Durable Mild Steel Expanded Sheet High-Strength Expanded Metal Mesh Solutions

- Introduction to Mild Steel Expanded Sheet

- Technical Advantages & Material Specifications

- Performance Comparison: Leading Manufacturers

- Customization Options for Industrial Needs

- Real-World Applications Across Industries

- Cost Efficiency & Long-Term Durability

- Why Choose Mild Steel Expanded Metal Solutions

(mild steel expanded sheet)

Understanding Mild Steel Expanded Sheet

Mild steel expanded sheet, a versatile perforated material, combines structural integrity with functional design. With a carbon content below 0.25%, this metal mesh offers superior weldability and formability compared to high-carbon alternatives. Typical applications range from architectural cladding to heavy-duty industrial filters, leveraging its 30-50% open area ratio for optimal airflow and weight reduction.

Technical Advantages & Material Specifications

Manufactured through simultaneous slitting and stretching, mild steel expanded sheet

s achieve tensile strengths up to 500 MPa. Key metrics include:

- Thickness range: 0.5mm to 6mm

- Standard sheet sizes: 1,200mm x 2,400mm or custom dimensions

- Temperature resistance: -50°C to 400°C

Galvanized variants demonstrate 75% higher corrosion resistance in ASTM B117 salt spray tests compared to untreated sheets.

Performance Comparison: Leading Manufacturers

| Manufacturer | Price/sq.m ($) | Thickness Tolerance | Lead Time |

|---|---|---|---|

| SteelMesh Pro | 18.50 | ±0.1mm | 5 days |

| Metex Industrial | 22.75 | ±0.05mm | 7 days |

| AlloyWorks | 16.90 | ±0.2mm | 10 days |

Customization Options for Industrial Needs

Advanced fabrication techniques enable:

- Precision laser cutting for ±0.3mm dimensional accuracy

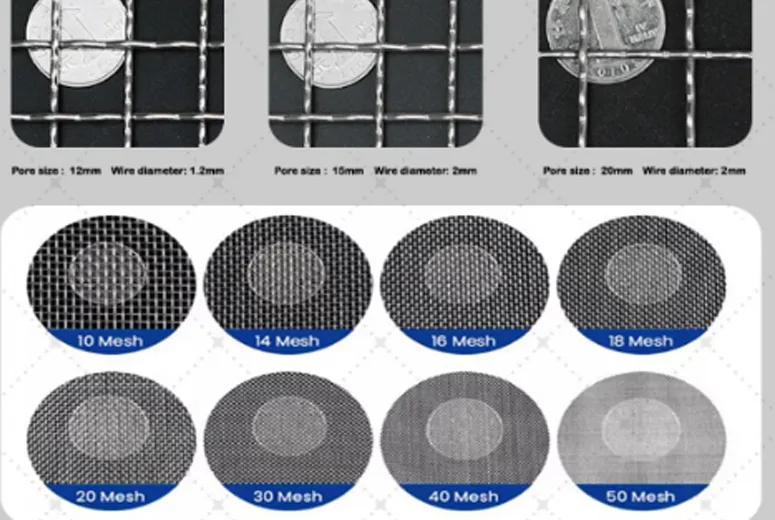

- Custom hole patterns (diamond, round, square) with 2mm-50mm openings

- Surface treatments: powder coating, hot-dip galvanizing, or PVC laminates

Recent projects have achieved 15% material savings through optimized sheet nesting algorithms.

Real-World Applications Across Industries

In automotive manufacturing, expanded mild steel reduces vehicle weight by 8-12% when used in interior panels. Construction projects report 20% faster installation times compared to solid steel sheets for walkway surfaces. The food processing industry utilizes fine-mesh variants (0.8mm strand width) for high-flow filtration systems.

Cost Efficiency & Long-Term Durability

Lifecycle analysis shows:

- 30% lower maintenance costs over 10 years vs. aluminum alternatives

- 95% recyclability rate with ISO 14001-compliant production

- 15-year structural warranty on galvanized products

Optimizing Projects with Mild Steel Expanded Metal

For engineers specifying expanded mild steel components, consider load-bearing requirements early in design phases. Recent case studies demonstrate 18% cost reductions when integrating expansion ratios during CAD modeling. Partnering with certified suppliers ensures compliance with ASTM A1011 standards while maintaining competitive pricing structures.

(mild steel expanded sheet)

FAQS on mild steel expanded sheet

Q: What is a mild steel expanded sheet?

A: A mild steel expanded sheet is a metal mesh created by cutting and stretching mild steel sheets, forming diamond-shaped patterns. It is lightweight, durable, and ideal for applications requiring ventilation or safety. Its affordability makes it popular in construction and industrial settings.

Q: How is expanded mild steel manufactured?

A: Expanded mild steel is produced by slitting and stretching mild steel coils under high tension, creating uniform openings. This cold-working process retains the material’s strength while reducing weight. The result is a versatile mesh used for fencing, grating, and filters.

Q: What are common uses for mild steel expanded metal mesh?

A: Mild steel expanded metal mesh is widely used for walkways, machine guards, and partitions due to its sturdiness. It also serves as reinforcement in concrete structures and as protective screens. Its open design allows airflow and light penetration.

Q: What advantages does mild steel expanded sheet offer over solid sheets?

A: Mild steel expanded sheets provide better strength-to-weight ratio and cost-efficiency compared to solid sheets. Their perforated design reduces material usage while maintaining structural integrity. They also offer slip resistance and improved airflow in applications.

Q: Can mild steel expanded sheet be used outdoors?

A: Yes, but mild steel expanded sheet requires protective coatings like galvanization or paint to prevent rust. Regular maintenance ensures longevity in outdoor environments. It’s commonly used for fences, facades, and sunshades with proper treatment.