Photovoltaic Fence: Sustainable Security with Solar Power

The Evolving Landscape of Photovoltaic Fencing Solutions

In an era defined by increasing demands for sustainable infrastructure and robust security, the photovoltaic fence emerges as a groundbreaking innovation, seamlessly integrating perimeter security with renewable energy generation. This dual-purpose system transcends traditional fencing, offering a dynamic solution for industries seeking enhanced operational efficiency, reduced carbon footprints, and improved asset protection. The concept of a solar panel fence is rapidly gaining traction across various sectors, driven by global trends towards decarbonization, energy independence, and advanced security protocols. Market analysis indicates a significant compound annual growth rate (CAGR) in the integrated solar solutions market, reflecting a strong preference for multi-functional technologies. Early adoption cases highlight substantial reductions in grid electricity consumption, alongside fortified physical security. As industries grapple with fluctuating energy costs and escalating security threats, the strategic deployment of photovoltaic fence systems presents a compelling economic and environmental proposition. This innovative approach not only safeguards critical infrastructure but also contributes actively to a facility's energy requirements, embodying a forward-thinking investment in sustainable and secure operations.

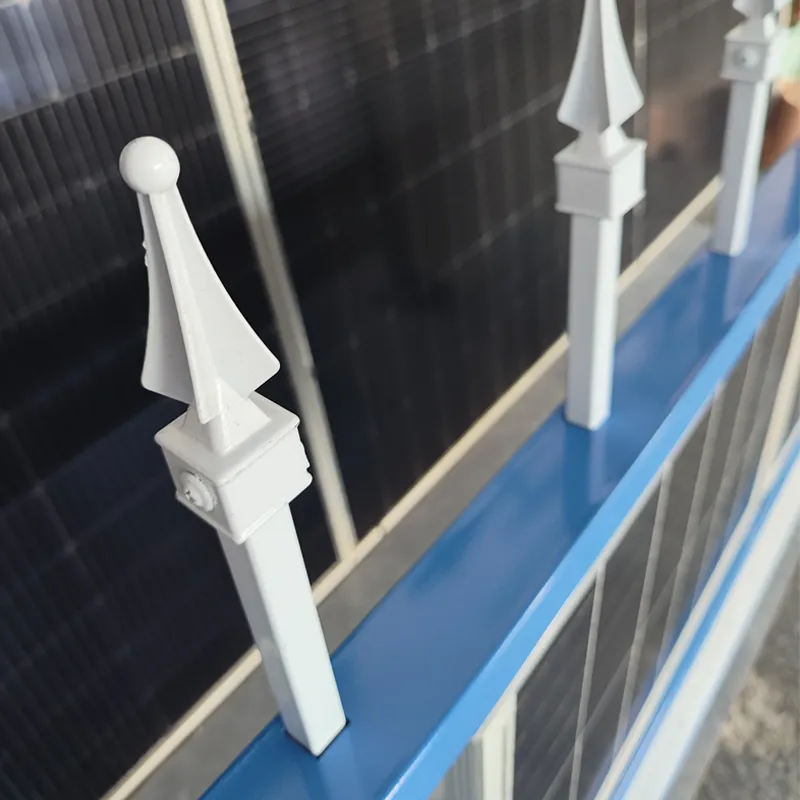

The increasing adoption of solar fencing solutions is a testament to their versatility and tangible benefits across diverse operational landscapes. From industrial complexes requiring robust perimeter control to remote sites in need of self-sufficient power, these fences offer a scalable and adaptive framework. Key industry trends indicate a shift from standalone security measures to integrated smart systems, where energy generation capability becomes a core component of the security infrastructure. This synergy not only optimizes space utilization but also provides critical power for surveillance equipment, lighting, and other ancillary systems without reliance on the main grid, thus enhancing resilience during outages. Furthermore, the aesthetic integration of solar panels within fence designs addresses concerns regarding visual impact, making them suitable for a broader range of applications including commercial properties and even residential developments seeking a blend of security and sustainability. The global push for Net-Zero emissions and stricter environmental regulations further accelerates the demand for such innovative green technologies, positioning the photovoltaic fence at the forefront of sustainable infrastructure development.

Technical Deep Dive: Materials, Manufacturing, and Quality Standards

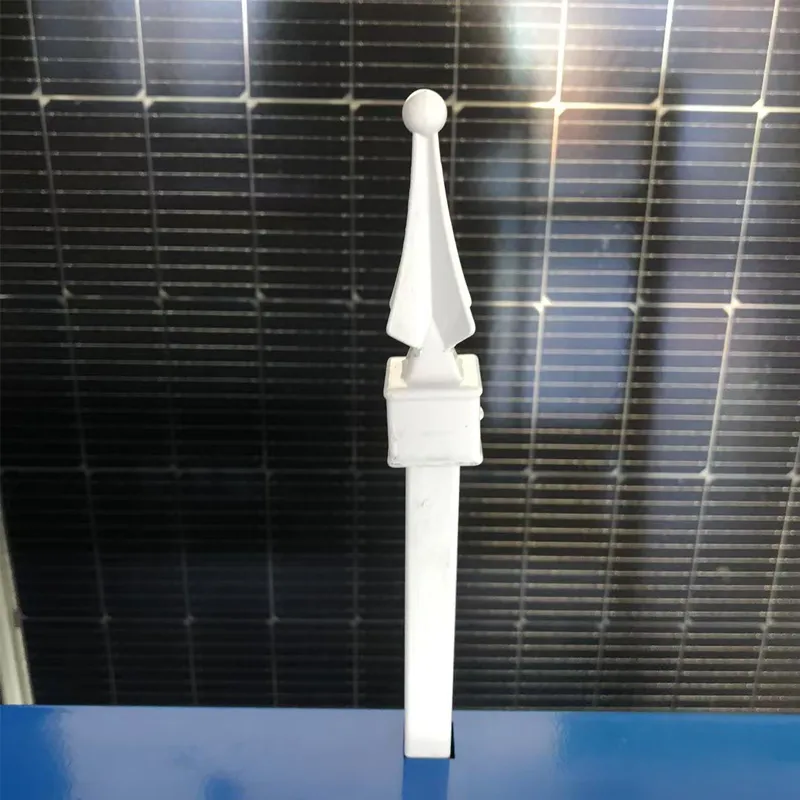

The structural integrity and long-term performance of a photovoltaic fence are fundamentally reliant on the meticulous selection of materials and advanced manufacturing processes. Typically, the fencing framework is constructed from high-strength galvanized steel or corrosion-resistant aluminum alloys, often subjected to hot-dip galvanizing and powder coating processes to ensure maximum durability and resistance to environmental degradation, including harsh weather and chemical exposure common in industrial settings. These materials are chosen for their excellent strength-to-weight ratio and ability to withstand significant wind and snow loads, typically designed to meet or exceed regional building codes and standards such as ASTM F2453 for perimeter security systems. The solar modules integrated into the fence are predominantly high-efficiency monocrystalline silicon panels, renowned for their superior performance in low-light conditions and higher power output per square meter. These panels undergo stringent manufacturing processes, including precision cell cutting, meticulous lamination, and framing, adhering to international standards like IEC 61215 for terrestrial photovoltaic modules and IEC 61730 for PV module safety qualification.

The manufacturing process for a photovoltaic fence involves a precise sequence of operations, beginning with the fabrication of structural components using advanced techniques such as CNC machining, automated welding, and precision stamping, ensuring uniform dimensions and ease of assembly. For specialized components requiring high strength and intricate shapes, techniques like precision casting or forging may be employed. Each batch of raw materials, from steel coils to silicon wafers, undergoes rigorous incoming quality inspection (IQC) to verify compliance with material specifications and purity levels. During assembly, critical joints and connections are engineered for optimal load bearing and long-term stability, often featuring proprietary interlocking designs that enhance structural rigidity while simplifying installation. Post-assembly, comprehensive quality control (QC) testing is paramount. This includes visual inspections for defects, mechanical load testing to simulate environmental stresses, electrical performance testing of PV modules (e.g., flash testing for IV curve measurement), and insulation resistance tests. Adherence to certifications like ISO 9001 for quality management systems and ISO 14001 for environmental management ensures that every component of the solar panel fence meets global benchmarks for reliability and sustainability. The expected service life for integrated PV modules often exceeds 25 years with less than 0.5% annual degradation, while the robust fence structure is designed for a lifespan of 30+ years, offering a durable and long-term investment.

Diverse Applications and Sector-Specific Advantages

The adaptability of the photovoltaic fence makes it an ideal solution for a multitude of industrial and commercial applications, each benefiting from its unique blend of security and energy generation. In the petrochemical industry, where robust perimeter security is critical due to hazardous materials and high-value assets, solar fencing provides a formidable physical barrier while simultaneously powering surveillance cameras, access control systems, and perimeter lighting, reducing reliance on the grid and enhancing resilience against power outages. For metallurgical plants, often located in remote areas with high energy consumption, a photovoltaic fence offers a sustainable power source for essential operations and security infrastructure, mitigating high electricity costs and contributing to corporate sustainability goals. In the water supply and drainage sector, these fences protect treatment plants, pumping stations, and reservoirs, providing autonomous power for monitoring equipment and ensuring continuous operation of vital systems even in isolated locations. The inherent anti-corrosion properties of the materials used in these fences are particularly beneficial in environments with high humidity or exposure to corrosive substances, ensuring long-term structural integrity and minimal maintenance.

Beyond traditional heavy industries, the photovoltaic fence demonstrates significant utility in safeguarding data centers, telecommunications infrastructure, and other critical facilities where uninterrupted power and advanced security are non-negotiable. These installations require constant surveillance and energy supply for their sensitive equipment, making the integrated power generation of a fence solar system exceptionally valuable. Similarly, in agricultural perimeters or large-scale farming operations, these fences can power remote irrigation systems, animal monitoring devices, and electric gates, significantly improving operational efficiency and reducing labor costs in sprawling landscapes. For military bases, airports, and other high-security zones, the dual functionality offers an unparalleled advantage, combining physical deterrence with continuous power for advanced detection and response systems. The ability to generate clean energy on-site also provides a tangible benefit in terms of energy independence and reduced operational expenditures, often leading to a compelling return on investment through lower utility bills and potential feed-in tariffs. The versatility and robustness of this technology underscore its growing importance in modern infrastructure development across global sectors.

Key Technical Parameters and Performance Metrics

Understanding the critical technical parameters of a photovoltaic fence is essential for optimizing its performance and ensuring it meets specific project requirements. These parameters dictate the system's efficiency, durability, and suitability for various environmental conditions. For the integrated solar modules, key metrics include nominal power output (e.g., 100W to 400W per panel segment), module efficiency (typically 18% to 22% for monocrystalline), open-circuit voltage (Voc), short-circuit current (Isc), and temperature coefficients which describe how performance changes with temperature fluctuations (e.g., -0.3% to -0.4% per °C for power). The fence structure itself is evaluated based on its wind load resistance (e.g., up to 2400 Pa for wind, 5400 Pa for snow), material tensile strength, and corrosion resistance ratings (e.g., salt spray test compliance for C5 environments). These specifications are crucial for ensuring the system's resilience against extreme weather events and its long-term integrity in harsh industrial settings. Detailed understanding of these metrics allows for precise system sizing and configuration, maximizing energy harvest and security efficacy.

Typical Photovoltaic Fence Technical Specifications

| Parameter | Typical Value Range | Unit |

|---|---|---|

| Solar Module Type | Monocrystalline PERC | N/A |

| Module Power Output (per meter) | 50 - 150 | Wp/meter |

| Module Efficiency | 18 - 22 | % |

| System Voltage | 12 / 24 / 48 (DC), 230 / 400 (AC) | V |

| Wind Load Resistance | Up to 2400 | Pa |

| Snow Load Resistance | Up to 5400 | Pa |

| Operating Temperature Range | -40 to +85 | °C |

| Fence Material | Hot-dip Galvanized Steel / Aluminum Alloy | N/A |

| Ingress Protection (IP) Rating | IP67 (PV modules), IP65 (Junction Box) | N/A |

Performance metrics extend beyond static specifications to include real-world energy yield predictions, which factor in local solar irradiance data, shading analysis, and system losses from temperature, wiring, and inverter efficiency. For instance, a well-designed solar panel fence in a high-irradiance region could generate significantly more power than one in a lower irradiance zone, influencing its economic viability. Factors such as azimuth and tilt angle, though less flexible in a fence structure than rooftop installations, are optimized during design to maximize sunlight exposure. Monitoring systems are often integrated to track real-time power generation, identify faults, and ensure optimal performance, providing valuable data for maintenance scheduling and energy management. The balance between maximum power point tracking (MPPT) efficiency of the inverter and the battery storage capacity determines the system's ability to provide continuous power, especially during periods of low sunlight or peak demand, solidifying the role of the photovoltaic fence as a resilient and reliable energy source.

Strategic Advantages and Return on Investment (ROI)

Investing in a photovoltaic fence offers a multifaceted strategic advantage that extends far beyond conventional security solutions. Foremost is the dual-purpose functionality, combining robust physical perimeter protection with on-site renewable energy generation. This significantly reduces reliance on grid electricity, leading to substantial long-term savings on utility bills, which can be particularly impactful for large industrial facilities with extensive perimeters. Furthermore, the ability to generate clean energy contributes directly to a company's sustainability objectives, enhancing its corporate social responsibility (CSR) profile and potentially qualifying for various government incentives, tax credits, or carbon credits, thus improving the overall economic attractiveness. The modular design of solar fencing allows for rapid deployment and scalability, adapting to varying site requirements and future expansion needs with minimal disruption. The integrated nature of the system also reduces the land footprint compared to separate solar farms and traditional fencing, optimizing valuable real estate.

From an economic perspective, the Return on Investment (ROI) for a photovoltaic fence is compelling, typically manifesting within 5-8 years depending on energy prices, system size, and local solar irradiance. This calculation considers initial capital expenditure, operational savings from reduced electricity consumption, potential revenue from excess energy sold back to the grid (feed-in tariffs), and maintenance costs. Beyond the direct financial benefits, the enhanced security features provide an invaluable return by deterring intrusions, protecting high-value assets, and potentially reducing insurance premiums related to theft or vandalism. Many systems can be integrated with advanced security technologies such as intelligent surveillance cameras, motion sensors, and alarm systems, all powered by the fence itself, creating a self-sufficient and highly effective security barrier. This self-reliance also mitigates risks associated with grid power outages, ensuring continuous operation of critical security systems. The long lifespan of components (25+ years for PV modules, 30+ years for structure) ensures sustained benefits over decades, positioning the solar panel fence as a robust and future-proof investment for any B2B entity prioritizing security, sustainability, and operational autonomy.

Manufacturer Comparison and Customization Options

Selecting the right manufacturer for a photovoltaic fence is a critical decision that influences system performance, longevity, and overall project success. Key factors to consider include the manufacturer's experience in both solar and security solutions, their track record of successful installations, adherence to international quality standards (e.g., ISO, CE, UL), and their commitment to research and development. Reputable manufacturers often distinguish themselves by offering advanced module technologies, superior structural engineering, and comprehensive warranty programs. While some manufacturers may focus on cost-effectiveness, others prioritize maximum efficiency or specialized applications, such as extreme weather resilience or integration with advanced smart grid technologies. A thorough due diligence process should involve reviewing case studies, client testimonials, and third-party certifications. The market offers a range of solar fencing providers, varying in their specialization from high-performance systems for critical infrastructure to more generalized solutions for commercial perimeters, necessitating a tailored approach to selection based on specific operational needs and budget constraints.

Customization is a significant advantage offered by leading photovoltaic fence manufacturers, ensuring the system precisely fits the unique requirements of each project. This can involve tailoring fence height and length to specific perimeter dimensions, optimizing panel power output and energy storage capacity based on the site's energy demands and solar irradiance, and selecting specialized coatings for extreme environmental conditions like high salinity or industrial pollutants. Furthermore, advanced integration with existing or new security systems, such as CCTV cameras, motion detectors, thermal imaging, and access control, is crucial. Manufacturers can provide tailored mounting solutions to accommodate various terrains, from flat ground to uneven slopes, and offer different aesthetic finishes to blend with the surrounding environment. The project delivery cycle typically encompasses initial consultation, site assessment, detailed engineering design, material procurement, manufacturing, logistics, installation, and commissioning. A professional manufacturer will offer transparent communication throughout this process, provide clear timelines (e.g., 8-12 weeks for design to delivery, depending on complexity), and ensure that all components are delivered ready for seamless assembly, guaranteeing a smooth transition from concept to fully operational fence solar system.

Comprehensive Customer Support and Assurance

Reliable customer support and robust assurance policies are paramount when investing in advanced infrastructure like a photovoltaic fence. Leading manufacturers typically offer multi-tiered warranty programs that cover both the product and its performance. For the PV modules, a standard product warranty of 10-12 years against defects in materials and workmanship is common, complemented by a linear performance warranty guaranteeing 90% of rated power output for the first 10 years and 80% for 25 years. The structural components of the solar panel fence often come with a separate warranty, typically 20-30 years, reflecting their designed longevity and durability. After-sales service is equally crucial, encompassing technical support for troubleshooting, routine maintenance schedules, and timely availability of spare parts. Many providers offer service level agreements (SLAs) to ensure rapid response times for any operational issues. Client feedback consistently highlights the importance of responsive and knowledgeable support teams for maintaining system uptime and maximizing energy generation over the system's lifespan.

Frequently Asked Questions (FAQ)

Q: How does a photovoltaic fence perform in extreme weather conditions?

A: Photovoltaic fences are designed to withstand harsh environmental conditions. The solar modules are certified for high wind (up to 2400 Pa) and snow loads (up to 5400 Pa), and operate efficiently in temperatures ranging from -40°C to +85°C. The fence structure materials are selected for their corrosion resistance and durability, ensuring long-term integrity even in challenging climates. Regular maintenance, though minimal, ensures optimal performance across varying weather patterns.

Q: What is the typical maintenance requirement for a solar fencing system?

A: Maintenance for a photovoltaic fence is generally low. It primarily involves periodic cleaning of solar panels to ensure maximum light absorption and visual inspection of the fence structure for any physical damage. Advanced systems include remote monitoring capabilities, which alert operators to any performance anomalies, allowing for predictive maintenance. This minimal upkeep contributes to the system's cost-effectiveness over its long operational lifespan.

Q: Can a photovoltaic fence be integrated with existing security systems?

A: Absolutely. A key advantage of modern photovoltaic fence solutions is their modularity and compatibility with a wide range of existing security infrastructure. This includes seamless integration with CCTV camera systems, motion sensors, access control systems, and perimeter intrusion detection systems (PIDS). The fence can provide autonomous power to these components, enhancing their resilience and reducing the need for extensive trenching and electrical wiring, making it an ideal upgrade for enhancing overall site security without complex overhauls.

Future Outlook and Sustainability Impact

The future of photovoltaic fence technology is poised for continuous innovation, driven by advancements in solar cell efficiency, energy storage, and smart grid integration. Emerging trends include the development of bifacial solar modules that can capture sunlight from both sides, potentially increasing energy yield by up to 25% for vertical installations like fences. Furthermore, the integration of advanced battery energy storage systems (BESS) will enhance energy independence, allowing facilities to store excess solar power for use during peak demand hours or at night, thereby maximizing self-consumption and reducing reliance on grid power. The concept of a solar panel fence is also evolving towards 'smart fence' capabilities, incorporating IoT sensors for enhanced real-time monitoring of both energy production and security breaches, enabling predictive maintenance and more sophisticated threat detection. This convergence of renewable energy generation, advanced security, and smart technology positions the photovoltaic fence as a cornerstone of sustainable and resilient infrastructure development globally.

The profound sustainability impact of adopting photovoltaic fence systems aligns perfectly with global environmental mandates and corporate sustainability goals. By transforming idle perimeter space into active energy generators, these fences significantly reduce carbon emissions associated with conventional electricity sources, contributing directly to a facility's decarbonization efforts. This not only improves air quality but also reduces the overall environmental footprint of industrial and commercial operations. The long operational lifespan and minimal maintenance requirements further enhance their sustainability profile, reducing waste and resource consumption over time. As industries increasingly commit to Net-Zero targets and embrace circular economy principles, the demand for integrated, multi-functional green technologies like solar fencing is expected to accelerate. This technology exemplifies a forward-thinking approach to infrastructure that meets both security imperatives and environmental responsibilities, paving the way for a more sustainable and energy-independent future for critical assets and operations worldwide. The commitment to continuous innovation in materials and system integration will only solidify its role as a leading solution in the transition to renewable energy.

References

- International Electrotechnical Commission (IEC) Standards for Photovoltaic Devices.

- American Society for Testing and Materials (ASTM) Standards for Fencing and Security Systems.

- ISO 9001 and ISO 14001 Quality and Environmental Management System Standards.

- National Renewable Energy Laboratory (NREL) publications on PV system performance and reliability.

- World Energy Council (WEC) reports on global energy trends and sustainable infrastructure.