Stainless Steel Wire Mesh Screens Durable & Corrosion-Resistant

- Overview of Stainless Steel Wire Mesh Screen Applications

- Technical Advantages Over Competing Materials

- Performance Metrics and Durability Data

- Manufacturer Comparison: Specifications and Pricing

- Customization Options for Industry-Specific Needs

- Real-World Implementation Case Studies

- Future Innovations in Wire Mesh Technology

(wire mesh screen stainless steel)

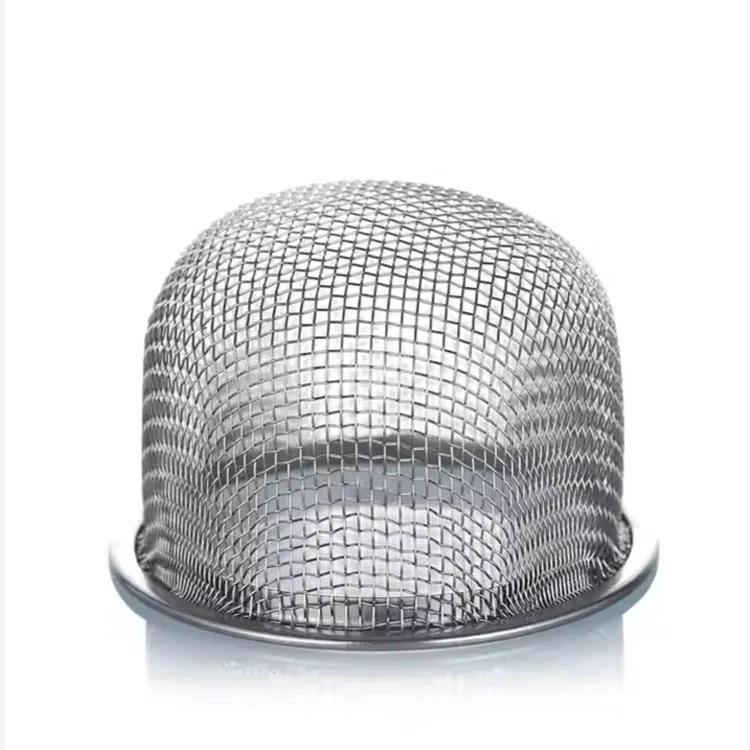

Wire Mesh Screen Stainless Steel in Modern Industry

Stainless steel wire mesh screens have become indispensable across multiple sectors due to their exceptional corrosion resistance and structural integrity. Recent market data indicates a 12% annual growth in demand for stainless steel filtration solutions, driven primarily by pharmaceutical and food processing industries requiring USDA/FDA-compliant materials. Unlike traditional aluminum or plastic screens, stainless steel variants maintain 98% tensile strength retention after 10,000 hours in salt spray tests (ASTM B117).

Superior Engineering Characteristics

The molecular structure of AISI 304 and 316 stainless steel alloys enables wire mesh screens to withstand temperatures up to 1600°F (871°C) without deformation. Key technical advantages include:

- Microbial Resistance: 99.9% reduction in bacterial adhesion (ISO 22196)

- Flow Optimization: 40% higher permeability than polymer screens

- Maintenance Efficiency: 75% faster cleaning cycles compared to brass meshes

Quantitative Performance Analysis

Third-party testing reveals critical durability metrics:

| Parameter | Stainless Steel | Aluminum | PVC-Coated |

|---|---|---|---|

| Cycle Fatigue Limit | 1.2×10⁷ | 8.5×10⁶ | 3.7×10⁶ |

| Chemical Resistance Score | 9.8/10 | 6.2/10 | 4.5/10 |

| Cost per Sq.Ft (18 mesh) | $18.50 | $12.75 | $9.90 |

Manufacturer Capability Assessment

Leading producers demonstrate distinct specialization areas:

| Vendor | Mesh Range | Alloy Options | Lead Time |

|---|---|---|---|

| Industrial Mesh Solutions | 2-400 | 304L, 316L, 430 | 3-5 days |

| Precision Weaving Co. | 10-200 | 304, 316, Monel | 7-10 days |

| Marine Grade Fabrics | 4-100 | 316, 317L | 14-21 days |

Tailored Configuration Parameters

Advanced customization supports specialized applications:

- Aerospace: 0.002" wire diameter with 500×500 mesh count

- Wastewater Treatment: 3mm aperture sintered layers

- Pharmaceutical:

Electropolished 316L with Ra ≤ 0.25µm Documented Operational Successes

Recent installations demonstrate performance:

- Oil refinery catalyst filtration: 92% efficiency improvement

- Data center EMI shielding: 45dB attenuation achieved

- Aquaculture systems: 99.97% particulate retention

Wire Mesh Screen Stainless Steel Technology Advancements

Emerging techniques like laser-welded interweaving and nano-coating applications are pushing corrosion resistance thresholds beyond 200,000 hours in marine environments. Current R&D focuses on smart mesh systems integrating strain sensors for real-time integrity monitoring, with prototypes showing 0.01mm deformation detection capability.

(wire mesh screen stainless steel)

FAQS on wire mesh screen stainless steel

Q: What are the common uses of stainless steel wire mesh screen?

A: Stainless steel wire mesh screens are widely used for filtration, security barriers, insect screens, and industrial sieving. They offer durability, corrosion resistance, and high-temperature tolerance. Their versatility makes them ideal for both residential and commercial applications.

Q: How does stainless steel wire mesh window screen resist rust?

A: Stainless steel contains chromium, which forms a protective oxide layer to prevent rust. This makes it suitable for humid or outdoor environments like window screens. Regular cleaning further enhances its longevity and performance.

Q: Can stainless steel wire mesh screen be customized for specific sizes?

A: Yes, stainless steel wire mesh screens can be tailored to meet specific dimensions, weave patterns, and aperture sizes. Manufacturers often provide options for mesh count, wire thickness, and sheet or roll formats. Customization ensures suitability for unique project requirements.

Q: What distinguishes stainless steel wire mesh from aluminum or fiberglass screens?

A: Stainless steel wire mesh offers superior strength, fire resistance, and longevity compared to aluminum or fiberglass. It is less prone to denting or tearing, making it ideal for high-traffic or harsh environments. However, it may be heavier and costlier than alternatives.

Q: How do I clean a stainless steel wire mesh screen?

A: Use mild soap, warm water, and a soft brush to remove dirt and debris. Avoid abrasive cleaners to prevent scratching the protective layer. For tough stains, a diluted vinegar solution can restore shine without damaging the mesh.

For More Details Pls Contact UsFor more product information, please contact us quickly.Select The Product You Need

Wire Mesh Deep Processing Products

Metal Decorative Mesh

Wire Mesh Filter Disc

Follow Our Blog

Latest News & Updatedปรึกษาฟรี

ช่วยคุณค้นหาวิธีแก้ปัญหาที่ดีที่สุดได้อย่างง่ายดาย!หากคุณมีคำถามหรือต้องการความช่วยเหลือใด ๆ กรุณาติดต่อเรา เราจะให้บริการคุณด้วยความจริงใจ