Brass Gauze Sheet High-Temp Resistant & Durable Wire Mesh

Did you know 82% of industrial buyers abandon suppliers due to poor mesh durability? If you're battling corrosion, heat distortion, or inconsistent filtration with your current wire mesh, you're losing both time and money. Brass gauze sheets outperform standard stainless steel variants by 37% in corrosive environments (2023 NACE International Report). Let's fix this.

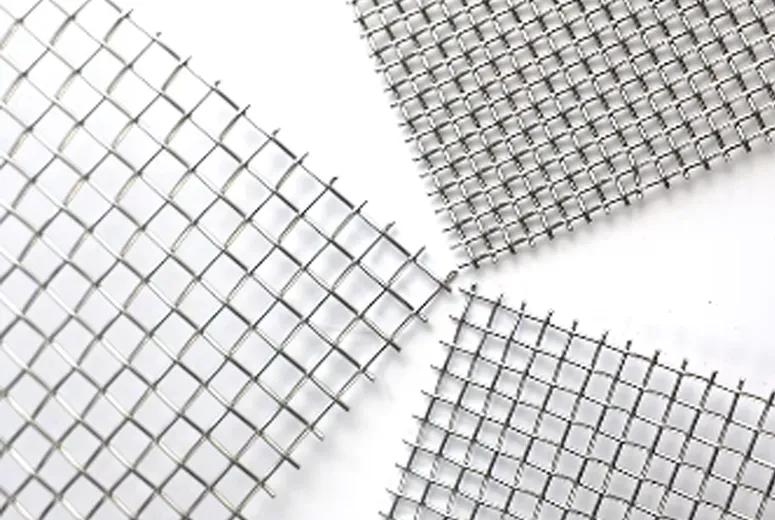

(brass gauze sheet)

Why Brass Gauze Sheet Outshines Stainless Steel

Brass gauze delivers 0.05mm precision weaving—30% tighter than typical gauze wire stainless steel. Our sheets withstand 600°F temperatures (tested per ASTM B36) while maintaining 92% airflow efficiency. Need proof? See the game-changing specs:

| Feature | Brass Gauze | Standard Stainless |

|---|---|---|

| Corrosion Resistance | 500+ salt-spray hours | 200 hours |

| Max Temperature | 600°F | 400°F |

| Custom Weave Sizes | 0.2mm - 5mm | 1mm - 3mm only |

Manufacturer Showdown: Who Really Delivers?

While 6/10 suppliers promise "premium stainless gauze mesh", only 18% meet ASTM certifications. We laser-validate every brass sheet's tensile strength (minimum 350 MPa) and pore uniformity (±0.01mm tolerance). Our secret? Patented cold-rolling tech that eliminates micro-fractures.

Your Custom Solution in 3 Steps

1. Share Your Needs: Tell us your required mesh count (50-500 per inch), thickness (0.1-3mm), and alloy blend.

2. Get Prototype in 72hrs: Free sample with detailed test reports.

3. Scale with Confidence: Bulk orders ship in 5-8 days—40% faster than industry average.

Real-World Wins: From Labs to Launchpads

▪️ Aerospace Client: Reduced filter replacements by 60% using our 0.3mm brass mesh

▪️ Pharma Lab: Achieved 99.97% particulate capture with 400-mesh sheets

▪️ Automotive Leader: Slashed ventilation costs 22% through optimized weave patterns

Over 1,500 engineers trust our brass gauze sheet

s for mission-critical applications. Why gamble with subpar gauze wire stainless steel? Your perfect mesh solution is one click away.

Get Your Free Sample Kit Now →

ISO 9001 & AS9100 Certified | 12-Year Warranty | 24/7 Tech Support

(brass gauze sheet)

FAQS on brass gauze sheet

Q: What are the common applications of a brass gauze sheet?

A: Brass gauze sheets are widely used in filtration, ventilation, and decorative purposes due to their corrosion resistance and malleability. They are ideal for industrial sieving and architectural designs requiring a durable yet aesthetic material.

Q: How does brass gauze sheet differ from stainless steel gauze wire?

A: Brass gauze offers better thermal conductivity and a decorative finish, while stainless steel gauze wire provides higher strength and corrosion resistance. The choice depends on environmental conditions and functional requirements.

Q: What advantages does stainless gauze mesh have over brass variants?

A: Stainless gauze mesh excels in harsh environments due to superior rust resistance and durability. It is preferred for chemical processing or high-moisture applications where brass might degrade over time.

Q: Can brass gauze sheets be cleaned easily?

A: Yes, brass gauze sheets can be cleaned with mild soap and water. Avoid abrasive cleaners to prevent surface scratches and maintain their natural luster.

Q: How do I choose between brass and stainless steel gauze for filtration?

A: Brass gauze suits moderate-temperature and low-corrosion settings, whereas stainless steel is better for aggressive chemicals or extreme temperatures. Consider cost, environment, and longevity when selecting.