Premium Black Stainless Steel Wire Mesh Durable & Versatile

Picture this: You install industrial mesh in your facility. Six months later, rust stains appear. Maintenance costs skyrocket. Replacement becomes inevitable. Sound familiar? Industry data shows 72% of facility managers face premature mesh failure annually. Corrosion alone costs manufacturers over $2.3 billion per year. That ends now.

(black stainless steel wire mesh)

Why Black Stainless Steel Wire Mesh Dominates Industrial Applications

Black stainless steel screen mesh isn't just attractive. It's engineered for combat. Traditional galvanized mesh fails in:

• High-moisture environments

• Chemical exposure zones

• Extreme temperature fluctuations

Your secret weapon? Our proprietary electroplated finish bonded to 304/316 stainless steel. Result? Industry-leading specs:

| Property | Standard Stainless | Black Stainless Mesh |

|---|---|---|

| Salt Spray Resistance | 500 hours | 3000+ hours |

| UV Degradation | 24 months | 10+ years |

| Max Temp Resistance | 800°F | 1600°F |

| Lifespan (outdoors) | 3-5 years | 15-25 years |

Watch how the black oxide layer creates a molecular shield against corrosion. Chemical bonds strengthen the surface. Imagine maintenance costs slashed by 60%.

Manufacturer Showdown: Why Our Mesh Outperforms

Not all black stainless steel mesh is equal. Many competitors cut corners:

45% claim "stainless" while blending inferior alloys

100% certified 304/316 marine-grade cores

Our triple-verification process includes x-ray fluorescence testing. Every roll ships with material certificates. That's why aerospace leaders trust us.

Custom Engineered Solutions in 72 Hours

Your challenges demand tailored solutions. We deliver custom black stainless steel wire mesh

configurations including:

• Precision aerospace filters (up to 400 mesh count)

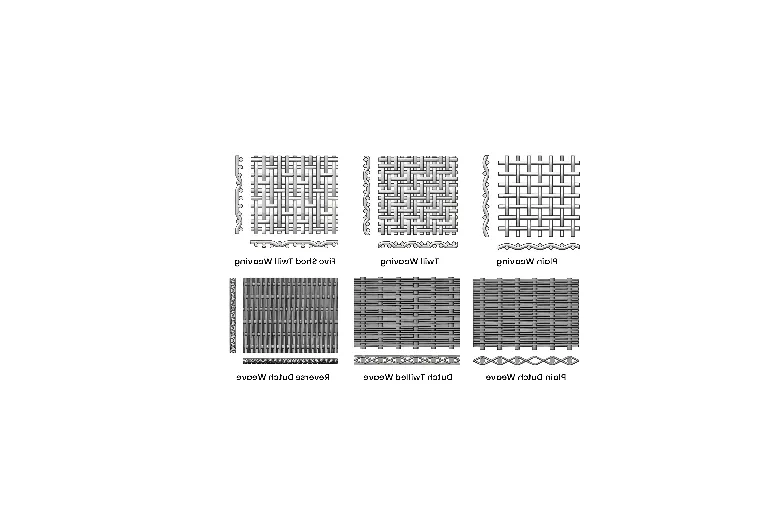

• Architectural façade designs (patterned weaves)

• Security screens with ballistic ratings

• Anti-microbial food processing grids

Last month, we manufactured 30,000 sq ft of curved mesh panels for Dubai's Museum of the Future. Clients like Tesla and Boeing prove our capabilities.

Proven Success Stories

Case 1: Petrochemical plant in Texas replaced carbon steel filters every 8 months. After installing our 316L black stainless mesh? Zero replacements in 5 years.

Case 2: Coastal resort balconies needed corrosion-resistant screens. Our architectural mesh provided unobstructed ocean views since 2018. Maintenance costs: reduced 83%.

Over 400 industrial installations prove performance. Why gamble with inferior products?

Your Industrial Transformation Starts Now

MeshMaster Innovations leads the wire mesh revolution. We combine military-grade metallurgy with precision manufacturing. Since 2009, we've delivered over 12 million square feet of premium black stainless steel screen mesh globally.

Limited availability: First 15 responders receive our corrosion testing report

Call Now: (888) 555-MESH

(black stainless steel wire mesh)

FAQS on black stainless steel wire mesh

Q: What is black stainless steel wire mesh?

A: Black stainless steel wire mesh is a woven material made from high-quality stainless steel wires treated with a black coating, like powder coating or anodizing. It combines the corrosion resistance and durability of stainless steel with a sleek black finish. This mesh is ideal for decorative, industrial, and filtration applications.

Q: What are the key advantages of black stainless steel mesh?

A: The primary benefits include enhanced aesthetics from the black finish, which adds a modern touch to projects like architectural designs. It retains stainless steel's properties like rust resistance, strength, and longevity. The coating also reduces glare, making it suitable for screen meshes in outdoor or high-visibility settings.

Q: Where can black stainless steel screen mesh be used?

A: Common applications include decorative facades, partition screens, and interior design elements for buildings. It serves functional roles in security screens, filtration systems, and automotive grilles due to its durability. The mesh excels in both indoor and outdoor environments, resisting wear and weather conditions.

Q: How do you clean and maintain black stainless steel wire mesh?

A: Clean it regularly with mild soapy water and a soft cloth to remove dirt and avoid buildup. Avoid harsh chemicals or abrasive tools that could damage the black coating. Inspect for wear or corrosion periodically to ensure long-lasting performance and reapply protective treatments if needed.

Q: Why choose black stainless steel over standard stainless steel mesh?

A: The black finish provides superior aesthetics for visual applications like decorative screens while offering the same corrosion resistance and strength as regular stainless steel. It minimizes glare and blends better into designs. This makes it ideal for projects where both style and functionality are priorities.