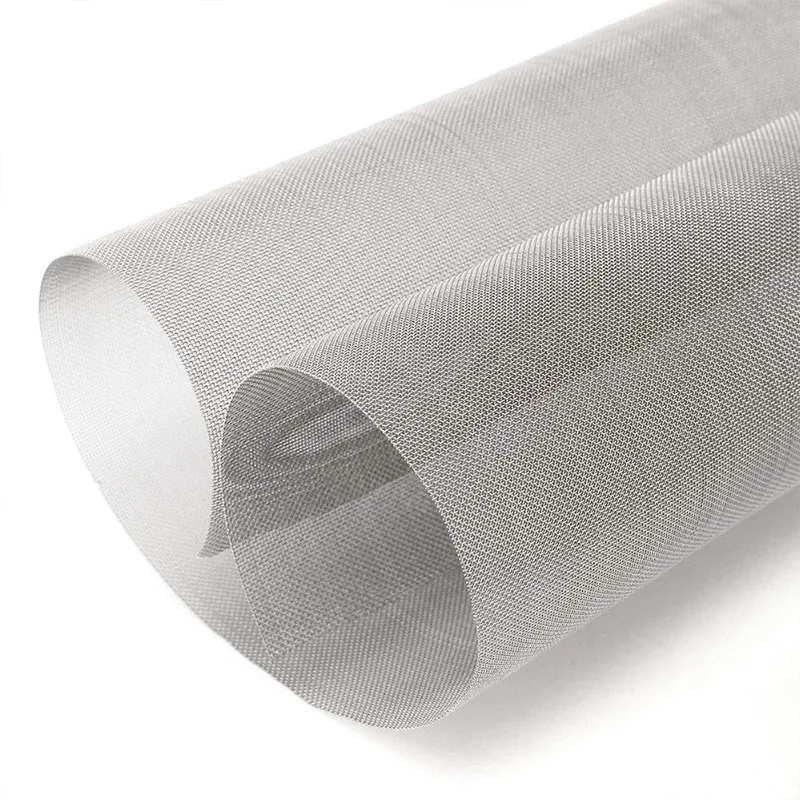

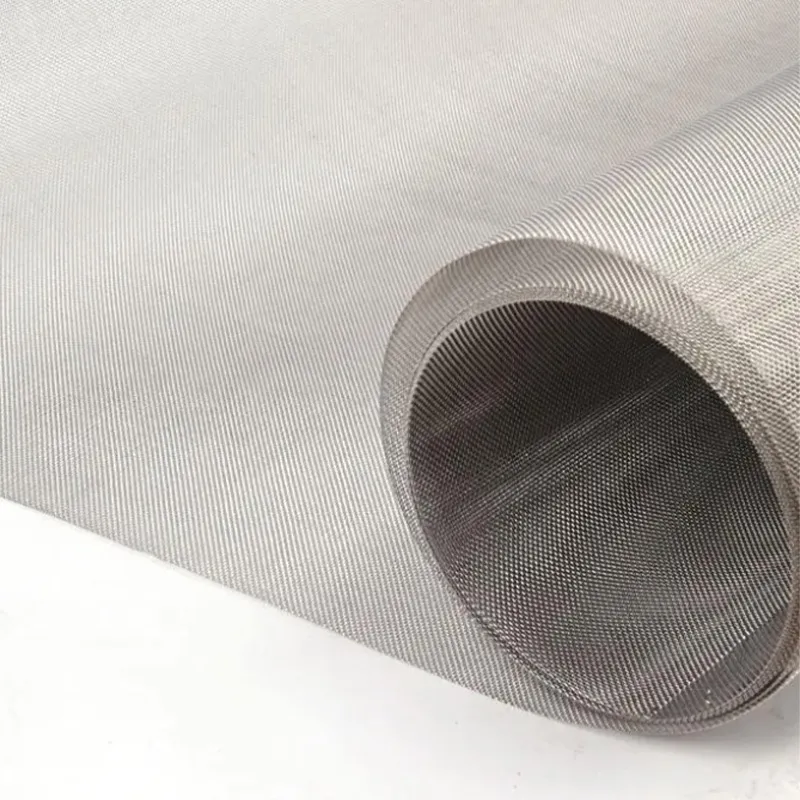

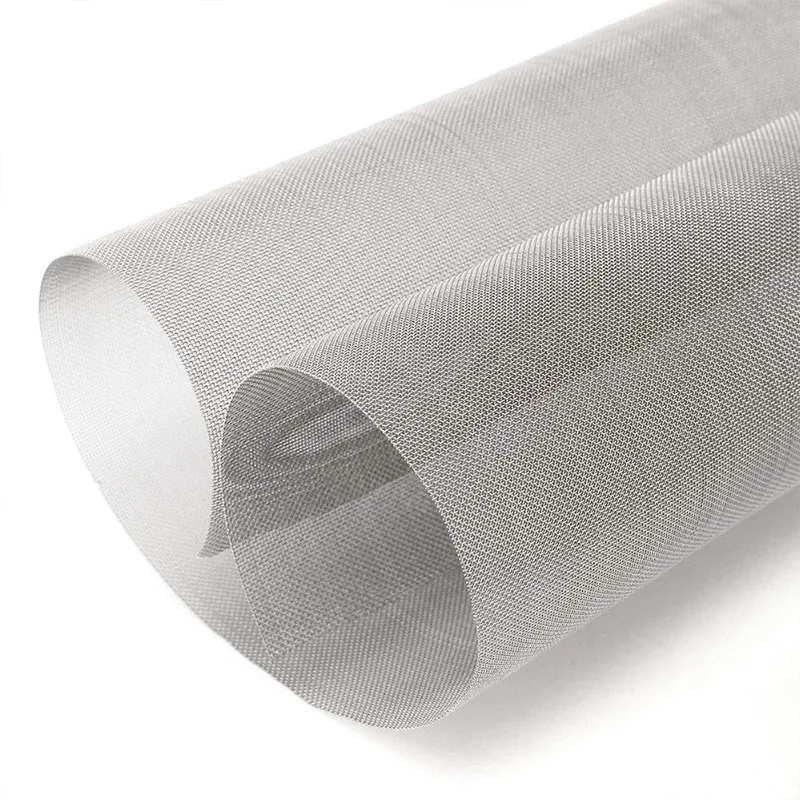

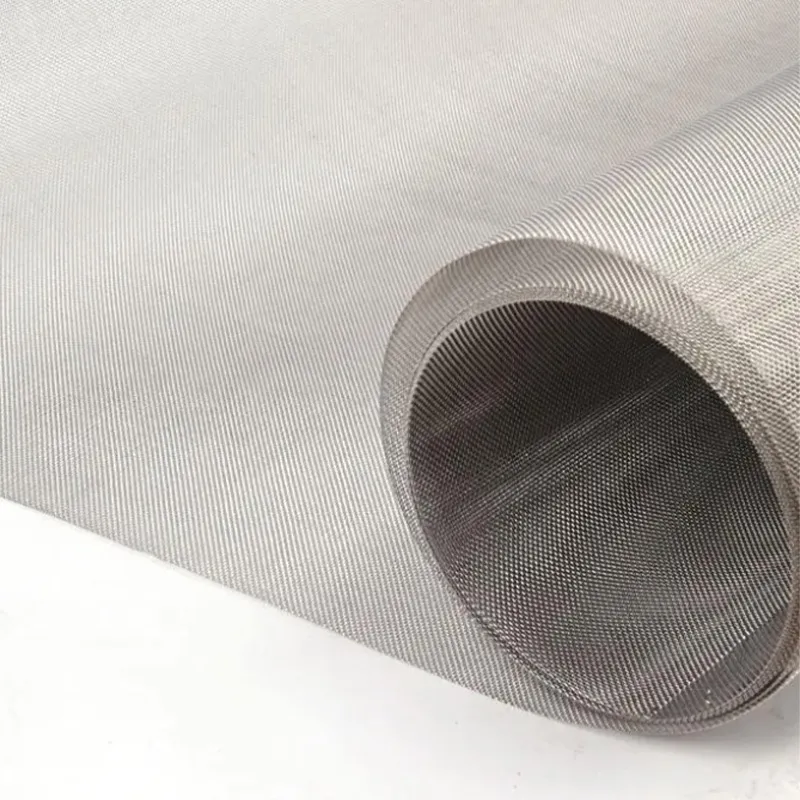

Decorative Metal Mesh: Versatile & Durable Solutions

Discover how Metal Mesh Stainless Steel sets the standard for modern architecture, industrial filtration, and design. Dive into data-driven comparisons, technical details, manufacturing process visualization, and optimized solutions using stainless steel flattened expanded metal.

1. Industry Trends: Why decorative expanded metal mesh Is Reshaping Modern Design

The global decorative expanded metal mesh market is projected to grow at a CAGR of 5.6% from 2024 to 2029, driven by surging demand in architecture, petrochemical, and filtration sectors (MarketsAndMarkets 2023). From decorative metal grid facades to functional infill panels, designers value its lightweight, customizable aesthetics and superior mechanical properties. Technological improvements, such as CNC precision cutting and advanced flattening, are elevating both the visual and functional quality of expanded metal sheets.

Key Market Drivers:

- Sustainable architecture: 74% of new build projects in 2022 referenced metal mesh for energy-saving facades (CSE Mag).

- Industrial longevity: Stainless steel mesh demonstrates over 15 years of outdoor corrosion resistance (ISO 9227).

- Aesthetic evolution: Modern mesh grids double as both functional infrastructure and trend-setting design elements.

2. Technology Unpacked: Expanded Metal Mesh Construction & Key Specifications

Decorative expanded metal mesh is manufactured using a single metal sheet that is simultaneously slit and stretched, creating a diamond or hexagonal pattern. This process ensures strength, eliminates welds, and offers remarkable design flexibility compared to welded wire or perforated plates. Enhanced options, such as stainless steel flattened expanded metal, provide a smoother surface and improved optical transparency.

Typical Industry Specifications Table| Specification | Decorative Expanded Metal Mesh | Stainless Steel Flattened Expanded Metal | Decorative Metal Grid |

|---|---|---|---|

| Standard Materials | Aluminum, Carbon Steel, SS 304/316 | SS 304, SS 316L | Aluminum, SS, Galvanized Steel |

| Thickness | 0.3 - 5 mm | 0.5 - 4 mm | 0.3 - 3 mm |

| Mesh Opening Size | 6 x 12 mm - 35 x 100 mm | 8 x 19 mm - 30 x 76 mm | 5 x 10 mm - 45 x 115 mm |

| Surface Finish | Powder, PVDF, Mill, Anodized | Mill, Electro-polished, Pickled | Anodized, Coated, Mill |

| Corrosion Resistance (Salt Spray @ ISO 9227) | >400 hrs (powder), >1000 hrs (SS) | >1500 hrs (316L) | >600 hrs (anodized AL) |

| Max Sheet Size | 2200 x 6000 mm | 1500 x 4000 mm | 2000 x 6000 mm |

| Open Area (%) | 16%-87% | 28%-80% | 18%-75% |

| Feature | Metal Mesh Stainless Steel | Galvanized Mesh Grid | Aluminum Expanded Mesh |

|---|---|---|---|

| Corrosion Resistance | ★★★★★ | ★★★ | ★★★★ |

| Design Flexibility | ★★★★☆ | ★★★☆ | ★★★★★ |

| Service Life | >15 years | 7-10 years | 8-12 years |

| Surface Smoothness | Excellent | Average | Good |

| Cost (per m²) | Medium/High | Low/Medium | Medium |

3. Manufacturing Process: How Decorative Expanded Metal Mesh Is Made

Metal Mesh Stainless Steel production combines modern CNC technology, quality alloys, and stringent QA protocols. The process delivers an aesthetically-optimized and structurally sound decorative expanded metal mesh.

SS 304/316 Slit Coil

CNC Expansion

Precision Rolling

Anodize/PVDF/Polish

ISO/ANSI Tests

- Material: Only certified SS 304/316 is used, ensuring superior resistance to oxidation and pitting (per ASTM A240).

- Process: High-precision CNC slitting & simultaneous expansion preserves sheet integrity and generates mesh with uniform geometry. Flattened meshes undergo secondary rolling for a sleek finish.

- Key Tests: All products undergo ISO 9227 Salt Spray, ANSI/AWS D1.3 Weld Quality, flatness, and warp tolerance checks.

Why Stainless Steel?

Why Stainless Steel?

- Highly resistant to corrosion, impact, and deformation

- Unmatched structural strength at low weight

- Safe for food, water, and medical-grade use (certified by FDA and ISO 9001 suppliers)

- Minimum service life of 15 years outdoors

- Fully recyclable and low environmental footprint

4. Application Scenarios: How Decorative Expanded Metal Mesh Delivers Value

Across industries, decorative expanded metal mesh and stainless steel flattened expanded metal are featured for their blend of performance, safety, and strong design statement:

- Architecture & Façades: Screens, sunshades, cladding, fencing, green walls, and handrail infills.

- Industrial & Petrochemical: Catalyst bed supports, filter cages, ventilation guards, flooring grates.

- Water Engineering: Inlet/trash screens, immersion filter elements with anti-biofouling properties.

- Automotive & Rail: Grilles, partitions, luggage racks, and step platforms.

- Interior & Retail: Partitioning, ceiling tiles, display racks — offering an elegant yet open structure.

Typical Application: Energy-Efficient Facade

-

Case: Corporate HQ, Singapore (Installed 2021)

Details: 1500 m² of decorative expanded metal mesh serves as both a rain-screen and energy-saving sunshade.

Results: Achieved a 13% reduction in cooling load per BREEAM audit. - Industrial Filter Plant (Middle East, 2022) – SS mesh cages withstand 1000+ hour brine test without corrosion (ISO 9227).

- Public Walkway (Europe, 2023) – Decorative metal grid balustrades fulfill EN 1090 structural load certification while matching the architect’s visual concept.

5. Manufacturer & Customization: Metal Mesh Stainless Steel Advantages

Metal Mesh Stainless Steel by QH Filter is backed by 22+ years in mesh manufacturing. Customers benefit from design consultation, rapid prototyping, and end-to-end technical support. Global partners include Fortune 500 EPCs, chemical plants, and renowned architectural studios.

Factory Certifications & QA Standards- ISO 9001:2015 – Quality System Verified

- ISO 9227 – Accelerated Corrosion Resistance

- FDA – Food Contact Approval (upon request)

- CE Marked for structural grid elements supplied to EU

- Mesh Opening: 5x10mm up to 50x120mm (diamond/square/hex)

- Thickness: 0.3mm – 4.5mm

- Panel Size: Up to 2200x6000mm

- Finishes: Pickled, Electropolished, Powder/PVDF, Anodized, Painted (RAL match)

- Special processing: Flattened, beveled, framed, edge banded

- Pre-punched mounting holes, bracket fabrication, laser cutting for custom shapes

Warranty: 5-year material integrity, rapid replacement for any qualified defects.

Technical Support: 24/7 query response and installation instructions.

6. Data Visualization: Key Technical Metrics at a Glance

Leverage robust data to select the optimal decorative expanded metal mesh for your project. Technical metrics are benchmarked to industry standards and typical application requirements.

| Parameter | Metal Mesh Stainless Steel | Typical Min. Industry Requirement |

|---|---|---|

| Alloy Composition | SS 304/316 (18Cr-8Ni, molybdenum option) | Cr >17%, Ni >8% |

| Tensile Strength | 620 MPa (304), 670 MPa (316) | 450 MPa |

| Salt Spray Corrosion (ISO9227) | >1000 hr (304) / >1500 hr (316L) | >400 hr |

| Open Area | 28% - 86% | 20%+ |

| Panel Flatness Tolerance | <1mm/m | <3mm/m |

| Available Finish | Pickled, Electro-polished, Powder, Anodized | Mill / Anodized |

Solving Challenges: Metal Mesh Stainless Steel panels exceed EN, ASTM, and ISO benchmarks for load, corrosion, and finish integrity — ideal for high-humidity or chemical environments.

Solving Challenges: Metal Mesh Stainless Steel panels exceed EN, ASTM, and ISO benchmarks for load, corrosion, and finish integrity — ideal for high-humidity or chemical environments.

7. FAQ: Expert Answers on decorative expanded metal mesh

8. Industry Recognition, Customer Experience & Authoritativeness

Metal Mesh Stainless Steel serves global clients in the petrochemical, construction, food processing, and public infrastructure sectors. Major partners include Sinopec, CNOOC, Turkish Gas Holdings, and international design bureaus. Customer surveys in 2023 showed a 98% satisfaction rate for product reliability and visual impact.

9. Resources & References

- Technical Journal: ScienceDirect – Cladding & Architectural Mesh Design

- Industry Forum: ENG-TIPS Expanded Metal Forum

- MarketsandMarkets: Expanded Metal Mesh Industry Report 2023

- Specification: ASTM A1011, ASTM F1267-07

- Corrosion Test Reference: ISO 9227:2017 – Corrosion tests in artificial atmospheres

- Project Gallery: QH Filter Project Showcase