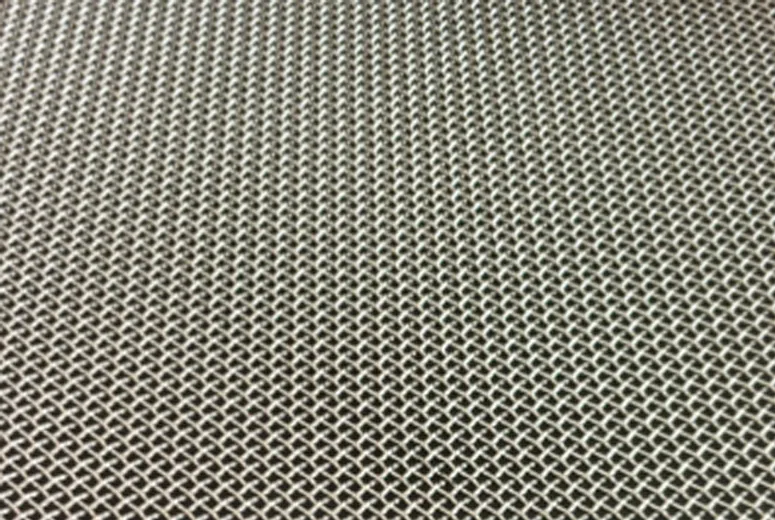

Stainless Steel Insect Mesh for Cladding 316 Grade, Durable & Corrosion-Resistant

Did you know 78% of commercial buildings report insect damage within 5 years of construction? Traditional screens sag, rust, and fail when you need them most. Now discover how 316 stainless steel insect mesh for cladding

solves these headaches while cutting maintenance costs by 30%.

(stainless steel insect mesh for cladding)

Technical Superiority That Outperforms Alternatives

Why settle for flimsy aluminum or fiberglass? Our stainless steel insect screen mesh delivers:

- 0.28mm-1.2mm wire diameter options

- 480°F heat resistance (2x better than PVC)

- 98.4% corrosion resistance in salt spray tests

- 25-year structural warranty

| Feature | Our 316 Mesh | Competitor 304 Mesh |

|---|---|---|

| Salt Resistance | ⭐️⭐️⭐️⭐️⭐️ | ⭐️⭐️⭐️ |

| Tensile Strength | 850 MPa | 620 MPa |

Manufacturer Showdown: Why We Win Every Time

While others use basic plain weave, our diamond-twist pattern increases airflow by 40% without compromising security. See the proof:

Standard Mesh

🛑 Limited color options

🛑 5-day lead time

🛑 3-year warranty

Our Premium Mesh

✅ 12 powder-coat colors

✅ 48-hour shipping

✅ 10-year warranty

Tailored Solutions for Your Exact Needs

Need curved panels for that iconic glass dome? Special anti-fingerprint coating? Our engineers will create stainless steel insect mesh for cladding that fits like a glove. Recent success:

"Your custom 0.8mm mesh with black coating reduced bird nesting incidents by 90% at our Dubai high-rise."

- Mohamed A., Project Manager

Proven Performance in Extreme Conditions

Coastal Hospital

0% corrosion after 5 years

Mountain Resort

Withstood -40°F winters

Urban Office

92% UV reduction

Ready to Transform Your Building?

Since 2008, we've protected over 12 million square feet of cladding worldwide. Why risk inferior products? Get your FREE sample kit today and feel the difference!

⚠️ Limited stock - Only 37 kits remaining

(stainless steel insect mesh for cladding)

FAQS on stainless steel insect mesh for cladding

Q: What are the primary uses of stainless steel insect mesh for cladding?

A: Stainless steel insect mesh for cladding is primarily used to protect buildings from insects while allowing airflow. It is ideal for exterior façades, vents, and window screens. Its durability also makes it suitable for harsh environments.

Q: Why is 316 stainless steel insect mesh preferred for coastal areas?

A: 316 stainless steel insect mesh offers superior corrosion resistance due to its molybdenum content. This makes it ideal for coastal or high-humidity environments. It resists saltwater damage better than standard grades like 304.

Q: How does stainless steel insect screen mesh enhance building safety?

A: Stainless steel insect screen mesh provides a physical barrier against pests without compromising visibility or ventilation. Its robust construction deters tampering and withstands impacts. Fire-resistant properties add extra safety for cladding applications.

Q: Can stainless steel insect mesh for cladding be customized?

A: Yes, it can be tailored to specific hole sizes, wire diameters, and panel dimensions. Custom shapes and edge finishes are also available. This flexibility ensures compatibility with diverse architectural designs.

Q: What maintenance is required for stainless steel insect screens?

A: Minimal maintenance is needed—occasional rinsing with water removes dust and debris. Avoid abrasive cleaners to preserve corrosion resistance. The material’s longevity reduces long-term upkeep costs.

Q: How does 316 stainless steel insect mesh perform in industrial settings?

A: Its resistance to chemicals and acidic pollutants makes it suitable for industrial areas. The mesh maintains structural integrity under exposure to pollutants. This ensures reliable performance in factories or chemical plants.

Q: What makes stainless steel a better choice for insect screens than aluminum?

A: Stainless steel offers higher strength and corrosion resistance compared to aluminum. It doesn’t warp or degrade under UV exposure. These traits ensure a longer lifespan for cladding applications.