore platform screens

Water & Wastewater Treatment

- Pump intake straining

- RO pre-filter modules

- Biological reactor protection

Architecture & Decor

- Balustrades, pool cages

- Façade panels

(using decorative expanded metal mesh)

Client Testimonial (2023, Southeast Asian refinery): “QH’s stainless steel expanded sheet bowl filter screens have halved our filter replacement frequency, and our line pressure remains stable. The local technical support impressed us.”

FAQ: Stainless Steel Expanded Sheet & Bowl Filter Screens

- 1. What is a stainless steel expanded sheet?

- A stainless steel expanded sheet is a single solid sheet of stainless steel that has been simultaneously slit and stretched to form an array of diamond, hexagonal, or custom mesh openings, maintaining full material integrity without welding.

- 2. How does mesh size impact filtration?

- Smaller mesh sizes (higher mesh count) provide finer filtration, suitable for particulate sizes as small as 10 microns, while larger mesh enable higher flow rates in straining applications. Bowl Filter Screens can be tailored from 10 to 500 mesh as needed.

- 3. What materials are commonly used?

- SS304 and SS316L are most frequent for corrosion resilience; nickel alloys are available upon request for ultra-aggressive environments (e.g., high chlorides or acids).

- 4. What standards govern manufacturing?

- ISO 9001:2015 for quality management, ASTM F1267 (expanded metal), ISO 16889 (filter performance), and FDA requirements for food/pharma. Every QH bowl filter screen is traceable via batch and inspection ID.

- 5. What is the typical delivery cycle?

- Standard lead time for bowl filter screens is 7–15 business days depending on quantity, complexity, and finishing requirements, with expedited orders possible.

- 6. How is a bowl filter screen installed in a pipeline or housing?

- Each unit is supplied with fitment instructions; options include clamp, groove, or bolt mounting. For high-pressure or critical service, mounting may be robot-welded for zero leakage per EN 12266-1.

- 7. What warranties and after-sales support are provided?

- All QH bowl filter screens are warranted for up to 18 months, including installation and commissioning support, on-site troubleshooting, and supply of MRO spares (per service agreement).

Quality Assurance, Certifications & Service

- Full ISO 9001, FDA, ASTM, RoHS compliance, and third-party inspection (SGS/BV available on request)

- Lot-by-lot batch testing, including salt spray, pressure, and microstructure analysis

- Individual test certificates, 3.1 Material Traceability Reports (MTR) for every order

- Dedicated technical engineers available for post-sales troubleshooting

Warranty: 18-month warranty from delivery; replacements or technical service within 24 hours of notice for critical process lines.

Client Support: 24x7 response globally; on-site installation/inspection for major accounts.

Ordering, Shipping, & Guarantee

- MOQ: Flexible; single-piece trial orders available

- Lead Times: 7–15 working days; 3–5 days for urgent supply

- Packing: Wooden cases, vacuum-packing for export; waterproof/barcoded

- Delivery: Worldwide (Incoterms: FOB, CIF, DAP, EXW)

- Traceability: Full documentation packet with every shipment

For a quote or detailed datasheet, visit https://www.qhfilter.com/bowl-filter-screens.html

Further Reading & References

- ASTM International – Expanded Metal Standard: ASTM F1267

- Filtration+Separation Magazine: “Advanced Mesh Filtration Trends 2023” – Link