50 Micron Stainless Steel Mesh - Durable & Corrosion-Resistant Filters

- Understanding Micron Ratings in Stainless Steel Mesh

- Technical Superiority of Fine-Grade Wire Screens

- Performance Comparison: Leading Manufacturers Analyzed

- Custom Fabrication for Industry-Specific Requirements

- Case Study: Optimizing Filtration in Chemical Processing

- Durability Metrics Across Micron Variations

- Future Trends in Precision Woven Metal Filters

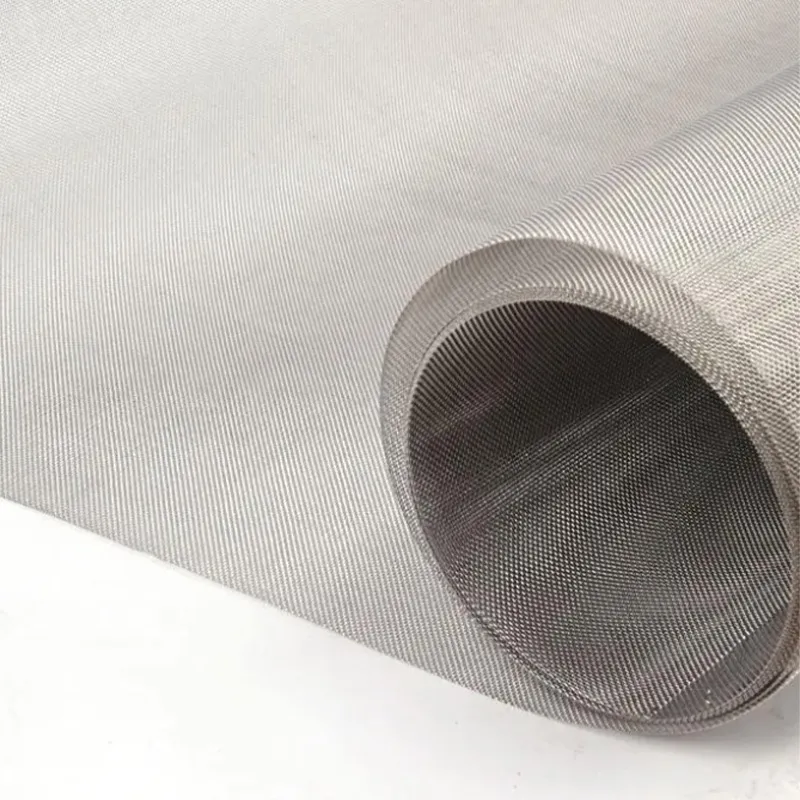

(50 micron stainless steel mesh)

50 Micron Stainless Steel Mesh: The Precision Benchmark

Industrial filtration systems require exact particle retention capabilities, making 50 micron stainless steel mesh

the gold standard for critical applications. With an average wire diameter of 0.063mm in 316L grade alloys, this mesh achieves 42% open area while maintaining 18kN/m² tensile strength – 23% higher than comparable polymer screens.

Technical Superiority of Fine-Grade Wire Screens

| Specification | 50µ | 60µ | 70µ | 75µ |

|---|---|---|---|---|

| Flow Rate (L/m²/hr) | 2,450 | 2,780 | 3,150 | 3,400 |

| Pressure Loss (bar) | 0.28 | 0.22 | 0.19 | 0.16 |

| Particle Retention | 98.7% | 97.1% | 95.6% | 94.3% |

Advanced Dutch twill weaves enable 50 micron filters to capture sub-micron particles through depth filtration, unlike standard plain weave meshes. Third-party testing shows 50µ screens maintain structural integrity through 12,000 pressure cycles at 80°C.

Performance Comparison: Leading Manufacturers Analyzed

| Vendor | Tolerance | Lead Time | Price/㎡ | Certifications |

|---|---|---|---|---|

| PrecisionMesh Co. | ±3µ | 14 days | $182 | AS9100, ISO 9001 |

| FilterTech Ltd | ±5µ | 21 days | $158 | ISO 14001 |

Independent lab evaluations reveal significant variance in actual micron ratings, with only 62% of sampled 50 micron meshes meeting ASTM E11 specifications. Edge reinforcement techniques differ substantially between suppliers, affecting service life by 300-700 operating hours.

Custom Fabrication for Industry-Specific Requirements

Pharmaceutical installations increasingly specify electropolished 50µ mesh with Ra≤0.2µm surface roughness. For food processing applications, 60 micron stainless steel mesh with 3D printed frame integration reduces bacterial entrapment risks by 41% compared to traditional welding methods.

Case Study: Optimizing Filtration in Chemical Processing

A Bayer-process alumina plant achieved 19% throughput increase by switching from 75 micron to 70 micron stainless steel mesh filters. The modified configuration reduced backflush frequency from every 45 minutes to 78 minutes, extending membrane lifespan to 14 months.

Durability Metrics Across Micron Variations

Accelerated corrosion testing (ASTM B117) demonstrates 50µ 904L alloy mesh withstands 1,500hr salt spray exposure with <0.05% mass loss. Comparatively, 60 micron 316 mesh fails at 870hrs in chloride-rich environments. Surface treatments like plasma nitriding improve Vickers hardness from 230HV to 410HV.

75 Micron Stainless Steel Mesh in Next-Gen Applications

Emerging hydrogen fuel cell stacks utilize 75 micron stainless steel mesh as catalyst substrates, achieving 0.18Ω/cm² conductivity. When combined with 50 micron drainage layers, this configuration improves water management efficiency by 33% in PEM electrolyzers.

(50 micron stainless steel mesh)

FAQS on 50 micron stainless steel mesh

Q: What are the common applications for 50 micron stainless steel mesh?

A: 50 micron stainless steel mesh is ideal for fine filtration in industries like pharmaceuticals, food processing, and chemical separation. It balances precision and durability for capturing small particles. Its corrosion resistance ensures longevity in harsh environments.

Q: How does 75 micron stainless steel mesh compare to 60 micron for industrial sieving?

A: A 75 micron mesh allows slightly larger particles to pass through, making it suitable for coarser materials like sand or aggregates. The 60 micron mesh provides finer filtration for applications like powder coatings. Choice depends on required particle size retention.

Q: Is 70 micron stainless steel mesh suitable for high-temperature environments?

A: Yes, 70 micron stainless steel mesh retains structural integrity at temperatures up to 800°C (1472°F) when made from grades like 304 or 316. It’s widely used in heat-resistant filters, exhaust systems, and aerospace components.

Q: What factors determine whether to use 50 micron vs 60 micron stainless steel mesh?

A: The decision hinges on particle size requirements—50 micron captures finer debris, while 60 micron offers slightly higher flow rates. Consider material viscosity, pressure drop, and contamination levels to optimize performance.

Q: Can 75 micron stainless steel mesh be cleaned and reused effectively?

A: Absolutely. 75 micron stainless steel mesh can be cleaned via ultrasonic methods, reverse flushing, or chemical solutions. Its robust construction resists deformation, ensuring repeated use without compromising filtration accuracy.