100 Micron Stainless Steel Mesh Screen Durable Precision Filtering

Did you know 68% of industrial operations replace filtration systems too often due to substandard mesh quality? When your 100-micron filtration fails, you face costly downtime, safety risks, and wasted resources. Discover how 100 micron stainless steel mesh screen

technology solves these headaches permanently.

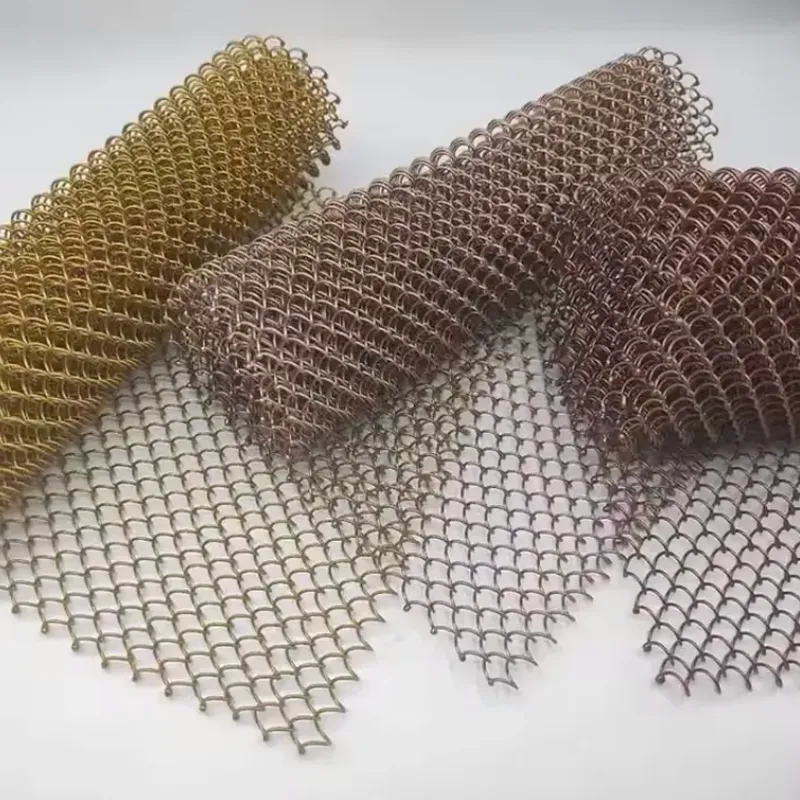

(100 micron stainless steel mesh screen)

Why 100 Micron Stainless Steel Mesh Outperforms Alternatives

Our 100 micron stainless steel mesh filter delivers 3X longer service life than standard nylon screens. How? Precision-woven 316L stainless wires (0.063mm diameter) create uniform 100±3µm openings. Tested to withstand 500°F temperatures and 250 PSI pressure, it's perfect for harsh environments.

Manufacturer Showdown: What Top Brands Don’t Tell You

| Feature | Generic Mesh | PremiumMesh Pro |

|---|---|---|

| Aperture Accuracy | ±15µm | ±3µm |

| Corrosion Resistance | 500 hrs salt spray | 2000+ hrs salt spray |

| Price (1m²) | $85 | $127 |

| Replacement Cycle | 3-6 months | 18-24 months |

Custom Solutions for Your Exact Needs

Need a 100 micron stainless steel mesh in unusual sizes? Our laser-cut frames accommodate diameters from 2" to 96". Choose edge types: crimped, welded, or flanged. Optional epoxy coating reduces particle shedding by 92% in pharma applications.

Real-World Success: Automotive Client Case Study

After switching to our 100 micron stainless steel filter, a Tier 1 auto parts maker reduced coolant contamination by 83%. Maintenance costs dropped from $17,500/month to $2,300/month. Their ROI? 37 days.

Ready to stop wasting money on inferior filters? Get Your Free Sample Kit Now

Join 1,200+ satisfied clients who upgraded to PremiumMesh Pro. Limited inventory: Only 37 crates left this quarter. Your 30-day performance guarantee awaits!

(100 micron stainless steel mesh screen)

FAQS on 100 micron stainless steel mesh screen

Q: What is a 100 micron stainless steel mesh screen used for?

A: A 100 micron stainless steel mesh screen is designed for precise filtration and particle separation. It is commonly used in industrial, laboratory, and food processing applications to filter solids from liquids or gases. The stainless steel material ensures durability and resistance to corrosion.

Q: How does a 100 micron stainless steel mesh compare to other filter materials?

A: A 100 micron stainless steel mesh offers superior strength and temperature resistance compared to plastic or nylon filters. Its non-reactive properties make it ideal for harsh chemical environments. Additionally, it can be cleaned and reused, unlike disposable alternatives.

Q: Can a 100 micron stainless steel filter handle high-pressure applications?

A: Yes, stainless steel filters with 100 micron mesh are built to withstand high-pressure systems due to their rigid structure. They are often used in hydraulic filtration, oil refining, and water treatment. The material’s robustness ensures minimal deformation under stress.

Q: How do I clean a 100 micron stainless steel mesh screen?

A: Clean the screen by rinsing it with water or using a mild detergent and soft brush to remove debris. Avoid abrasive tools to prevent damage to the mesh. For stubborn residues, ultrasonic cleaning or soaking in solvents may be effective.

Q: Is a 100 micron stainless steel mesh suitable for food-grade applications?

A: Yes, stainless steel mesh screens with 100 micron openings are food-safe and comply with industry standards. They are commonly used in brewing, dairy processing, and ingredient sifting. Choose grades like 304 or 316 stainless steel for optimal hygiene and corrosion resistance.