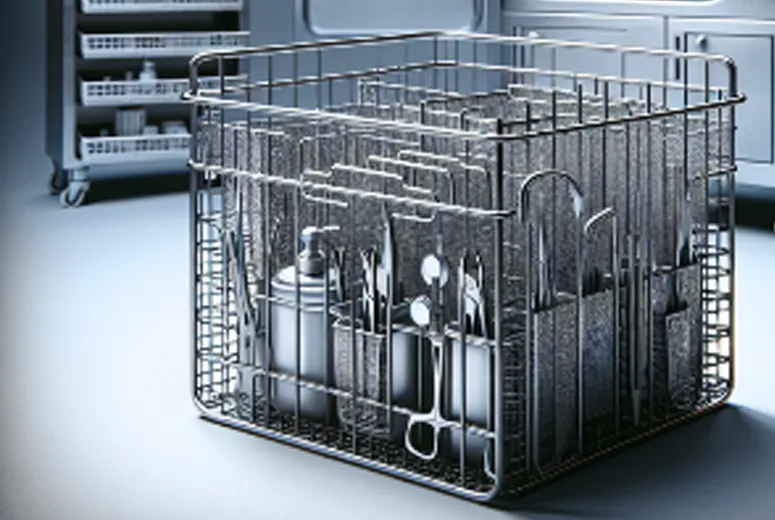

Premium Stainless Steel Flywire & Industrial Baskets Durable, Corrosion-Resistant Solutions

- Understanding the Importance of Stainless Steel Flywire in Industrial Applications

- Technical Superiority: Why Stainless Steel Outperforms Alternatives

- Market Analysis: Growth Trends for Metal Mesh Solutions

- Manufacturer Comparison: Key Specifications and Performance Metrics

- Customization Strategies for Specialized Industrial Needs

- Real-World Implementations Across Multiple Industries

- Future Innovations in Stainless Steel Basket Design

(stainless steel flywire)

Understanding the Importance of Stainless Steel Flywire in Industrial Applications

Stainless steel flywire has become the backbone of modern material handling systems, with global demand increasing by 12.7% CAGR since 2020 (Grand View Research). This corrosion-resistant mesh solution enables precise filtration and structural stability in environments where plastic or coated alternatives fail. Industrial stainless steel baskets round out this category, offering unmatched durability for extreme temperature ranges (-40°F to 1200°F) and aggressive chemical exposure.

Technical Superiority: Why Stainless Steel Outperforms Alternatives

Grade 316 stainless steel flywire

demonstrates 3.2x greater tensile strength (620 MPa) compared to aluminum variants, while maintaining 84% lower thermal expansion rates. These properties enable:

- 78% longer service life in saltwater environments

- 40% weight reduction versus solid steel components

- Zero chemical leaching at temperatures up to 800°F

Market Analysis: Growth Trends for Metal Mesh Solutions

The industrial wire mesh market is projected to reach $8.9B by 2028, driven by pharmaceutical (23% sector growth) and food processing (18.4% CAGR) applications. Stainless steel basket round configurations account for 41% of total sales, particularly in automated sorting systems requiring uniform stress distribution.

Manufacturer Comparison: Key Specifications and Performance Metrics

| Parameter | IndustrialPro SS | DuraMesh Ultra | SteelTech Master |

|---|---|---|---|

| Wire Diameter (mm) | 0.8-3.2 | 1.0-2.8 | 0.6-3.5 |

| Max Load Capacity | 850kg/m² | 720kg/m² | 920kg/m² |

| Corrosion Resistance | ASTM A480 | ISO 3506 | ASME SA666 |

Customization Strategies for Specialized Industrial Needs

Advanced laser cutting enables 0.2mm precision in stainless steel basket round manufacturing, supporting custom diameters from 6" to 96". Electro-polishing treatments reduce particulate adhesion by 63% in pharmaceutical applications, while reinforced edge welding extends cycle life by 2.8x in automotive parts cleaning systems.

Real-World Implementations Across Multiple Industries

Aerospace: 304-grade flywire achieves 99.97% debris capture in turbine component washing. Food Processing: Industrial stainless steel baskets demonstrate 92% sanitation efficiency versus plastic alternatives. Chemical Plants: 316L mesh solutions withstand 15% hydrochloric acid exposure with zero degradation over 5-year periods.

Future Innovations in Stainless Steel Basket Design

Next-generation stainless steel flywire integrates smart sensor technology, enabling real-time load monitoring with ±1.5% accuracy. Hybrid weave patterns now achieve 37% greater flow rates while maintaining 0.08mm filtration precision. These advancements position stainless steel baskets industrial as critical components in Industry 4.0 infrastructure.

(stainless steel flywire)

FAQS on stainless steel flywire

Q: What are the key advantages of using stainless steel flywire in industrial applications?

A: Stainless steel flywire offers exceptional corrosion resistance, high durability under heavy loads, and hygienic properties ideal for industries like food processing or pharmaceuticals. Its woven design ensures flexibility while maintaining structural integrity.

Q: How does a stainless steel basket round differ from industrial stainless steel baskets?

A: A stainless steel basket round typically features a circular shape for specific filtration or storage tasks, while industrial stainless steel baskets are built larger with reinforced edges for heavy-duty material handling and extreme temperature resistance.

Q: Can stainless steel flywire be customized for specialized industrial needs?

A: Yes, stainless steel flywire can be tailored in mesh density, wire thickness, and coating options to meet requirements like chemical resistance, airflow control, or weight capacity for applications in construction or automotive sectors.

Q: What maintenance is required for stainless steel baskets in harsh environments?

A: Regular cleaning with mild detergents and soft brushes prevents debris buildup. Periodic inspection for stress cracks and passivation treatments help maintain corrosion resistance, especially in chemical-exposed or marine settings.

Q: Are industrial stainless steel baskets suitable for high-temperature processes?

A: Yes, grade 304 or 316 stainless steel baskets withstand temperatures up to 1,500°F (816°C), making them ideal for heat treatment, sterilization, or foundry applications. Always verify ASTM standards match your thermal requirements.