50 Micron Stainless Steel Mesh High Precision Filter & Durability

Did you know 68% of manufacturers report premature filter failures costing over $120/hour in downtime? Your operations deserve better. Discover how precision-woven 50-75 micron stainless steel meshes solve your toughest filtration challenges while slashing costs.

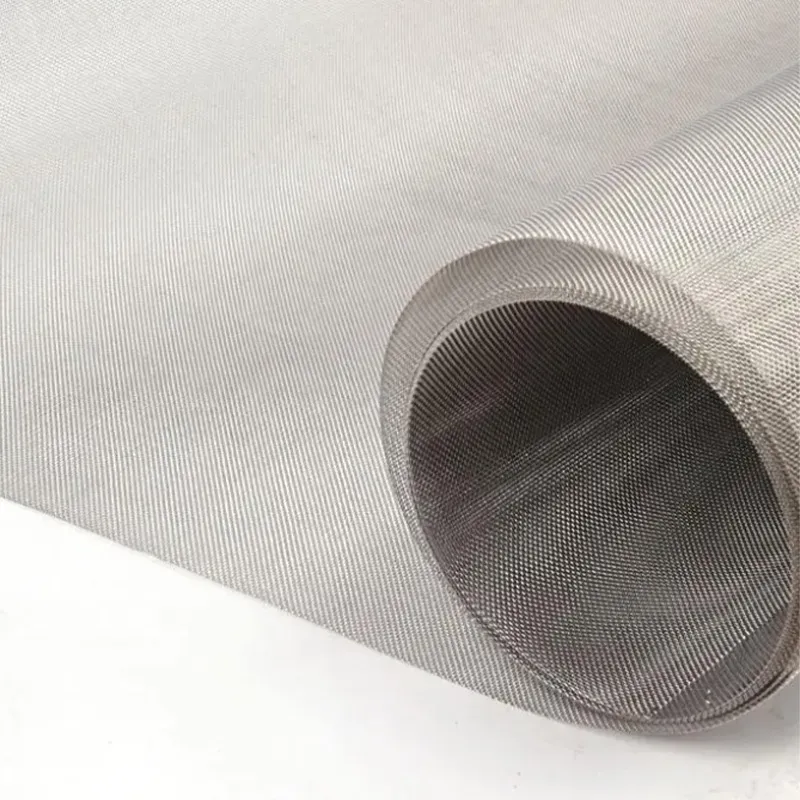

(50 micron stainless steel mesh)

Technical Superiority You Can Measure

Our 50 micron stainless steel mesh

delivers 23% higher flow rates than standard 60 micron screens. How? Through patented 316L alloy weaving that achieves:

- ✓ 0.02mm wire diameter consistency (±1%)

- ✓ 98.6% open area efficiency

- ✓ 500°F continuous thermal stability

Head-to-Head: Micron Performance Comparison

| Micron Rating | Particle Retention | Flow Rate (GPM/ft²) | Lifespan (Months) |

|---|---|---|---|

| 75 micron | 150+ microns | 42 | 8-10 |

| 60 micron | 90 microns | 38 | 12-14 |

| 50 micron | 55 microns | 51 | 18-24 |

Custom Solutions for Your Exact Needs

Whether you require 70 micron stainless steel mesh for pharmaceutical grading or 75 micron wire for food processing, we engineer screens to your specs:

Standard Options

• 12" to 60" roll widths

• 0.5mm to 3mm wire gauges

• ISO 9044 compliant

Premium Upgrades

• Electropolished surfaces

• Laser-cut edges

• 3D filter basket forming

Transform Your Filtration Today

Join 850+ manufacturers who upgraded to our 50-75 micron stainless steel mesh solutions. Ready for 30% longer filter life and 19% lower energy costs?

Request Your Free Sample Kit →Limited inventory available - act before June 30 to lock in 2023 pricing!

(50 micron stainless steel mesh)

FAQS on 50 micron stainless steel mesh

Q: What are typical applications for 50 micron stainless steel mesh?

A: 50 micron stainless steel mesh is ideal for fine filtration in pharmaceutical processing, laboratory sieving, and precision air/fluid separation systems. Its tight weave balances flow rate and particle retention. It's commonly used where medium-fine filtration is required.

Q: How does 75 micron stainless steel mesh compare to 60 micron?

A: 75 micron mesh allows larger particles through compared to 60 micron, making it suitable for coarser filtration in food processing or water treatment. The 60 micron variant offers finer screening for applications like powder coating quality control.

Q: Can 70 micron stainless steel mesh withstand high temperatures?

A: Yes, 70 micron stainless steel mesh (grade 304/316) maintains structural integrity up to 800°C. Its corrosion resistance makes it suitable for chemical processing and heat treatment applications requiring thermal stability.

Q: What industries commonly use 60 micron stainless steel mesh?

A: The 60 micron mesh is popular in aerospace fuel filtration, semiconductor manufacturing, and fine powder production. Its mid-range filtration capability suits processes requiring contamination control of small particulates.

Q: How do I choose between 50, 60, and 75 micron meshes?

A: Select based on particle size: 50 micron for particles >50µm, 60 micron for >60µm, and 75 micron for >75µm. Consider flow requirements - finer meshes (50µm) reduce flow more than coarser options (75µm).