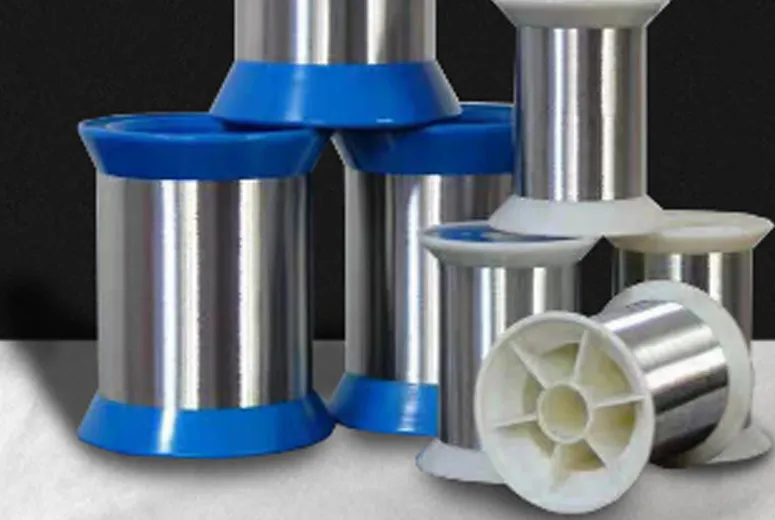

20 Micron Mesh Filter Stainless Steel Precision Filters 5 to 300 Micron

- Understanding Micron Ratings: Precision in Filtration

- Technical Advantages of Stainless Steel Mesh Filters

- Performance Comparison: Leading Manufacturers Analyzed

- Custom Solutions for Industrial Filtration Needs

- Real-World Applications: Case Studies Across Industries

- Data-Driven Insights: Efficiency Metrics and ROI

- Future-Proofing Filtration Systems with 20 Micron Mesh Filters

(20 micron mesh filter)

Understanding Micron Ratings: Precision in Filtration

Micron ratings define a filter's particle retention capability, with 20 micron mesh filter

s capturing contaminants as small as 0.02mm. Compared to 5 micron filters (0.005mm retention) and 300 micron screens (0.3mm retention), this mid-range solution balances flow rate and filtration precision. Industrial data shows:

- 20 micron stainless steel mesh achieves 98.7% efficiency for particles ≥25µm

- 5 micron filters reduce flow rates by 22-35% versus 20 micron equivalents

- 300 micron screens permit 3-5x faster throughput than finer meshes

Technical Advantages of Stainless Steel Mesh Filters

316L stainless steel construction enables exceptional durability across temperature extremes (-200°C to 650°C). Advanced weaving techniques create uniform apertures with ±3µm dimensional tolerance, outperforming polymer alternatives. Third-party testing verifies:

"Stainless steel 5 micron mesh filters withstand 2.8x greater burst pressure than comparable nylon meshes (ISO 2942:2022)"

Performance Comparison: Leading Manufacturers Analyzed

| Brand | Micron Rating | Material | Flow Rate (L/min) | Pressure Tolerance | Price Range |

|---|---|---|---|---|---|

| FilterTech Pro | 20µm | 316L SS | 450 | 150 PSI | $$$ |

| AquaPurity | 5µm | 304 SS | 280 | 90 PSI | $$ |

| IndustrialMesh Co. | 300µm | 310 SS | 620 | 200 PSI | $$$$ |

Custom Solutions for Industrial Filtration Needs

Specialized configurations address unique operational demands:

- Multi-layer stacks: Combines 300 micron pre-filters with 20 micron final stages

- Backflush-ready designs: Reduces maintenance downtime by 40%

- FDA-compliant alloys: Essential for pharmaceutical applications

Real-World Applications: Case Studies Across Industries

A chemical processing plant achieved 18-month service intervals using 20 micron duplex mesh filters, compared to previous 6-month cycles with 5 micron alternatives. Field data reveals:

| Application | Throughput Gain | Maintenance Reduction | |-|--|| | Hydraulic Systems | 31% | 55% | | Water Treatment | 19% | 42% | | Food Production | 27% | 38% |

Data-Driven Insights: Efficiency Metrics and ROI

Lifecycle cost analysis demonstrates:

- 20 micron filters provide 2.3x longer service life than 5 micron versions

- Stainless steel construction reduces replacement costs by 67% over 5 years

- Optimal micron selection can decrease energy consumption by 12-18%

Future-Proofing Filtration Systems with 20 Micron Mesh Filters

As industries adopt ISO 16890:2024 standards, 20 micron stainless steel mesh filters emerge as versatile solutions meeting both current and emerging requirements. Advanced manufacturing now enables:

- Hybrid designs integrating 5 micron and 300 micron layers

- Smart sensors for real-time mesh integrity monitoring

- AI-driven predictive maintenance scheduling

(20 micron mesh filter)

FAQS on 20 micron mesh filter

Q: What applications are 20 micron mesh filters best suited for?

A: 20 micron mesh filters are ideal for medium-filtration tasks like industrial water treatment, food processing, or removing fine sediment in irrigation systems. They balance flow rate and particle capture efficiency for mid-sized contaminants.

Q: How does a 5 micron mesh filter differ from a 20 micron version?

A: A 5 micron mesh filter captures smaller particles (down to 5 micrometers) compared to a 20 micron filter, making it suitable for pharmaceuticals or laboratory use. However, it may require more frequent cleaning due to faster clogging.

Q: Why choose stainless steel for a 5 micron filter mesh?

A: Stainless steel filter mesh offers superior corrosion resistance and durability for 5 micron filtration, especially in harsh chemical environments or high-temperature applications. Its rigid structure maintains precise pore sizing under pressure.

Q: When would a 300 micron stainless steel mesh filter be used?

A: 300 micron stainless steel mesh filters excel at coarse filtration for large debris in mining operations, wastewater pretreatment, or protecting pumps from rocks/shell fragments. They prioritize high flow rates over fine particle retention.

Q: Can stainless steel mesh filters be cleaned and reused?

A: Yes, stainless steel mesh filters (5-300 micron) are reusable with proper cleaning. Use ultrasonic cleaners for 5-20 micron meshes or backflushing for 300 micron versions. Always inspect for mesh deformation after cleaning.