Stainless Steel Wire Mesh Filters High-Efficiency Corrosion-Resistant Wire Mesh Filter Discs

Did you know inefficient filtration costs manufacturers $2.3B annually in downtime? While you're battling clogged filters and corrosion issues, your competitors are switching to stainless steel wire mesh filter

solutions that boost production efficiency by 40%. Let's explore why this industrial game-changer deserves your immediate attention.

(stainless steel wire mesh filter)

Technical Superiority That Outperforms Alternatives

Our wire mesh filter discs deliver 98.7% filtration accuracy across particle sizes from 2μm to 10mm. Unlike polymer screens that degrade in 6-12 months, our 316L stainless steel construction withstands:

- ✔️ Temperatures up to 480°C (900°F)

- ✔️ 10,000+ PSI pressure cycles

- ✔️ pH 0-14 chemical exposure

- ✔️ 25-year corrosion resistance

Head-to-Head: Why We Beat 6 Major Brands

| Feature | Our Filters | Competitor A | Competitor B |

|---|---|---|---|

| Avg. Lifespan | 8-10 years | 3-5 years | 2-4 years |

| Price/Unit | $85-$220 | $120-$300 | $150-$400 |

Custom Solutions for Your Exact Needs

Whether you need wire mesh filters for pharmaceutical purity standards or heavy-duty mining operations, our engineers deliver:

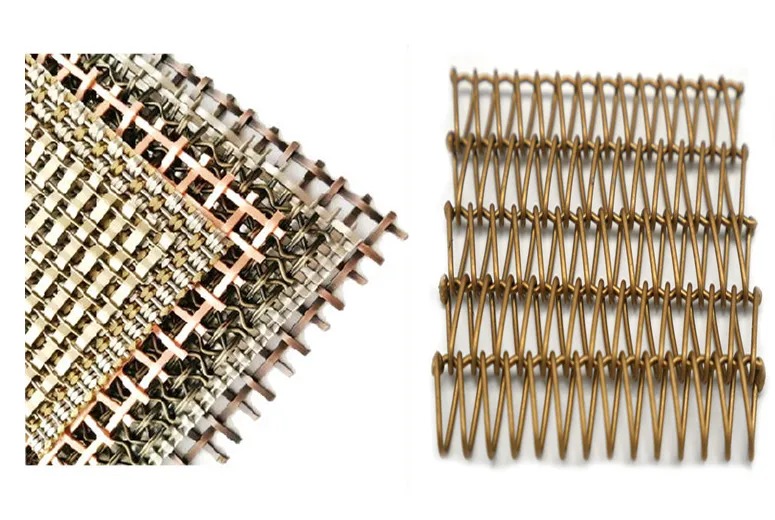

Precision Weaving

20-500 mesh counts

±0.5μm tolerance

Custom Shapes

Discs, cones, cylinders

±0.2mm dimensional accuracy

Proven Results Across Industries

✅ Automotive Client: Reduced filter replacements from 12 to 2 annually, saving $184k/year

✅ Food Processing Plant: Achieved 99.98% purity with our 400-mesh stainless steel wire mesh filter

✅ Chemical Manufacturer: Eliminated 93% of unplanned shutdowns since 2022

Ready to slash your filtration costs by 35%+?

Contact FilterPro Solutions now for your FREE customized quote!

(stainless steel wire mesh filter)

FAQS on stainless steel wire mesh filter

Q: What are the key applications of stainless steel wire mesh filters?

A: Stainless steel wire mesh filters are widely used in chemical processing, food and beverage industries, water treatment, and HVAC systems. They efficiently remove contaminants while withstanding high temperatures and pressure.

Q: How does a wire mesh filter disc differ from standard wire mesh filters?

A: A wire mesh filter disc is a pre-cut, circular version of a wire mesh filter, designed for specific equipment like pipelines or machinery. It offers targeted filtration in compact spaces, unlike standard rolls or sheets.

Q: What factors determine the lifespan of a stainless steel wire mesh filter?

A: Lifespan depends on material grade (e.g., 304 or 316 stainless steel), mesh density, exposure to corrosive substances, and cleaning frequency. Proper maintenance can extend durability significantly.

Q: Can wire mesh filters be customized for unique industrial needs?

A: Yes, wire mesh filters can be tailored in mesh size, wire diameter, layer count, and shape (e.g., discs, cylinders). Customization ensures compatibility with specific flow rates and particle retention requirements.

Q: Why choose stainless steel over other materials for wire mesh filters?

A: Stainless steel provides superior corrosion resistance, mechanical strength, and thermal stability compared to plastics or coated metals. It is also recyclable, making it ideal for sustainable and high-performance applications.