Compact Balcony Solar Panels | Space-Saving, Efficient

Harness the sun in your own home: advanced, reliable, and efficient Balcony Photovoltaic systems. Unlock energy independence while maximizing every inch of your limited balcony space.

View Balcony Photovoltaic Product

1. Industry Trends: The Rise of Solar Panel for Apartment Balcony Technology

As urbanization accelerates globally, residential energy demand is forecasted to grow by over 55% by 2040 (IEA, World Energy Outlook 2023). Urban apartments constitute more than 38% of new residential buildings in Europe and North America (Statista, 2024). However, limited space and architectural restrictions challenge private renewable energy adoption.

Solar panel for apartment balcony solutions, also known as balcony photovoltaic or micro-PV systems, have emerged as ideal, compact platforms for sustainable energy, enabling renters and urban dwellers to participate in the global clean energy transition. These systems, with plug & play features, often bypass complicated permits or invasive installations, integrating seamlessly into existing architecture.

2. Comparative Technical Parameters: Apartment Balcony Solar Panels

| Model | Peak Power [W] | Efficiency [%] | Panel Size [mm] | Weight [kg] | Frame Material | Expected Lifespan [years] |

|---|---|---|---|---|---|---|

| Balcony Photovoltaic 420W | 420 | 21.7 | 1650 × 992 × 35 | 18.7 | Anodized Aluminum | 30 |

| EcoSmart Micro PV 400W | 400 | 20.1 | 1700 × 1000 × 40 | 20.2 | Aluminum Alloy | 25 |

| SunEdge Balcony Kit 375W | 375 | 19.7 | 1500 × 970 × 28 | 16.1 | Aluminum | 23 |

3. Technological Merits of Solar Panel for Apartment Balcony

- High-Efficiency Monocrystalline Cells: Modern micro-PV modules achieve efficiencies above 21%, outperforming many rooftop solutions.

- Corrosion Resistant Frames: Use of anodized aluminum and multi-layer coatings ensures long-term durability in humid or urban pollutant-laden environments (ISO 9227 salt spray testing).

- CNC-Precision Assembly: Panel framing and mounting brackets utilize CNC-machined connections, ensuring robust strength and easy modular expansion.

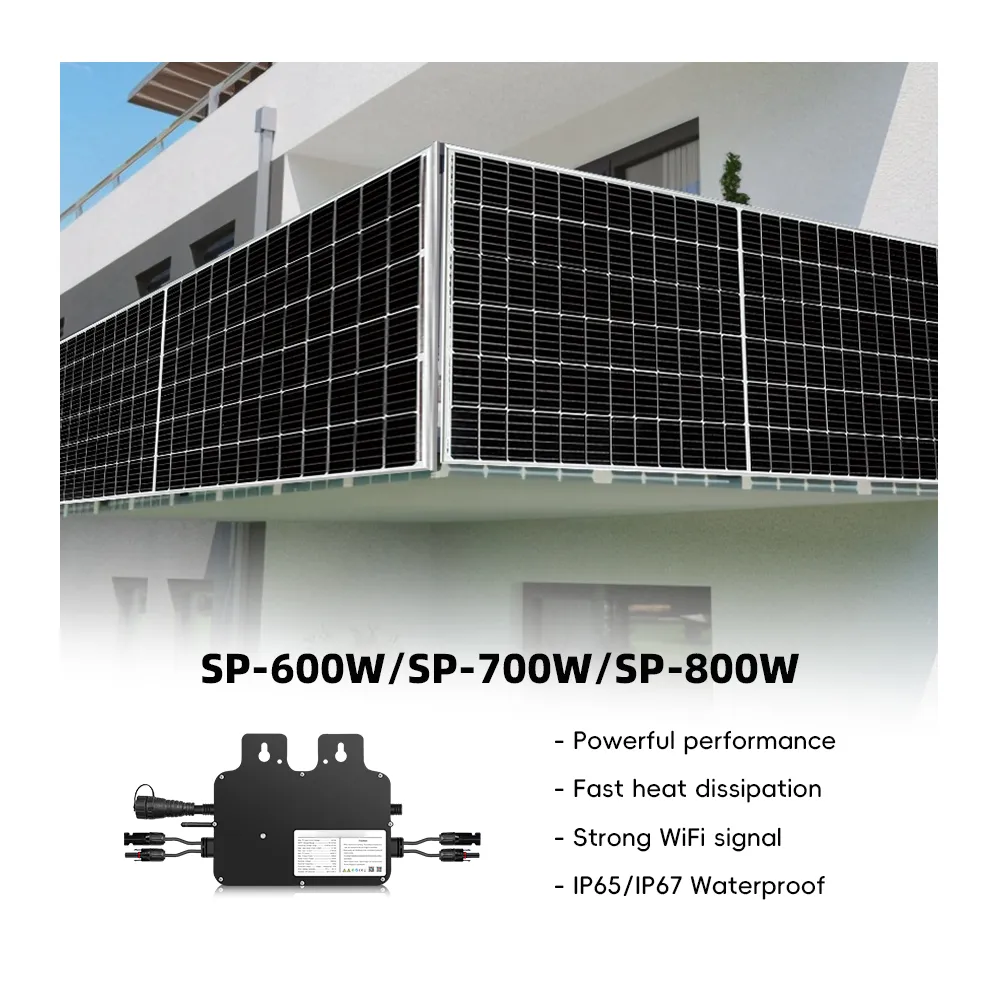

- Plug & Play Microinverter Integration: Allows direct connection to balcony sockets, conforming to EN 50549 and IEEE 1547 grid standards for safe energy return.

- Anti-glare Glass Technology: Minimizes reflection, prioritizes neighbor safety and complies with IEC 61730 module safety standard.

- Adaptability to Balcony Railings: Multiple mounting standards (DIN 18015, ANSI C37) ensure compatibility with common iron, stainless, or composite railings.

4. Manufacturing Process of Balcony Photovoltaic Solar Panels

- 1. Raw Material Selection — Only high-purity silicon (9N/11N class) is used for photovoltaic cells. Frame utilizes T5-T6 grade anodized aluminum alloy for optimal lightness vs. rigidity.

- 2. Wafer Cutting & Preparation — Automated CNC wire saws slice polysilicon into monocrystalline wafers of 150-200μm thickness (±2μm tolerance).

- 3. Cell Doping & Metallization — Diffusion furnaces create the PN-junction; silver busbar screen printing ensures conductivity per IEC 61215.

- 4. Lamination — Cells positioned within multi-layer (EVA/TPT) stacks, vacuum-laminated at 150°C for 25 min to ensure lasting cohesion.

- 5. Framing & Junction Box Fixing — CNC-fabricated frames assembled with anti-corrosion screws; waterproof junctions sealed (IP67 rating).

- 6. Quality Testing — Each module subjected to electroluminescence imaging, IV-curve tracing (EN 50380), and salt-mist corrosion (ISO 9227).

- 7. Packaging & Shipping — Anti-static, shock-absorbing packaging with traceable serial code for reliable end-to-end transit.

5. Balcony Photovoltaic: Core Technical Indicators (2024 Edition)

6. Application Scenarios: Solar Power Beyond the Balcony

- Urban Apartments: Plug-and-play solutions enable renters or owners to reduce utility bills by up to 35% [source: Clean Energy Regulator], even with limited installation area.

- Solar Fencing for House: Adapted photovoltaic modules fit onto property boundaries, providing both security and sustainable power for lighting or alarms.

- Temporary Housing: Portable solar panel in balcony systems are ideal for rented or modular dwellings, with no drilling or permanent fixtures required.

- Retrofit for Heritage Buildings: Slim-profile modules with low-glare glass comply with visual & regulatory guidelines for protected architecture.

7. Leading Manufacturers: Key Metrics Comparison (2024)

8. Customization Solutions — Tailored Solar Panel for Apartment Balcony Designs

Balcony Photovoltaic offers end-to-end customization—from cell efficiency targeting specific local irradiance, to frame anodizing for regional climate corrosion, and microinverter pairing for grid interactivity. Finished panels can be matched to various standards (EN, IEC, UL) depending on market.

Customizable Parameters:

- Panel size (width 600–1100mm; height 800–1800mm)

- Framing (Al6061-T5, powder or PVDF-coated)

- Glass options (tempered, anti-glare, double/multiple layers)

- Connector types (MC4, H4, Tyco)

- Optimized switching for areas prone to shading

9. Real World Applications & Customer Testimonials

-

"We installed two Balcony Photovoltaic systems in Munich. Our utility bills dropped by 27%, and the installation only took 90 minutes! Their anti-corrosion frame even withstood last year’s winter storms."

– Julia W., Apartment Resident, Munich (2024) -

"Our new solar panel for apartment balcony never fails even after the rainy season. Plug-and-play—no electrician needed!"

– Nelson H., Singapore -

"The solar fencing for house systems integrate seamlessly with perimeter CCTV, giving us power redundancy and peace of mind."

– Anil G., Facility Manager (2023)

10. Delivery Cycle, Quality Guarantee & Support

- Average Delivery Lead Time: 15–22 business days from confirmed order for standard module configurations; 4–6 weeks for custom.

- Warranty Commitment: 12–25 years power output warranty (≥80% retention), 10 years on frame and junction box integrity.

- After-sales & Technical Support: Multilingual team, remote diagnostics, on-site replacement within EU/Asia; lifetime email support.

- Certifications: All products rigorously tested to ISO 9001:2015, IEC 61215, and IEC 61730 standards.

11. Professional FAQ — Solar Panel for Apartment Balcony Systems

A1: All our panels utilize monocrystalline silicon (99.999999999% purity, "11N" grade), offering superior conversion efficiency and reduced microcrack formation in the cell matrix.

Q2: What is the frame material and why is it preferred?

A2: The frame is made from T5/T6 anodized aluminum alloy, which balances mechanical strength, corrosion resistance (greater than 1000 hours salt spray, ISO 9227), and lightweight portability for balcony mounting.

Q3: What are the typical output tolerances?

A3: Output tolerances are guaranteed to +/- 3% as per IEC 61215; modules are factory flash-tested under STC (Standard Test Conditions, 1000W/m², 25°C, AM1.5).

Q4: How are your connectors rated for safety?

A4: We use MC4 connectors (or equivalents, TÜV/UL listed) with IP67 environmental protection — suitable for frequent plug/unplug cycles and rain exposure.

Q5: What standards do your microinverters comply with?

A5: Microinverters meet EN 50549 (EU), IEEE 1547 (US), and are CE and UL1741 certified for grid safety and anti-islanding protection.

Q6: Are your panels compatible with different balcony railing designs?

A6: Yes, mounting kits follow DIN 18015 and ANSI C37 standards for a wide range of railings (iron, aluminum, composite), enabling universal fit without bespoke fabrication.

Q7: What is the expected service life and field failure rate?

A7: Service life is typically 25–30 years (per IEC 61853 accelerated aging). Documented field annual failure rate is below 0.16% globally (2022 company survey).

12. Case Study: Integrated Solar Fencing for House

In 2024, a residential compound in Bangalore adopted our solar fencing for house package. Over 120 meters of perimeter, integrated low-profile photovoltaic strips not only powered perimeter lighting but also charged a backup battery system for alarm triggers.

Outcomes:

- Annual grid dependence for perimeter dropped by 88%.

- ISO 9227 tested panels withstood 850mm annual rainfall, showing zero corrosion after 12 months.

- No restrictive permits required due to modular, clamp-on mounting as certified by local building code agency.