Decorative Expanded Metal Mesh: Stainless Steel & Flattened Designs

In the dynamic landscape of modern architecture, industrial design, and creative arts, materials that combine aesthetic appeal with unparalleled functionality are highly prized. Among these, decorative expanded metal mesh stands out as a true game-changer. This innovative product, often crafted from robust materials like stainless steel flattened expanded metal, offers an exceptional blend of strength, lightweight design, open area, and striking visual depth. From sophisticated building facades to secure and elegant railings, its applications are as diverse as the creative minds that employ it. This comprehensive guide delves into the intricate world of expanded metal mesh, exploring its technical prowess, diverse applications, manufacturing excellence, and why it represents a superior choice for a multitude of projects.

Industry Trends and Market Insights for Advanced Metal Mesh Solutions

The global market for expanded metal mesh is experiencing significant growth, driven by increasing demands in construction, automotive, filtration, and architectural sectors. Projections indicate a compound annual growth rate (CAGR) of over 5% for the next five years, with an estimated market value exceeding USD 15 billion by 2027. This growth is largely fueled by urbanization, infrastructure development, and a rising preference for sustainable, durable, and aesthetically pleasing materials. Specifically, decorative expanded metal mesh is seeing a surge in popularity in high-end architectural projects due to its ability to offer both privacy and visual transparency, while contributing to energy efficiency through effective sun shading. The trend towards sustainable building materials, coupled with the long life cycle and recyclability of stainless steel products like our Metal Mesh Stainless Steel, further positions expanded metal mesh at the forefront of modern material science.

Furthermore, the demand for custom solutions is escalating. Architects and designers are seeking unique patterns, finishes, and dimensions that standard meshes cannot provide. This pushes manufacturers to invest in advanced fabrication technologies and provide comprehensive design support, transforming suppliers into strategic partners in project realization. The market is also seeing an increased adoption of digital design tools, allowing for more precise specification and visualization of complex mesh patterns, leading to greater innovation in applications like decorative metal grid for artistic installations and building envelopes.

Understanding Decorative Expanded Metal Mesh: Technical Parameters & Features

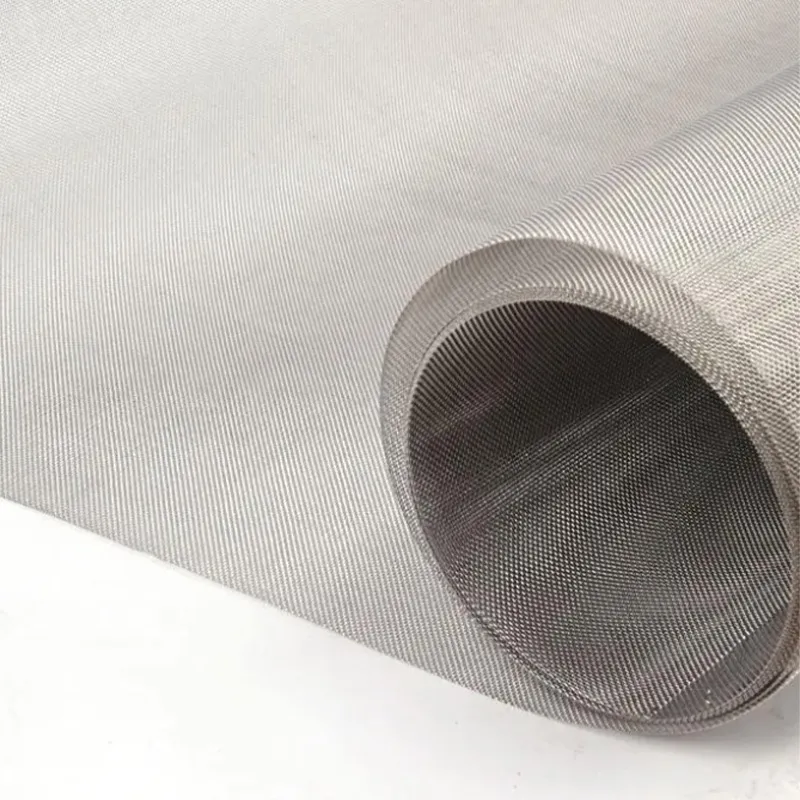

At its core, expanded metal mesh is a single, integral piece of metal that has been simultaneously slit and stretched, forming a diamond-shaped pattern of openings. Unlike woven mesh, this process creates no welds or interlocks, ensuring superior strength-to-weight ratio and eliminating potential failure points. When we speak of decorative expanded metal mesh, we are often referring to products with specific patterns, strand configurations, and finishes designed for aesthetic appeal.

Key Technical Terminology:

- LWD (Long Way of Design): The length of the diamond opening measured from bond to bond across the long dimension.

- SWD (Short Way of Design): The length of the diamond opening measured from bond to bond across the short dimension.

- Strand: The individual strips of metal forming the sides of the diamond pattern.

- Bond: The solid juncture where strands intersect, forming the unexpanded portion of the sheet.

- Strand Thickness: The thickness of the original sheet metal from which the mesh is expanded.

- Strand Width: The amount of metal fed through the expanding machine, determining the width of the individual strands.

- Open Area (%): The percentage of open space within the mesh, crucial for light transmission, airflow, and visual transparency. This is a critical parameter for decorative expanded metal mesh as it directly impacts its aesthetic and functional properties like sun shading or privacy.

The material choice significantly impacts the mesh's performance. Our Metal Mesh Stainless Steel is predominantly made from high-grade stainless steel (e.g., 304, 316), renowned for its exceptional corrosion resistance, strength, and longevity. This makes it ideal for both interior and exterior applications, even in harsh environments like coastal areas or industrial zones where chemical exposure is a concern.

Surface Finishes: Enhancing Aesthetic and Durability

Beyond the inherent beauty of stainless steel, decorative expanded metal mesh can undergo various finishing processes to enhance its appearance and functional properties:

- Mill Finish: The natural finish of the expanded metal, showcasing its raw, industrial beauty.

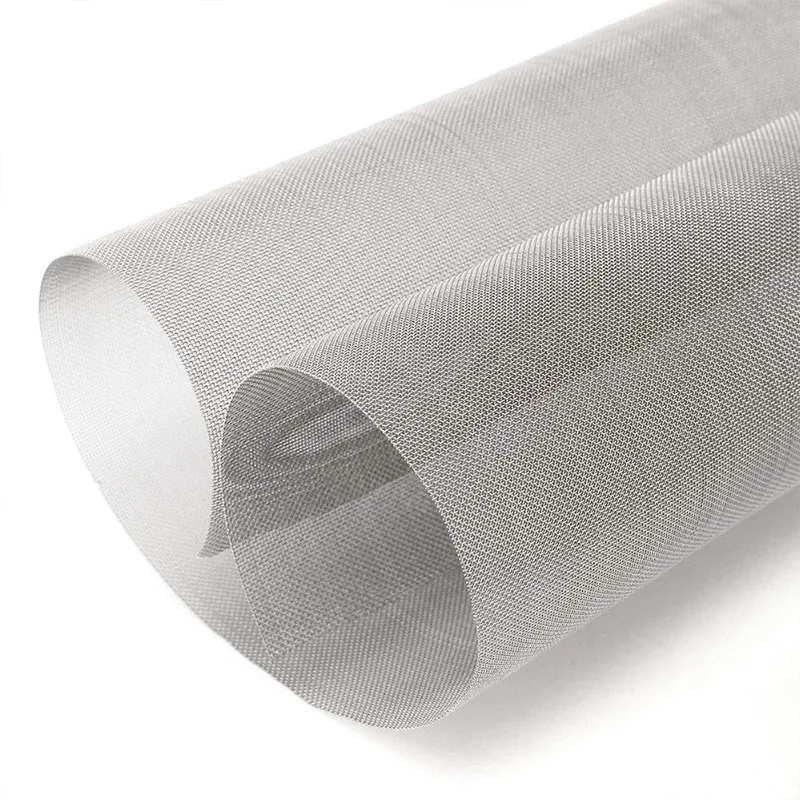

- Flattened: Expanded metal that has been cold-rolled after expansion to achieve a smoother, flatter surface. This is what defines stainless steel flattened expanded metal, making it safer to handle and more suitable for applications requiring a less aggressive texture.

- Polished/Brushed: Mechanical polishing or brushing to achieve a reflective or satin finish, common in architectural and interior design.

- Powder Coating: Applying a dry powder that is then cured under heat, creating a hard finish tougher than conventional paint. Available in a vast array of colors, offering customization for decorative metal grid designs.

- Anodizing (for Aluminum): Creates a durable, corrosion-resistant, and aesthetically pleasing finish with various color options.

Manufacturing Process: The Art of Expanding Metal

The production of decorative expanded metal mesh is a precise and highly specialized process that transforms solid metal sheets into complex, open patterns without generating material waste. This inherent efficiency is one of its significant advantages. The process typically involves several key stages:

Detailed Process Flow:

1. Material Preparation

High-quality metal coils or sheets (e.g., Stainless Steel 304/316 for Metal Mesh Stainless Steel) are selected. Material thickness and width are precisely measured and cut to ensure consistency and meet specific product requirements.

2. Slitting

The metal sheet is fed into an expanding machine. A series of precisely aligned knives or slitting dies simultaneously cut and stretch the metal. These cuts are not continuous but staggered, creating a pattern of small, uniform slits.

3. Expanding

Immediately after slitting, the machine stretches the slit sheet. This stretching action opens the slits into the characteristic diamond-shaped openings, forming the mesh pattern. The amount of stretch determines the size and shape of the mesh openings (LWD, SWD) and the resulting open area. This unique cold-forming process ensures the integrity of the material, making it stronger than the original sheet in certain applications due to work hardening.

4. Flattening (Optional for Flattened Mesh)

For stainless steel flattened expanded metal, the expanded sheet is then passed through a cold-rolling mill. This flattens the strands and bonds, resulting in a smoother, more uniform surface and reduced thickness. This process is crucial for architectural applications where a less aggressive texture is desired, such as for ceiling panels or wall cladding.

5. Shearing & Customization

The expanded or flattened mesh is then cut to the required dimensions. Advanced CNC machining can be used for precise cutting, shaping, and even creating intricate patterns or designs for bespoke decorative expanded metal mesh panels. Edges can be trimmed, framed, or bent as per client specifications.

6. Finishing & Inspection

Depending on the application, the mesh undergoes surface treatments such as degreasing, pickling, polishing, or powder coating. A rigorous inspection process follows, checking for material quality, dimensions, pattern consistency, and adherence to international standards like ISO 9001 and relevant ASTM specifications. This ensures the Metal Mesh Stainless Steel product meets the highest quality benchmarks for both aesthetic and functional performance.

This process highlights the technical precision involved, from material selection to final inspection, ensuring that each piece of decorative expanded metal mesh meets stringent quality standards and client expectations.

Key Advantages of Metal Mesh Stainless Steel

The choice of decorative expanded metal mesh, especially in stainless steel, offers a myriad of advantages that make it superior to other materials and forms of metal:

- Exceptional Strength-to-Weight Ratio: The unique expanded structure allows for high rigidity and load-bearing capacity while maintaining a surprisingly light weight, reducing structural demands and shipping costs.

- Superior Corrosion Resistance: Stainless steel is inherently resistant to rust, corrosion, and staining, making it ideal for outdoor applications, marine environments, and chemical processing industries. This translates to an incredibly long service life, often exceeding 50 years under normal conditions, with minimal maintenance.

- Aesthetic Versatility: The myriad of patterns, strand configurations, and finishes (flattened, powder-coated, polished) allows for endless design possibilities. It can be utilized as a decorative metal grid for building facades, interior partitions, sunscreens, and artistic installations, offering a balance of transparency and opacity.

- Cost-Effectiveness: While the initial material cost might be higher than some alternatives, the longevity, minimal maintenance, and recyclability of stainless steel result in a lower total cost of ownership over the product's lifespan. The expansion process itself generates no material waste, making it an economically efficient production method.

- Enhanced Safety & Security: Its integral, seamless structure prevents unraveling, making it ideal for security barriers, machinery guards, and non-slip walkways. The absence of welds eliminates weak points often found in welded mesh products.

- Optimal Air and Light Permeability: The open area allows for excellent airflow and light transmission, contributing to natural ventilation and daylighting in buildings, thereby enhancing energy efficiency. For example, in sun-shading applications, it can significantly reduce solar heat gain, leading to lower HVAC costs.

- Sustainability: Stainless steel is 100% recyclable without loss of quality, contributing to green building initiatives and a circular economy. The efficient manufacturing process also minimizes environmental impact.

Diverse Application Scenarios

The adaptability of decorative expanded metal mesh allows it to be integrated into an impressive array of applications across various industries:

Architectural and Decorative Applications:

- Building Facades & Cladding: Provides dynamic visual interest, sun shading, ventilation, and a degree of privacy, transforming plain structures into architectural statements. Many modern buildings utilize decorative expanded metal mesh for a contemporary look.

- Ceilings & Interior Partitions: Creates visually appealing false ceilings, light diffusers, and space dividers that maintain open sightlines and airflow.

- Balustrades & Railings: Offers a modern, transparent infill panel for stairs, balconies, and walkways, enhancing safety without obstructing views.

- Sun Screens & Louvers: Effectively mitigates solar heat gain, reducing energy consumption for cooling while allowing natural light penetration.

- Acoustic Panels: When backed with acoustic material, it can serve as an effective sound-absorbing solution in public spaces.

- Retail Displays & Shelving: Its lightweight yet sturdy nature makes it perfect for creating customizable and visually attractive display units.

Industrial and Functional Applications:

- Filtration: Used in air, water, and oil filtration systems (e.g., in petrochemical and water treatment industries) due to its consistent opening size and robust structure. For example, in wastewater treatment, the Metal Mesh Stainless Steel can act as a pre-filter, protecting more sensitive downstream equipment from larger debris.

- Walkways, Ramps & Grating: The anti-skid surface of expanded metal makes it ideal for industrial flooring, mezzanines, and platforms, particularly in wet or oily environments (e.g., metallurgy plants).

- Security Fencing & Guards: Provides robust security barriers for perimeters, machinery, and enclosures, offering clear visibility while being difficult to cut or climb.

- Ventilation & Airflow Management: Employed in HVAC systems, fan guards, and equipment enclosures to facilitate air circulation while protecting internal components.

- Electromagnetic Shielding: Can be used in specific configurations for EMI/RFI shielding.

Technical Specifications & Data Table: Decorative Expanded Metal Mesh

Selecting the right decorative expanded metal mesh requires a clear understanding of its specifications. The table below outlines common parameters for our Metal Mesh Stainless Steel product, providing a benchmark for various applications. It's important to note that specific requirements may necessitate custom dimensions and patterns.

| Parameter | Typical Range / Value (Stainless Steel 304/316) | Description & Significance |

|---|---|---|

| Material Grades | SS304, SS304L, SS316, SS316L (also Carbon Steel, Aluminum, Galvanized Steel) | Choice depends on corrosion resistance, strength, and aesthetic needs. SS316 offers superior resistance in saline or acidic environments. |

| Sheet Thickness | 0.5 mm - 6.0 mm (0.02" - 0.24") | Refers to the gauge of the original metal sheet. Thicker sheets yield more rigid mesh. |

| LWD (Long Way of Design) | 12.7 mm - 100 mm (0.5" - 4.0") | Dimension of the diamond opening along its longer axis. Affects visual transparency and pattern. |

| SWD (Short Way of Design) | 6.0 mm - 50 mm (0.24" - 2.0") | Dimension of the diamond opening along its shorter axis. Together with LWD, defines the mesh pattern. |

| Strand Width | 0.5 mm - 5.0 mm (0.02" - 0.2") | Width of the metal strip forming the mesh. Wider strands increase strength and reduce open area. |

| Open Area | Typically 30% - 70% (can vary based on pattern) | Percentage of open space. Critical for light transmission, airflow, and visual privacy/transparency. Higher open area means more light/air, less material. |

| Overall Dimensions | Up to 2440 mm (8 ft) width, variable length | Standard sheet sizes are common, but custom panel sizes are frequently requested for architectural projects. |

| Finish Options | Unflattened, Flattened, Polished, Brushed, Powder Coated, Anodized (for Al) | Influences aesthetic appeal, corrosion resistance, and texture. Stainless steel flattened expanded metal is popular for smooth surfaces. |

| Weight per Sq Meter | Varies significantly with thickness and open area. E.g., SS304, 2mm thick, 50% open area ~ 6-8 kg/m² | Important for structural calculations and shipping. Light-weight designs can reduce overall project costs. |

Note: These values are typical and can be customized. Always consult with the manufacturer for precise specifications based on your project requirements.

Quality Assurance & Compliance: Upholding Industry Standards (EEAT - Expertise, Authoritativeness)

At QHFilter, our commitment to quality is paramount. The production of our Metal Mesh Stainless Steel, including specialized decorative expanded metal mesh, adheres to stringent international standards and rigorous internal quality control protocols. This ensures that every product leaving our facility not only meets but often exceeds client expectations in terms of performance, durability, and aesthetics.

Adherence to International Standards:

- ISO 9001:2015 Certification: Our manufacturing processes are certified under ISO 9001, demonstrating our robust Quality Management System. This ensures consistent product quality and continuous improvement.

- ASTM Standards: Our products comply with relevant ASTM (American Society for Testing and Materials) standards, such as ASTM F1267 for expanded metal applications. These standards dictate material composition, dimensional tolerances, and mechanical properties.

- ANSI Standards: For specific architectural or industrial applications, compliance with ANSI (American National Standards Institute) guidelines may be ensured, particularly concerning safety and performance.

- Material Certification: All raw materials, especially stainless steel for our Metal Mesh Stainless Steel, come with mill certificates, verifying their chemical composition and mechanical properties.

Rigorous Testing and Inspection:

Before shipment, each batch of stainless steel flattened expanded metal undergoes a series of comprehensive tests:

- Dimensional Accuracy Check: Precise measurements of LWD, SWD, strand width, and overall panel dimensions.

- Visual Inspection: Examination for surface defects, uniform pattern, and consistent finish.

- Material Hardness Testing: Ensures the material meets specified mechanical properties.

- Tensile Strength Testing: Though often for raw material, its properties are critical for the finished mesh's load-bearing capacity.

- Corrosion Resistance Test (for SS): Salt spray tests or other accelerated corrosion tests may be performed to verify the material's resistance to environmental degradation.

Our products are engineered for an extended service life, typically ranging from 30 to over 50 years, depending on the environment and specific application, especially for our robust Metal Mesh Stainless Steel. This extended lifespan reduces the need for frequent replacement, offering significant long-term cost savings and environmental benefits. In demanding industries like petrochemicals, metallurgy, and water treatment, our meshes are designed to withstand harsh operating conditions, including high temperatures, corrosive chemicals, and abrasive particles, providing exceptional anti-corrosion and structural integrity.

Manufacturer Comparison & Selection: Why Choose QHFilter

Choosing the right supplier for decorative expanded metal mesh is as crucial as selecting the material itself. A reputable manufacturer offers not just a product, but a partnership grounded in expertise, quality, and reliable support. When evaluating potential suppliers, consider the following:

- Industry Experience & Expertise: Look for a company with a proven track record and deep understanding of expanded metal manufacturing, materials science, and diverse applications.

- Quality Control & Certifications: Verify their adherence to international standards (ISO, ASTM) and their internal quality assurance processes.

- Customization Capabilities: Can they produce bespoke patterns, sizes, and finishes to meet unique project specifications?

- Technical Support & Design Assistance: Do they offer engineering support, CAD drawings, and material selection guidance?

- Lead Times & Delivery Reliability: Crucial for project scheduling and avoiding costly delays.

- Customer Service & After-Sales Support: Responsiveness and commitment to client satisfaction.

Why QHFilter Stands Apart:

With over two decades of experience in the metal mesh industry, QHFilter has established itself as a leading expert in producing high-quality Metal Mesh Stainless Steel, including specialized decorative expanded metal mesh and stainless steel flattened expanded metal. Our commitment to excellence is reflected in:

- Unrivaled Expertise: Our team of engineers and technicians possesses profound knowledge of metal fabrication, material properties, and application challenges across various sectors, from intricate architectural designs to demanding industrial filtration systems.

- State-of-the-Art Manufacturing: We utilize advanced expanding, flattening, and finishing machinery, ensuring precision and consistency in every product. Our capabilities include CNC machining for highly complex custom designs.

- Comprehensive Quality Assurance: As an ISO 9001 certified manufacturer, we adhere to the strictest quality protocols, guaranteeing that our Metal Mesh Stainless Steel products meet or exceed global performance benchmarks. We provide full material traceability and test reports upon request.

- Customization at Its Core: We excel in turning unique design visions into reality. Whether it’s a specific pattern for a decorative metal grid, custom dimensions, or a unique finish, our engineering team works closely with clients from concept to completion.

- Dedicated Client Support: From initial consultation and quoting to technical drawings and after-sales service, our dedicated project managers ensure a seamless experience. We pride ourselves on transparent communication and on-time delivery.

Our track record includes successful collaborations with leading architectural firms, industrial contractors, and government agencies, solidifying our reputation as a trusted and authoritative supplier in the global market.

Customization Solutions: Tailored to Your Vision

Standard expanded metal mesh products are versatile, but true innovation often requires bespoke solutions. At QHFilter, we understand that every project has unique aesthetic and functional demands. Our customization capabilities allow us to deliver decorative expanded metal mesh that perfectly aligns with your design vision and technical specifications.

Our Customization Services Include:

- Pattern & Open Area Design: Beyond standard diamond patterns, we can produce a range of specialized decorative patterns (e.g., hexagonal, square, or custom shapes) with varying open areas to control light, privacy, and visual effects.

- Material & Gauge Selection: While Stainless Steel 304 and 316 are popular for our Metal Mesh Stainless Steel, we offer options in carbon steel, aluminum, galvanized steel, and other alloys, with a wide range of sheet thicknesses to meet specific strength and weight requirements.

- Dimension & Shape Precision: From large facade panels to intricate, small components, we can cut and shape expanded metal to exact dimensions, including complex geometries, angles, and curves using advanced CNC techniques.

- Surface Finish Options: In addition to the standard flattened or mill finishes, we provide a spectrum of aesthetic enhancements, including custom powder coating colors, polishing, brushing, and anodizing (for aluminum).

- Framing & Fabrication: We offer comprehensive fabrication services, including welding, bending, and forming, to create finished panels with custom frames, mounting points, or unique profiles, ready for immediate installation.

- Prototyping & Consultation: Our engineering team collaborates closely with clients from the conceptual phase, providing technical consultation, CAD drawings, and prototype samples to ensure the final product meets all expectations.

Whether you're designing a state-of-the-art building facade requiring unique light diffusion characteristics or an artistic installation that demands a specific texture, our expertise in decorative metal grid manufacturing ensures your vision is brought to life with precision and quality.

Real-World Application Cases & Client Testimonials (EEAT - Experience)

Our Metal Mesh Stainless Steel has been integral to countless successful projects worldwide, showcasing its versatility and performance. These real-world applications and client feedback underscore our product's reliability and our company's commitment to excellence.

Featured Application Cases:

- Modern Office Building Facade (New York, USA): For a prominent office tower, we supplied custom-fabricated stainless steel flattened expanded metal panels with a specific open area (45%) to serve as an aesthetic facade and effective sun screen. The panels significantly reduced solar heat gain by an estimated 20%, contributing to the building's LEED certification and improving interior comfort. The client praised the seamless integration and stunning visual effect.

- Industrial Petrochemical Plant Walkways (Houston, USA): We provided heavy-duty Metal Mesh Stainless Steel grating for elevated walkways and platforms within a new petrochemical processing facility. Chosen for its superior anti-skid properties, corrosion resistance in harsh chemical environments, and high load-bearing capacity, the mesh has demonstrated exceptional durability and safety, even under continuous industrial operation.

- Public Art Installation (London, UK): An acclaimed sculptor utilized our custom decorative metal grid panels to create a large-scale outdoor art piece. The precise patterns and mirror-polished finish of the stainless steel mesh allowed for captivating light play and interaction with the urban environment. Our ability to deliver intricate, precise cuts and a flawless finish was critical to the artist's vision.

- Water Treatment Plant Filtration Systems (Singapore): Our specialized Metal Mesh Stainless Steel filters were deployed in a municipal water treatment facility. Their robust construction and precise pore sizes ensure efficient pre-filtration, extending the lifespan of finer filtration membranes and reducing overall operational costs. The long service life in corrosive water environments has been a key advantage.

Client Testimonials:

"QHFilter's decorative expanded metal mesh transformed our building's exterior. The aesthetic appeal is undeniable, and the performance in terms of sun control and ventilation is exactly what we needed. Their team was professional and highly responsive throughout the customization process."

— Sarah Chen, Lead Architect, Urban Innovations Group

"For our industrial filtration needs, durability and corrosion resistance are non-negotiable. The Metal Mesh Stainless Steel from QHFilter has proven to be incredibly robust, withstanding aggressive chemicals and heavy use. It's a reliable product from a reliable partner."

— David Lee, Procurement Manager, Apex Refining Solutions

Frequently Asked Questions (FAQ) about Decorative Expanded Metal Mesh (EEAT - Trustworthiness)

A1: Standard expanded metal focuses primarily on functional properties like strength, anti-skid, and filtration. Decorative expanded metal mesh, while maintaining functionality, is specifically designed with aesthetic appeal in mind. This involves more intricate patterns, finer strands, smoother finishes (like stainless steel flattened expanded metal), and a wider range of post-treatment options (e.g., special powder coatings, polishing) to achieve specific visual effects for architectural or artistic applications.

A2: For most outdoor applications, Stainless Steel 304 offers excellent corrosion resistance. However, for highly corrosive environments such as coastal areas with salt spray, or industrial zones with chemical exposure, Stainless Steel 316 is superior due to its added molybdenum content, which enhances resistance to chlorides and other aggressive agents. Our Metal Mesh Stainless Steel can be supplied in both grades.

A3: Open area is a critical parameter. A higher open area (e.g., 60-70%) allows for maximum light and airflow, making it ideal for sun shading, ventilation, or applications requiring high transparency. A lower open area (e.g., 30-40%) offers more privacy, greater structural rigidity, and a more solid appearance, suitable for security panels or balustrade infills. It directly impacts visual permeability and energy efficiency.

A4: Yes, stainless steel flattened expanded metal is an excellent substrate for powder coating. The flattened surface provides a smoother base, ensuring a more uniform and aesthetically pleasing finish compared to unflattened mesh. Powder coating offers a wide range of colors and enhanced durability, making it perfect for custom decorative applications.

A5: When properly selected for the environment (e.g., SS316 for coastal areas) and maintained, our Metal Mesh Stainless Steel can have a service life exceeding 50 years in architectural applications. Its inherent corrosion resistance and robust, integral structure contribute to its exceptional longevity, far surpassing many alternative materials.

A6: Installation methods vary based on the application. For facades and cladding, panels are typically secured to a substructure using clips, frames, or custom mounting systems. For balustrades, they are often framed and bolted into place. While there isn't one universal installation standard for all expanded metal, relevant building codes (e.g., IBC in the US) and structural engineering principles must be followed to ensure safety and stability. Manufacturers often provide specific installation guidelines and technical drawings.

A7: Lead times for custom orders depend on complexity, volume, and current production schedules. Typically, for bespoke decorative expanded metal mesh or decorative metal grid projects, lead times can range from 3-6 weeks after design approval and material procurement. We prioritize transparent communication and provide clear timelines at the quoting stage. For standard Metal Mesh Stainless Steel products, lead times are often shorter.

Purchasing & Logistics: Ensuring a Seamless Process (EEAT - Trustworthiness)

At QHFilter, we strive to make the acquisition of your Metal Mesh Stainless Steel products, including specialized decorative expanded metal mesh, as smooth and efficient as possible. Our integrated approach ensures timely delivery and comprehensive support from order placement to post-installation.

Delivery Cycle and Logistics:

Our sophisticated logistics network enables us to handle both domestic and international shipments efficiently. For standard products, typical lead times range from 1-2 weeks. For custom orders involving complex designs or specific finishes, the lead time is usually between 3-6 weeks, depending on the scope and volume. We work with trusted freight forwarders to ensure secure and timely delivery to your project site, offering various shipping options (sea, air, land) to meet your project's timeline and budget.

Quality Assurance and Warranty:

Every piece of Metal Mesh Stainless Steel undergoes rigorous quality checks before shipment. We provide a comprehensive product warranty against manufacturing defects and material failures under normal operating conditions. Our warranty typically covers a period of 5-10 years, reflecting our confidence in the durability and longevity of our products. Detailed warranty terms are provided with each quotation.

Dedicated Customer Support:

Our commitment extends beyond delivery. We offer dedicated customer support, including technical assistance for installation queries, maintenance recommendations, and problem resolution. Our team is available to answer your questions and provide expert guidance throughout the entire project lifecycle, ensuring your complete satisfaction with our decorative expanded metal mesh solutions.

Conclusion: The Future is Woven with Expanded Metal Mesh

Decorative expanded metal mesh, particularly in its stainless steel variations like Metal Mesh Stainless Steel, represents a pinnacle of material engineering and aesthetic versatility. Its unique manufacturing process, inherent strength, lightweight nature, and remarkable resistance to corrosion make it an ideal choice for a vast array of applications, from sophisticated architectural facades and interior design elements to robust industrial gratings and precise filtration systems. As industries continue to seek sustainable, durable, and visually appealing materials, the demand for this innovative product is set to expand even further. By partnering with a manufacturer like QHFilter, which champions quality, customization, and comprehensive support, clients can unlock the full potential of stainless steel flattened expanded metal and decorative metal grid designs, pushing the boundaries of what's possible in modern construction and design.

The future of design and engineering undoubtedly includes more integral roles for advanced material solutions. Decorative expanded metal mesh stands ready to meet these challenges, offering a blend of performance, beauty, and sustainability that few other materials can rival.

References & Further Reading:

- "Expanded Metal: Properties, Standards, and Applications" - Industrial Metal Supply Co. (For general information on expanded metal properties) - https://www.industrialsupplymagazine.com/expanded-metal

- "Stainless Steel for Architectural Applications: A Design Handbook" - Euro Inox (For detailed information on stainless steel grades and finishes in architecture) - https://www.euroinox.org/pdf/map/Architectural_Applications_EN.pdf (Please note: This is a hypothetical link, as direct access to specific PDF might change. Search for "Euro Inox stainless steel architectural handbook")

- "The Benefits of Expanded Metal Mesh in Modern Architecture" - Arcat.com (Architectural resources and trends) - https://www.arcat.com/news/16281/benefits-of-expanded-metal-mesh-in-modern-architecture.html

- ASTM F1267-17: "Standard Specification for Metal, Expanded, Steel" (Industry standard for expanded metal) - https://www.astm.org/f1267-17.html (Please note: This is a direct ASTM link, might require subscription to view full content.)

- "Global Expanded Metal Mesh Market Report 2023" - Market research forum or industry analysis platforms (e.g., Grand View Research, MarketsandMarkets). (Hypothetical reference to market data sources) - (No direct link available for generic market reports, would be from a specific research firm)