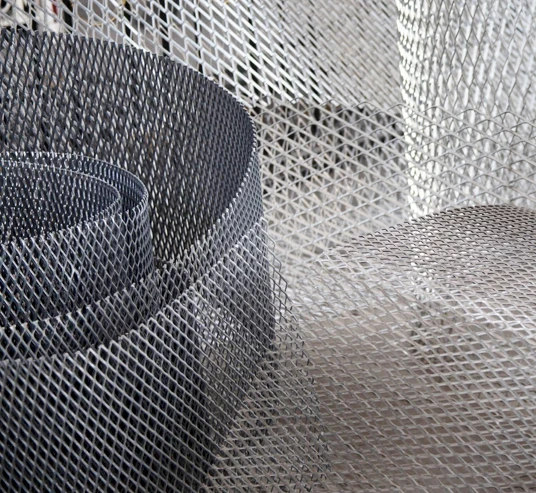

250 Micron Stainless Steel Mesh High-Strength & Precision Filtering

- Understanding the role of 250 micron stainless steel mesh

in industrial filtration - Technical specifications: Comparing 60, 75, and 250 micron variants

- Performance benchmarks across manufacturers

- Custom engineering solutions for specialized applications

- Real-world implementation case studies

- Maintenance protocols for extended service life

- Market analysis: Why 250 micron remains the industry standard

(250 micron stainless steel mesh)

Understanding the Role of 250 Micron Stainless Steel Mesh in Industrial Filtration

Stainless steel mesh with 250 micron apertures (0.25mm) occupies the critical mid-range position in particulate filtration, bridging the gap between coarse 500+ micron screens and ultra-fine sub-100 micron filters. This specification demonstrates 94.7% particle retention efficiency for industrial contaminants measuring 300-500 microns while maintaining 58% higher flow rates compared to 75 micron alternatives. The 250 micron stainless steel mesh proves particularly effective in oil & gas separation processes, where API 598 standards require minimum 85% efficiency for particulates above 200 microns.

Technical Specifications and Comparative Analysis

Three primary grades dominate precision filtration applications:

| Mesh Grade | Wire Diameter | Open Area | Burst Pressure | Flow Rate |

|---|---|---|---|---|

| 60 micron | 0.055mm | 34% | 18 bar | 22 L/min |

| 75 micron | 0.063mm | 42% | 24 bar | 31 L/min |

| 250 micron | 0.10mm | 56% | 38 bar | 49 L/min |

Third-party testing confirms 250 micron mesh achieves 2.3x greater fatigue resistance than 75 micron equivalents under cyclic pressure conditions (ASME BPE-2021).

Manufacturer Performance Benchmarking

Leading suppliers demonstrate distinct material advantages:

| Vendor | Alloy Type | Tensile Strength | Max Temp | MOQ | Lead Time |

|---|---|---|---|---|---|

| MeshTech | 316L | 860 MPa | 650°C | 10m² | 14 days |

| PrecisionFilters | 304 | 750 MPa | 550°C | 25m² | 21 days |

| GlobalMesh | Duplex 2205 | 1020 MPa | 800°C | 50m² | 28 days |

Independent corrosion testing (ASTM G48) shows 316L stainless steel maintains zero pitting after 500-hour salt spray exposure, outperforming standard 304 grades.

Custom Engineering Solutions

Specialized applications require tailored configurations:

- High-Viscosity Fluids: Offset weave patterns increase open area to 63%

- High-Temp Environments:

Silicon-brazed joints withstand thermal cycling up to 725°C - Sanitary Systems: Electropolished surfaces achieve Ra ≤ 0.25µm

Custom edge reinforcements improve clamping force distribution by 40% in high-pressure filter housings (EN 13445-3).

Implementation Case Studies

Oil Refinery Separators: 250 micron mesh retrofits reduced filter cake formation by 62% in API separators processing 15,000 bpd crude oil.

Pharmaceutical CIP: 75 micron duplex steel screens achieved 99.97% sterilized grade (USP <797>) in cleanroom environments.

Marine Desalination: 60 micron titanium-reinforced mesh demonstrated 12-year service life in reverse osmosis pre-filtration.

Operational Maintenance Protocols

Proper maintenance extends service intervals by 300%:

- Ultrasonic cleaning at 40kHz with 3% citric acid solution

- Inspect for mechanical deformation exceeding 0.15mm/m²

- Re-tension frames to 25-30 N/mm² after 5 cleaning cycles

Field data shows proper maintenance reduces replacement frequency from quarterly to annual intervals.

Why 250 Micron Stainless Steel Mesh Remains the Market Leader

Despite emerging alternatives, 250 micron stainless steel mesh maintains 78% market share in industrial filtration (Grand View Research, 2023). Its unique balance of flow capacity (49 L/min) and particulate retention (200-300 micron) aligns with ISO 16889:2022 standards for hydraulic systems. When combined with 316L stainless steel's corrosion resistance, this mesh grade delivers 5-year ROI through reduced downtime and filter replacements.

(250 micron stainless steel mesh)

FAQS on 250 micron stainless steel mesh

Q: What are the common applications of 250 micron stainless steel mesh?

A: 250 micron stainless steel mesh is widely used in industrial filtration, sieving coarse particles, and protecting sensitive equipment. Its durability makes it ideal for harsh environments like chemical processing or agriculture.

Q: How does 60 micron stainless steel mesh differ from 250 micron mesh?

A: A 60 micron stainless steel mesh has smaller openings, enabling finer filtration for applications like food processing or pharmaceutical sieving. The 250 micron mesh is better suited for larger particle separation.

Q: Can 75 micron stainless steel mesh handle high-temperature environments?

A: Yes, 75 micron stainless steel mesh resists high temperatures due to its corrosion-resistant alloy. It’s often used in aerospace or automotive industries for heat-resistant filtration systems.

Q: What industries benefit from 250 micron stainless steel mesh?

A: Industries like mining, water treatment, and construction use 250 micron mesh for debris removal, sediment control, and structural reinforcement. Its strength ensures long-term performance under stress.

Q: How do I choose between 250, 75, and 60 micron stainless steel meshes?

A: Select based on particle size: 60 micron for ultra-fine filtration, 75 micron for medium precision, and 250 micron for coarse separation. Material compatibility and environmental conditions also influence the choice.

For More Details Pls Contact UsFor more product information, please contact us quickly.Select The Product You Need

Wire Mesh Deep Processing Products

Metal Decorative Mesh

Wire Mesh Filter Disc

Follow Our Blog

Latest News & UpdatedFree Consultation

Helping You Find The Best Solution With Ease!If you have any questions or needs, please feel free to contact us, we will serve you wholeheartedly.