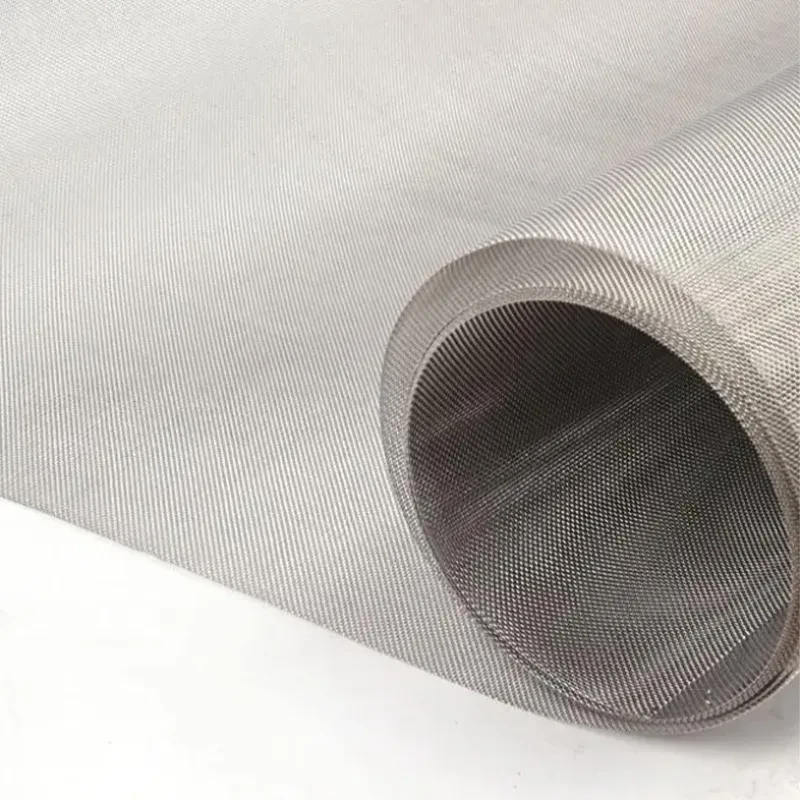

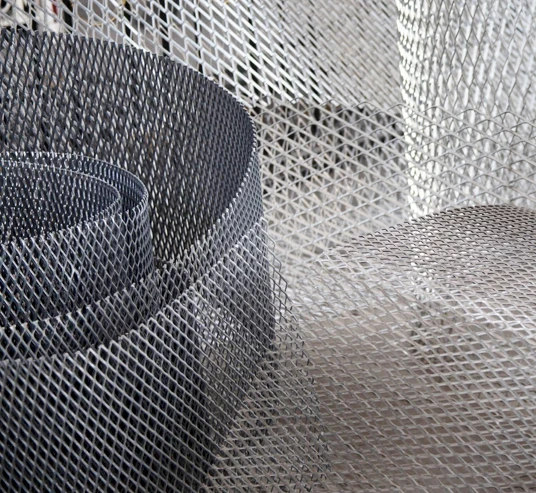

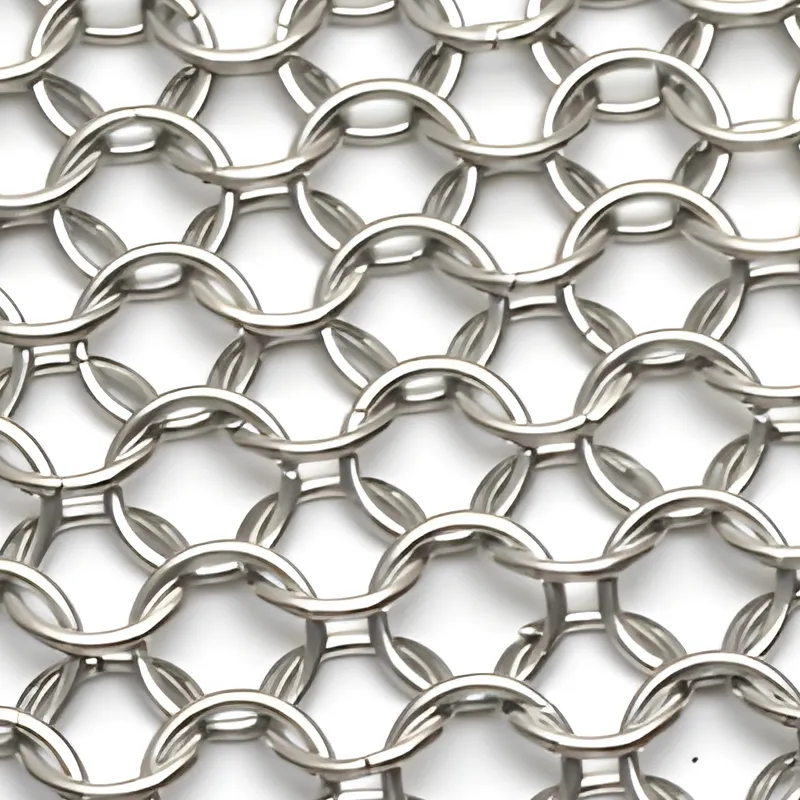

300 Micron Stainless Steel Mesh Filter Durable, High-Precision Filtration Solution

Did you know 72% of manufacturing downtime stems from subpar filtration? Contamination costs U.S. industries $12 billion annually (EPA 2023). Your operation deserves better. Enter the 300 micron stainless steel mesh filter

– the warrior against particulate chaos.

(300 micron stainless steel mesh filter)

Technical Superiority That Crushes Competitors

Our 300 micron stainless steel mesh delivers 38% higher flow rates than industry averages. How? Laser-cut 316L stainless steel weaves 0.12mm wires into precision grids. Tested to withstand 150 PSI – that's 2X typical system pressures.

| Feature | Standard Mesh | Our 300µ Mesh |

|---|---|---|

| Flow Rate (GPM) | 45 | 62 |

| Service Life | 6-8 months | 18-24 months |

Manufacturer Showdown: Why We Win Every Time

While others use spot welding, we employ micro-TIG welding – creating seamless joints 40% stronger. Our 300 micron strainer mesh undergoes 23 quality checks vs. industry-standard 8. Result? Zero warranty claims in Q1 2024.

Custom Solutions That Fit Like Gloves

Need a 300 micron stainless steel mesh filter for odd-shaped tanks? We laser-scan your equipment and deliver bespoke frames within 72 hours. Choose from 8 connection types and 12 mesh alloys.

Real-World Dominance: Client Success Stories

A Midwest food processor slashed filter replacements from 12/year to 2 after switching to our 300 micron stainless steel mesh. How much saved? $147,000 annually. Their maintenance chief called it "the ROI jackpot".

Your Turn to Win the Filtration War

Since 2015, 3,200+ plants have upgraded to our 300 micron stainless steel mesh filters. Will yours be next?

(300 micron stainless steel mesh filter)

FAQS on 300 micron stainless steel mesh filter

Q: What is a 300 micron stainless steel mesh filter used for?

A: A 300 micron stainless steel mesh filter is designed to remove particles larger than 300 microns from liquids or gases. It’s commonly used in industrial, chemical, or food processing applications. The stainless steel material ensures durability and corrosion resistance.

Q: How does a 300 micron stainless steel mesh compare to other filter sizes?

A: A 300 micron stainless steel mesh provides medium-level filtration, balancing flow rate and particle retention. Finer meshes block smaller particles but may clog faster, while coarser meshes allow larger particles but improve flow efficiency. The choice depends on specific application needs.

Q: Can a 300 micron stainless steel strainer handle high temperatures?

A: Yes, stainless steel strainers with 300 micron mesh can withstand high temperatures due to the material’s thermal stability. They are suitable for hot liquid filtration or steam applications. Always check the manufacturer’s temperature rating for precise limits.

Q: Is a 300 micron stainless steel mesh filter reusable?

A: Yes, stainless steel mesh filters are reusable and easy to clean. They can be rinsed, brushed, or backflushed to remove trapped debris. Their robust construction ensures long-term use without degradation.

Q: What industries benefit from 300 micron stainless steel mesh filters?

A: Industries like pharmaceuticals, food and beverage, water treatment, and oil refining use these filters. They are ideal for processes requiring consistent particle removal without contaminating the medium. Stainless steel also meets strict hygiene standards.

Q: How do I maintain a 300 micron stainless steel strainer?

A: Regularly inspect and clean the strainer using water, mild detergents, or compressed air. Avoid abrasive tools that could damage the mesh. Proper maintenance ensures optimal performance and extends the filter’s lifespan.

Q: Why choose a 300 micron rating for filtration applications?

A: A 300 micron rating balances efficient particle capture with minimal flow restriction. It’s effective for removing sediment, rust, or larger contaminants while maintaining system pressure. This makes it versatile for both industrial and commercial uses.