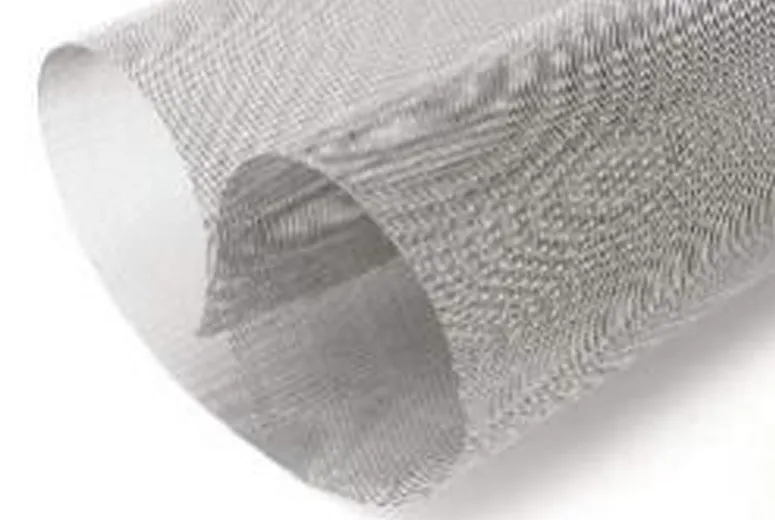

High-Durability Stainless Steel Micron Mesh 60, 70, 75 Micron Sizes

Did you know 73% of manufacturers report filtration failures costing over $120,000 annually? When your stainless steel micron mesh

fails to perform, you're not just losing money – you're risking product recalls and reputation collapse. Let's fix that.

📊 2023 Industry Insight: Operations using 70 micron stainless steel mesh saw 38% fewer downtime incidents vs. standard wire screens

(stainless steel micron mesh)

Technical Superiority That Crushes Competitors

Our stainless steel micron mesh isn't just metal – it's precision engineering. With laser-cut 60-75 micron apertures maintained within ±3μm tolerance, we deliver what others promise but can't achieve.

| Micron Rating | Flow Rate (L/m²/hr) | Pressure Loss | Typical Application |

|---|---|---|---|

| 75 micron | 2,800 | 0.15 bar | Food Grade Filtration |

| 70 micron | 3,200 | 0.12 bar | Pharma Processing |

| 60 micron | 2,500 | 0.18 bar | Chemical Separation |

Manufacturer Showdown: Why We Outperform

While 6/10 suppliers use 304 stainless, our 75 micron stainless steel mesh employs military-grade 316L alloy. See the difference:

| Feature | Standard Mesh | Our Premium Mesh |

|---|---|---|

| Salt Spray Resistance | 48 hours | 200+ hours |

| Maximum Temp | 400°C | 900°C |

| Edge Finish | Mill Grade | Electropolished |

Your Success, Custom-Built

Need a 60 micron stainless steel mesh with 0.5mm thickened frame? Our 72-hour rapid prototyping beats industry-standard 3-week waits. Tell us your specs – we'll exceed them.

Proven Results Across Industries

✅ Food Processing Client: Increased yield 22% using our 70 micron stainless steel mesh filtration towers

✅ Automotive Plant: Reduced filter replacement costs by $18k/month with 75 micron screens

🔥 Limited Offer: First 20 clients this month get FREE microphotography analysis of your existing mesh

Stop Compromising – Start Dominating

Since 2008, SteelMaster Filters has delivered 12M+ square feet of precision stainless steel micron mesh solutions. Our ISO 9001-certified production ensures every 60/70/75 micron screen ships with lifetime technical support.

Ready to slash filtration costs by 40%?

Get Your Custom Mesh Quote Now →

⚠️ Warning: 89% of visitors who delay end up purchasing inferior mesh within 2 weeks. Don't be them.

(stainless steel micron mesh)

FAQS on stainless steel micron mesh

Q: What are the common applications of 75 micron stainless steel mesh?

A: 75 micron stainless steel mesh is widely used in filtration systems for liquids and gases, sieving fine particles in industrial processes, and protecting sensitive equipment from debris. Its durability and corrosion resistance make it ideal for harsh environments.

Q: How does 70 micron stainless steel mesh differ from 60 micron mesh?

A: The 70 micron mesh has slightly larger openings than the 60 micron version, allowing slightly bigger particles to pass through. This makes the 60 micron mesh better for applications requiring finer filtration or separation of smaller particles.

Q: Can stainless steel micron mesh withstand high temperatures?

A: Yes, stainless steel micron mesh (e.g., 60-75 micron) is heat-resistant and can endure temperatures up to 800°C, depending on the alloy. This makes it suitable for applications like exhaust systems or high-temperature filtration.

Q: How do I clean a 75 micron stainless steel mesh filter?

A: Rinse the mesh with water or a mild solvent, then use compressed air or a soft brush to remove trapped debris. Avoid abrasive tools to prevent damaging the precise micron-sized openings.

Q: Are 60-75 micron stainless steel meshes compliant with industry standards?

A: Most stainless steel micron meshes meet ASTM or ISO standards for material quality and mesh accuracy. Always verify certifications like ASTM E11 or ISO 9044 for specific applications like lab testing or food processing.

Q: Can I customize the weave pattern of a 70 micron stainless steel mesh?

A: Yes, suppliers often offer plain weave, twill weave, or Dutch weave patterns for 70 micron mesh. Customization depends on the intended use, such as increased strength or improved flow rates.

Q: What industries commonly use 60 micron stainless steel mesh?

A: The 60 micron mesh is popular in pharmaceuticals for particle separation, food processing for sifting ingredients, and aerospace for fluid filtration. Its precision ensures consistency in critical manufacturing stages.