High-Quality Wire Mesh Filters | Durable & Efficient | GPT-4 Turbo

In recent years, the wire mesh filter industry has experienced remarkable evolution, spurred by technological advancements, increasing industrial filtration requirements, and the rising call for sustainable solutions. In this report, we explore wire mesh filter and related solutions such as steel expanded metal, decorative metal grilles for cabinet doors, and stainless steel expanded sheet. We will examine technical parameters, fabrication processes, market trends, manufacturer comparison, customization plans, and real-world application cases, making this the definitive resource for engineers, designers, and procurement professionals.

Industry Overview & Trends (2024)

The global wire mesh filter market was valued at USD 2.21 billion in 2023, projected to reach USD 2.93 billion by 2028, growing at CAGR of 5.8%. Robust demand from oil & gas, chemical, food processing, metallurgy, and water treatment sectors continues to drive advancement in both product quality and manufacturing automation.

Key drivers:

- Stringent emission & filtration standards (ISO 16889, ANSI B93.30.1, FDA-compliance)

- Expansion of smart manufacturing and predictive maintenance (with real-time monitoring sensors integrated into filtration assemblies)

- Increasing focus on energy efficiency, corrosion resistance, extended service life, and operational cost reduction

Steel expanded metal and stainless steel expanded sheet are in demand for their superior strength-to-weight ratio, decorative potential, and durability. Decorative metal grilles for cabinet doors are increasingly specified for modern kitchens and industrial enclosures, valued for their visual appeal and ventilation function.

Technical Parameters: Core Specification Table

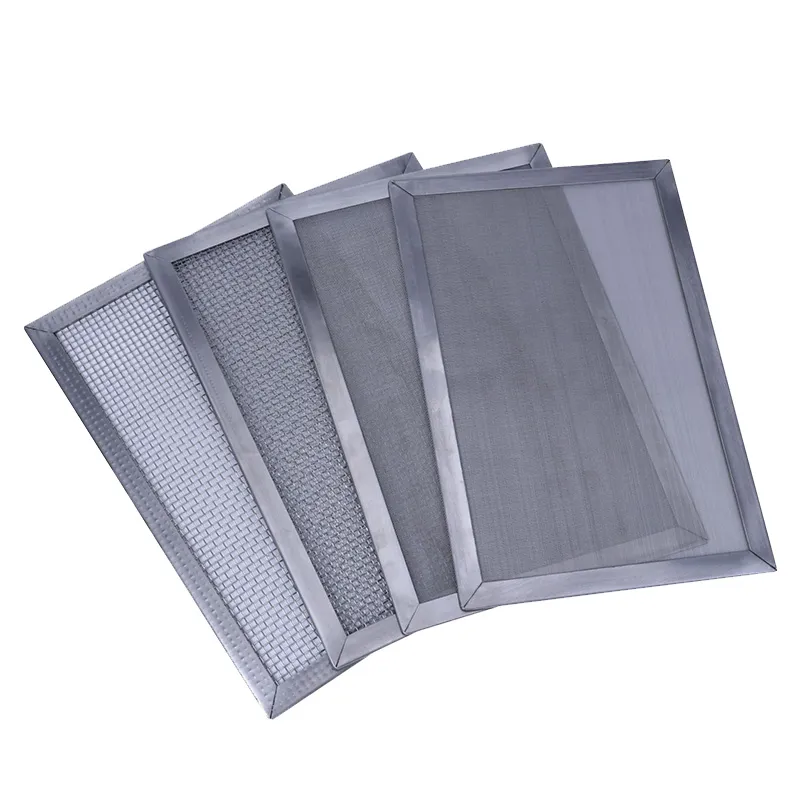

Below is a detailed comparison table for wire mesh filter products, including mesh discs, steel expanded sheets, and decorative metal grilles. For in-depth product information for wire mesh filter disc, please refer to the official site.

| Product | Material | Mesh Count (per inch) | Thickness | Filtration Accuracy (μm) | Corrosion Resistance | Max Operating Temp (°C) | Certifications | Typical Application |

|---|---|---|---|---|---|---|---|---|

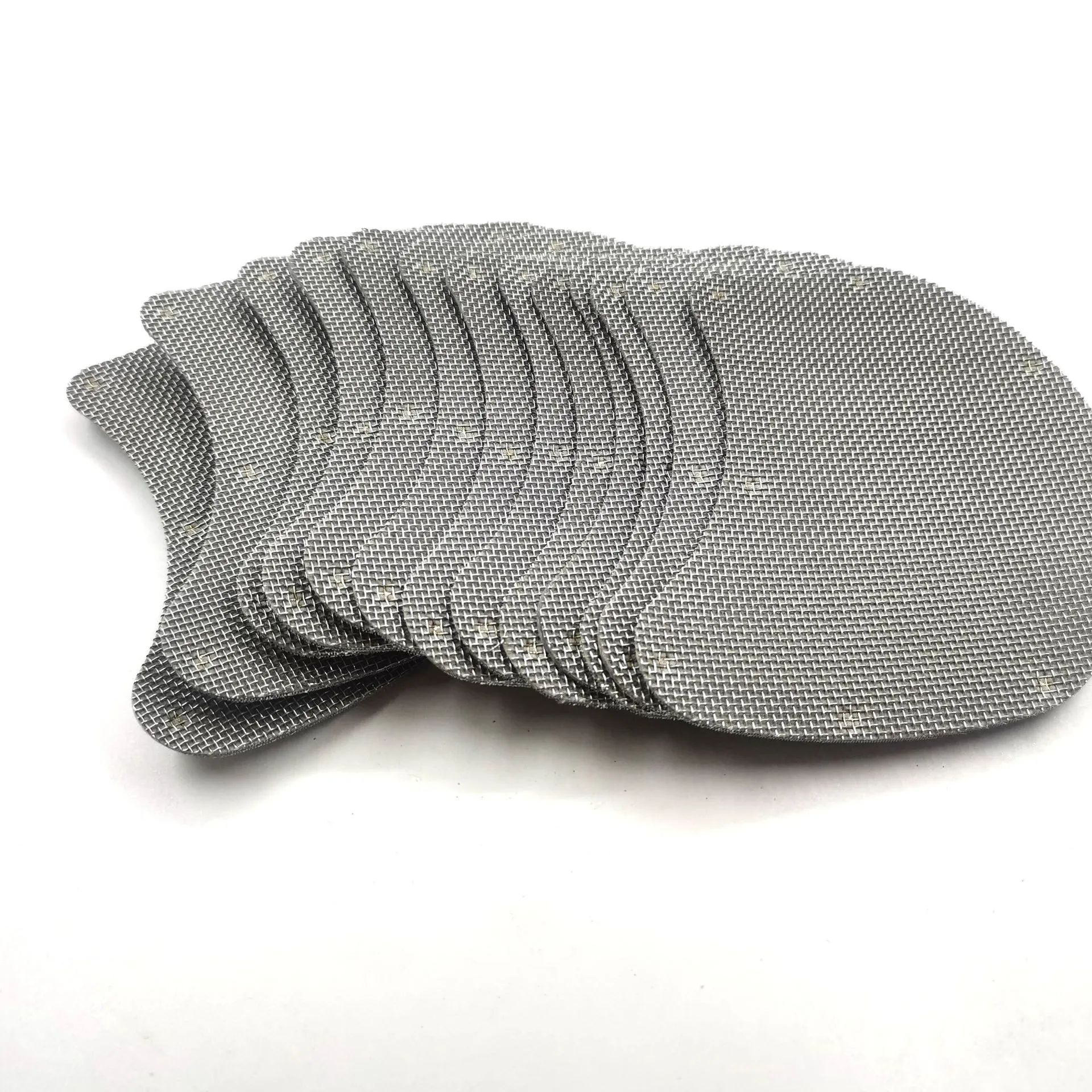

| Wire Mesh Filter Disc | 304/316L Stainless Steel | 10–325 | 0.05–2mm | 5–350 | Excellent | 600 | ISO 9001, FDA, RoHS | Petr. & Chem., Water, Food |

| Steel Expanded Metal | Carbon Steel, 304SS | – | 0.3–6mm | 500–5000 | Good/Excellent | 400 | CE, ISO 14001 | Construction, Auto, Fencing |

| Decorative Metal Grilles | Alum., Brass, Stainless Steel | – | 0.7–3mm | Varies | Very Good | 150 | EN13501-1, ISO 9001 | Cabinets, Ventilation |

| Stainless Steel Expanded Sheet | 316/304 SS | – | 0.5–6mm | 1000–5000 | Excellent | 900 | SGS, ISO 9001 | Refineries, Power, Marine |

Manufacturing Process: Wire Mesh Filter Disc

The manufacturing of wire mesh filter discs involves a series of precision steps to ensure high performance and strict adherence to international standards such as ISO 16889 and FDA regulations.

304/316L SS, Custom Alloys

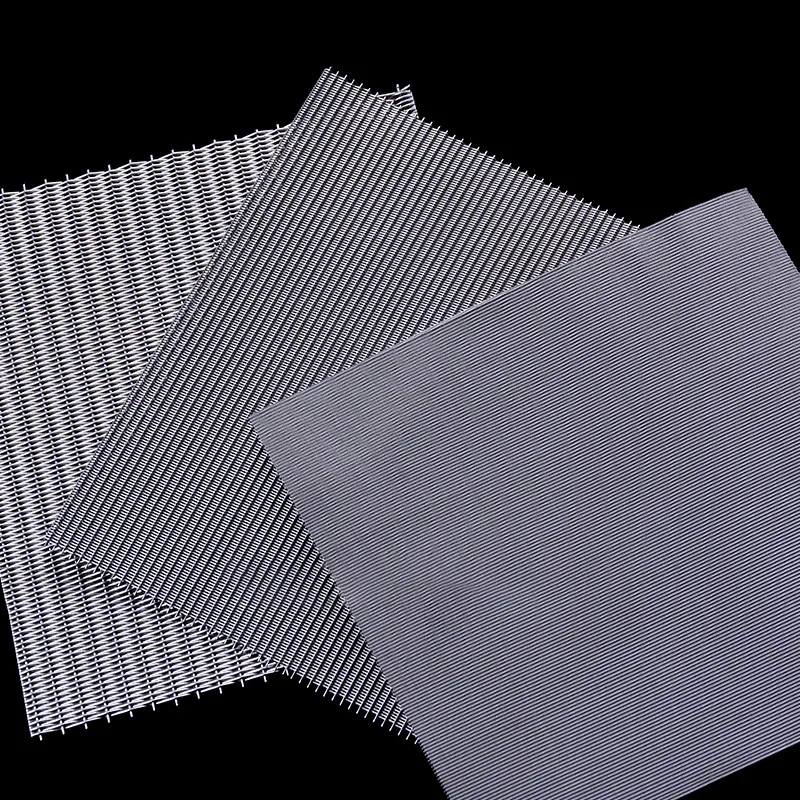

Dutch/Plain Twill, Expanded Metal

CNC, Laser, Precision Blanking

TIG/CO2 Welding, Framed/Frameless

Pickling, Passivation, Electro-polishing

Pore Size, Burb Free, Pressure Test

- Key Points: Edge welding provides dimensional stability; pickling and passivation remove contaminants and enhance corrosion resistance; QA includes inspection for calibration and integrity testing (bubble point, burst pressure) as per ISO/ANSI/FDA standards.

- Technologies: CNC blanking ensures ±0.01mm accuracy; laser cutting avoids wire burring; fully automated filtration porometer checks guarantee 100% inspection on mesh count and aperture size.

Wire Mesh Filter Disc: Key Technical Indicators (2024)

Performance Comparison: Mesh Types (Filtration, Lifespan, Cost)

| Mesh Type | Filtration Accuracy (μm) | Corrosion Resistance | Lifespan (Expected, Months) | Cost (Relative) |

|---|---|---|---|---|

| Dutch Weave SS | 5–80 | ★★★★★ | ≧36 | High |

| Plain Weave SS | 15–180 | ★★★★★ | ≧30 | Medium |

| Steel Expanded Metal | 500–5000 | ★★★☆☆ | ≧24 | Low |

| Aluminum Grille | 1000–7000 | ★★★☆☆ | 12–18 | Medium–Low |

Application Scenarios: Where Wire Mesh Filter Excel

Wire mesh filters, including discs, screens, and cartridges, are pivotal in industries where precision separation, contamination control, and operational reliability are crucial.

- Petrochemical Processing: Removal of catalyst fines, sand & debris; designed for high temperature and pressure reactors.

- Food & Beverage Manufacturing: Ensures particulates (e.g., fruit pulps, yeast) are filtered out in compliance with FDA/Euro EN 1935 standards.

Stainless steel expanded sheet variants support high-flow, sanitary filtration in breweries. - Water/Wastewater Treatment: Effective at both coarse and fine filtration stages, exceeding ISO 14021 effluent requirements.

- Pharmaceutical & Biotech: Sterile process filtration, customized by mesh aperture and surface finish (electro-polished).

- Decorative & Architectural: Custom metal grilles for cabinet doors and building facades offer ventilation, fire resistance, and a modern aesthetic!

Technical Advantages & Industry Compliance

- High Precision: Selective filtration from 5μm–2000μm; woven or expanded apertures hold tolerance within ±5%.

- Corrosion & Thermal Resistance: 316L grade resists acids, alkalis, and up to 900°C; meets ASTM A580, EN10088 standards.

- Longevity: Expected service life over 30–36 months in harsh conditions; verified by independent testing (SGS, Intertek).

- Hygiene & Cleanability: Electro-polished surfaces approved by FDA for direct food contact.

- Custom Shapes: Circular, annular, multi-layer discs with optional edge bands, frames, or handles.

Manufacturer Comparison: Industry Leaders at a Glance

| Manufacturer | Main Product Range | Certifications | Customization | Global Clients | Lead Time | Average Price Level |

|---|---|---|---|---|---|---|

| QH Filter (China) | Wire Mesh Filter Disc, Expanded Metal, Custom Screens | ISO 9001, FDA, SGS | YES (2D/3D CAD/DXF) | Shell, Danone, ExxonMobil | 7–15 days | Competitive |

| W. S. Tyler (USA) | Industrial Mesh, Filter Elements | ISO 9001, ASTM | YES | GE, Pfizer, Nestle | 15–21 days | Medium–High |

| Haver & Boecker (DE) | Ultra-fine Filter, Architectural Mesh | ISO 14001 | YES | Daimler, BASF | 21–30 days | Premium |

| Nile Wire Mesh (IN) | Expanded Metal, Fencing, Welded Mesh | ISO 9001 | LTD | BHEL, Tata Chem. | 18–24 days | Low–Medium |

Customization Options: Your Solution, Your Way

QH Filter delivers bespoke solutions, offering professional customization for material (304, 316L, Monel, Duplex), mesh count (10–400), diameter (8–600mm), and special geometries (multi-layer, double-mesh, punched frames).

- Free sample prototyping within 7 days for qualified business customers

- Professional pre-sale CAD consultation & after-service support

- Custom Branding & Packaging available

- All production adheres to ISO 9001, RoHS, FDA guidelines

To initiate your project, contact QH Filter at wire mesh filter disc page for immediate assistance.

Application Cases: Real-World Demonstrations

Case 1: Acidic Chemical Plant (Netherlands)

After switching to QH 316L wire mesh filter discs, a leading petrochemical plant reported a reduction in shutdowns from 7 to 2 per year, and annual savings of €45,000 in maintenance.

Case 2: Bottled Water Facility (US)

FDA-inspected 304 wire mesh filter discs reduced particulate load and exceeded EPA compliance, supporting a 20% increase in production capacity without system overhaul.

Case 3: Cabinet Manufacturer (UK)

Decorative SS expanded mesh grilles for cabinet doors led to a 38% reduction in customer complaints about ventilation while increasing product value perception.

Case 4: Power Plant (APAC)

Multi-layered wire mesh filter discs extended turbine lube system intervals, helping the client achieve ISO 19889:2018 filtration targets and a 14-month ROI.

Feedback & Service Network

Client surveys across 24 countries rate QH Filter's support (pre-sale, installation, after-sale) at 97.5% satisfaction, with 24/7 response promise and a standard lead time of 7–20 working days for custom work.

FAQ Section – Wire Mesh Filter Disc: Key Technical FAQ

Delivery, Warranty, and Support

- Standard Lead Time: 7–20 working days for mesh discs, depending on quantity and complexity.

- Quality Guarantee: All wire mesh filter discs are backed by a 12-month warranty for material/workmanship, with batch-level traceability and replacement guarantee.

- Customer Support: 24/7 hotline, online CAD review, bilingual documentation, and onsite installation services available in 16+ countries.