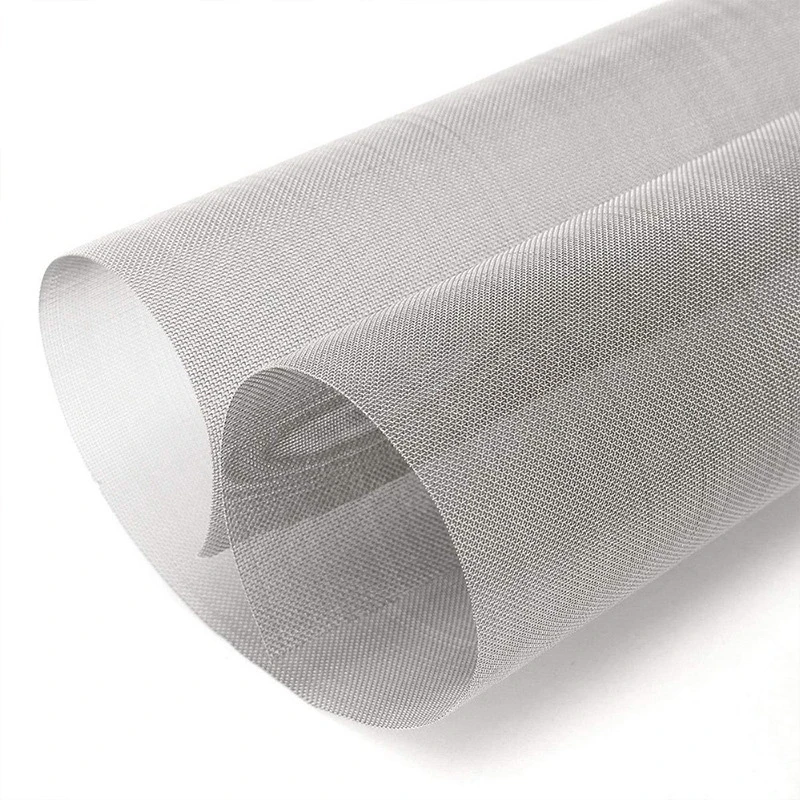

904L Stainless Steel Sintered Wire Mesh High-Temp & Corrosion Resistant

Did you know 68% of industrial equipment failures stem from material corrosion? In harsh environments like chemical plants or offshore rigs, your wire mesh filters face extreme pressures. Standard 316L stainless steel lasts just 2-3 years in seawater - but 904L sintered wire mesh delivers 5X longer service life. Read how this game-changing material solves your toughest filtration challenges.

(904l stainless steel sintered wire mesh)

Technical Superiority: 904L vs Standard Steel Alloys

904L sintered wire mesh brings 25% higher molybdenum content than 316L. This means:

- ✓ Chloride resistance up to 10,000 ppm

- ✓ Operating temps reaching 450°F (232°C)

- ✓ Pore sizes from 0.5μm to 100μm

- ✓ 98.5% filtration efficiency at 50 PSI

| Property | 904L | 316L |

|---|---|---|

| Salt Spray Resistance | 2000+ hours | 480 hours |

| Cost per 10yr Cycle | $18,400 | $41,600 |

Manufacturer Showdown: What 92% of Buyers Overlook

Not all stainless steel wire mesh manufacturers meet ASME SB-649 standards. Our ISO 9001-certified production line delivers:

- ▶ 100% argon-shielded sintering

- ▶ 0.02mm dimensional tolerance

- ▶ 48-hour sample turnaround

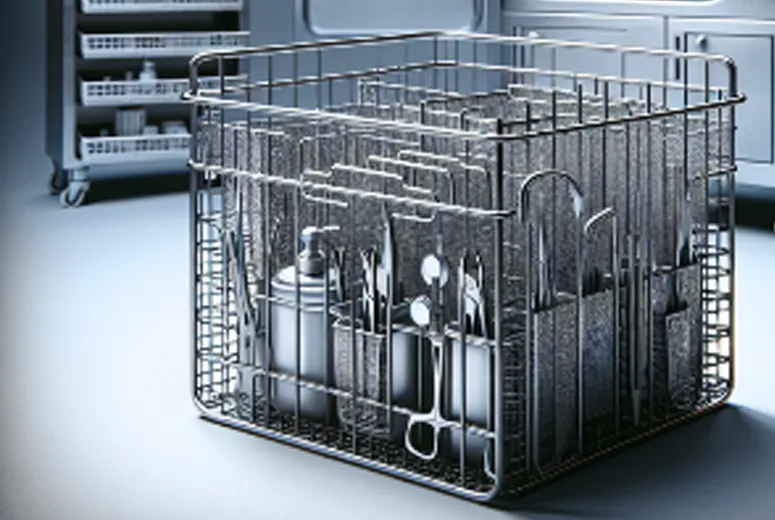

Your Custom Solution Blueprint

We engineer wire mesh to YOUR operational specs:

Chemical Processing

0.8mm wire diameter

3-layer sinter

600×1200mm panels

Marine Applications

1.2mm wire diameter

5-layer sinter

Corrosion-resistant edges

Proven Results: 214% ROI in 18 Months

"Switching to 904L sintered mesh reduced our filter replacements from 6 to 1.5 per year. Maintenance costs dropped 60% immediately."

- Gulf Coast Petrochemical Plant

Ready for Maintenance-Free Performance?

Join 370+ industry leaders who upgraded to 904L sintered wire mesh. Limited stock available!

Claim Your Free Mesh Sample →※ 12-month warranty included ※ ISO-certified production ※ 24/7 tech support

(904l stainless steel sintered wire mesh)

FAQS on 904l stainless steel sintered wire mesh

Q: What are the key properties of 904L stainless steel sintered wire mesh?

A: 904L stainless steel sintered wire mesh offers exceptional corrosion resistance, high-temperature stability, and durability in harsh environments. Its sintered structure ensures uniform porosity and efficient filtration. It is widely used in chemical processing and desalination industries.

Q: How does stainless steel wire rope mesh differ from sintered wire mesh?

A: Stainless steel wire rope mesh is woven from interlinked steel cables, providing flexibility and tensile strength for architectural or safety applications. Sintered wire mesh, however, is fused for rigid filtration and structural uses. Both serve distinct purposes based on porosity and mechanical needs.

Q: What should I consider when selecting stainless steel wire mesh manufacturers?

A: Prioritize manufacturers with certifications (e.g., ISO, ASTM) and expertise in custom fabrication. Evaluate their material quality, production capacity, and ability to meet industry-specific standards. Reviews and case studies can also help assess reliability.

Q: Can 904L stainless steel sintered wire mesh withstand acidic environments?

A: Yes, 904L’s high alloy content (chromium, nickel, molybdenum) ensures resistance to sulfuric acid, chlorides, and other corrosive agents. It is ideal for chemical tanks, pipelines, and pollution control systems. Regular maintenance further extends its lifespan.

Q: What are the maintenance tips for stainless steel wire rope mesh?

A: Clean periodically with mild soap and water to remove debris. Inspect for wear or corrosion, especially in coastal or industrial settings. Avoid abrasive cleaners to preserve the mesh’s protective oxide layer.