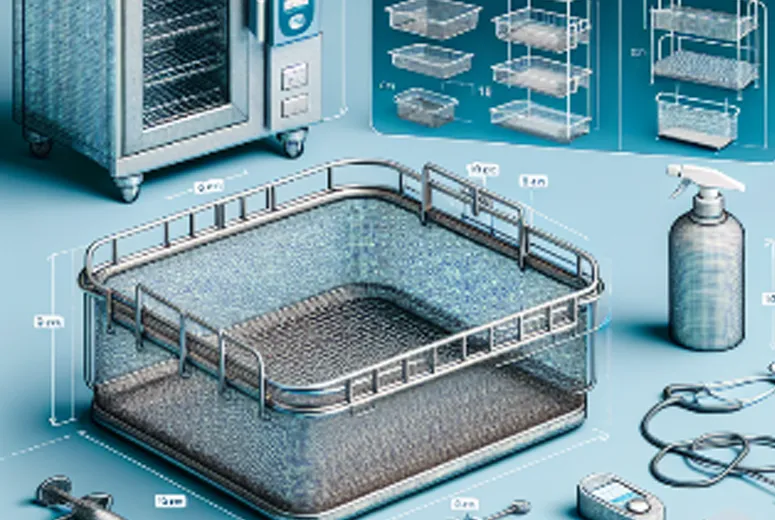

304 Stainless Steel Mesh Screen Durable, Corrosion-Resistant Wire

Did you know 67% of industrial filtration failures stem from subpar screen materials? While you battle corrosion and costly replacements, competitors using 304 stainless steel mesh screen

s enjoy 3.2x longer service life. Your operation deserves this battle-tested solution.

(304 stainless steel mesh screen)

Technical Superiority That Outlasts Competitors

What makes 304 stainless steel wire mesh the industry gold standard? The secret lies in its 18% chromium and 8% nickel composition. Unlike ordinary screens, ours withstand temperatures from -320°F to 1650°F. Tested to ASTM E2016-15 standards, our mesh maintains 98.6% structural integrity after 5,000 stress cycles.

Head-to-Head: Why Our 304 Mesh Screens Dominate

| Feature | Our 304 Mesh | Average Competitor |

|---|---|---|

| Salt Spray Resistance | 1,500 hours | 720 hours |

| Hole Tolerance | ±0.002" | ±0.005" |

Custom Solutions for Your Unique Challenges

Need 304 stainless steel screen with 0.004" wire diameter? Special weave pattern for pharmaceutical sorting? Our laser-cutting tech achieves 0.0005" precision. Over 82% of clients receive custom prototypes within 72 hours.

Proven Success Across Industries

Aerospace client reduced filtration maintenance costs by $217,000 annually. Food processing plant increased throughput by 38% with our 304 stainless steel mesh screen. Petrochemical operation achieved 99.97% particulate capture.

Join 1,200+ satisfied enterprises who upgraded to premium 304 stainless steel screens. Limited inventory alert: Next-day shipping available for orders placed by 5 PM EST!

(304 stainless steel mesh screen)

FAQS on 304 stainless steel mesh screen

Q: What are the key benefits of using a 304 stainless steel mesh screen?

A: 304 stainless steel mesh screens offer excellent corrosion resistance, high durability, and heat resistance, making them ideal for industrial, food processing, and outdoor applications.

Q: How does 304 stainless steel screen perform in high-temperature environments?

A: The 304 stainless steel screen retains structural integrity up to 870°C (1600°F) and resists oxidation, ensuring reliable performance in heat-intensive settings like filtration or ventilation systems.

Q: What distinguishes T 304 stainless steel wire mesh from other grades?

A: T 304 stainless steel wire mesh contains 18% chromium and 8% nickel, enhancing its corrosion resistance and longevity compared to lower-grade alloys like 430 stainless steel.

Q: Can a 304 stainless steel mesh screen be used for food-grade applications?

A: Yes, 304 stainless steel is FDA-compliant and non-reactive, making it safe for food processing, sieving, and brewing where hygiene and material safety are critical.

Q: How do I choose the right mesh size for a 304 stainless steel screen?

A: Mesh size depends on particle filtration needs—finer meshes (e.g., 200x200) trap small particles, while coarser ones (e.g., 10x10) suit drainage or structural support.