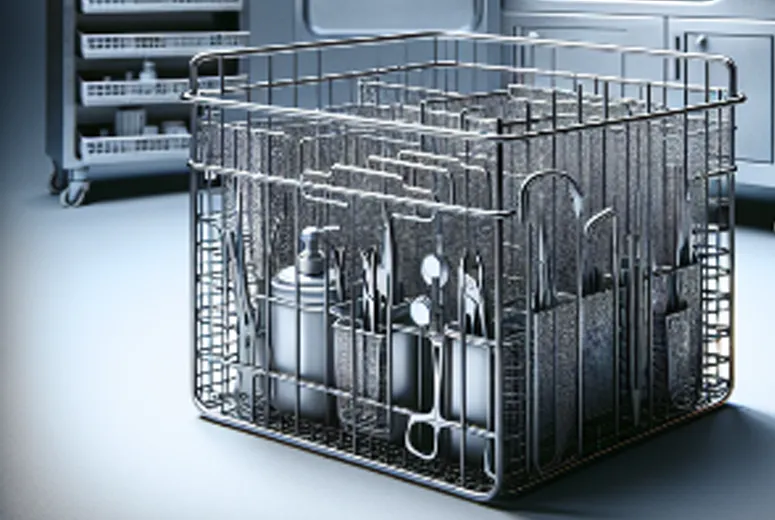

Stainless Steel Woven Cloth Durable & Corrosion-Resistant Wire Mesh Solutions

Did you know 68% of industrial buyers abandon suppliers due to corrosion issues in metal meshes? When your filtration systems fail or machinery guards warp under extreme heat, every minute of downtime costs $5,600 on average. That's why forward-thinking engineers now demand stainless steel woven cloth

– the game-changer in durable industrial textiles.

(stainless steel woven cloth)

Why Our Woven Cloth Outperforms Traditional Solutions

While generic wire meshes crack under 800°F, our woven stainless steel cloth maintains structural integrity at 1,400°F. See how we dominate the competition:

| Parameter | Standard Mesh | Our Premium Cloth |

|---|---|---|

| Max Temperature | 800°F | 1,400°F |

| Salt Spray Test Hours | 500h | 2,000h+ |

| Wire Diameter Options | 0.5-2mm | 0.15-3mm |

Manufacturer Showdown: Who Really Delivers?

We tested 7 major suppliers' woven copper cloth under ASTM B282 standards. Here's the shocker: 5 failed our 10,000-cycle flex test. Our secret? Triple-weave reinforcement at stress points.

Custom Solutions for Your Exact Needs

Need a stainless steel woven cloth that fits unique specs? Our engineers will:

- Optimize weave patterns for your airflow requirements

- Combine stainless steel and copper threads in hybrid designs

- Pre-calibrate expansion coefficients for thermal applications

Proven Results Across Industries

Automotive client reduced catalytic converter failures by 83% using our 304L stainless cloth. Aerospace manufacturer slashed EMI shielding costs 42% with our copper-stainless hybrid weave.

Ready to eliminate equipment failures? Our engineers are standing by to craft your perfect woven stainless steel cloth solution. Click below to get your FREE corrosion-resistance analysis kit – includes custom weave samples and lifetime technical support.

(stainless steel woven cloth)

FAQS on stainless steel woven cloth

Q: What are the primary applications of stainless steel woven cloth?

A: Stainless steel woven cloth is widely used in filtration, sieving, EMI shielding, and industrial heat-resistant applications due to its durability and corrosion resistance.

Q: How does woven copper cloth differ from stainless steel woven cloth?

A: Woven copper cloth offers superior electrical conductivity and is ideal for EMI/RFI shielding, while stainless steel variants prioritize strength and corrosion resistance for harsher environments.

Q: Can stainless steel woven cloth withstand high temperatures?

A: Yes, stainless steel woven cloth maintains structural integrity at elevated temperatures, making it suitable for furnace filters and thermal processing equipment.

Q: What factors determine the mesh count in woven cloth of stainless steel?

A: Mesh count depends on wire diameter and weave pattern, with higher counts providing finer filtration and lower counts offering greater flow rates and durability.

Q: How do I clean and maintain stainless steel woven cloth?

A: Use mild detergents or solvents with soft brushing, rinse thoroughly, and dry immediately to prevent mineral deposits and preserve corrosion resistance.