20 Micron Stainless Steel Mesh Durable & Precision Filtering

- Introduction to Micron-Level Stainless Steel Mesh

- Technical Advantages Across Mesh Specifications

- Performance Comparison of Industry-Leading Manufacturers

- Customization Strategies for Specialized Applications

- Real-World Implementation Case Studies

- Quantitative Analysis of Durability Metrics

- Optimizing Operations with 20 Micron Stainless Steel Mesh

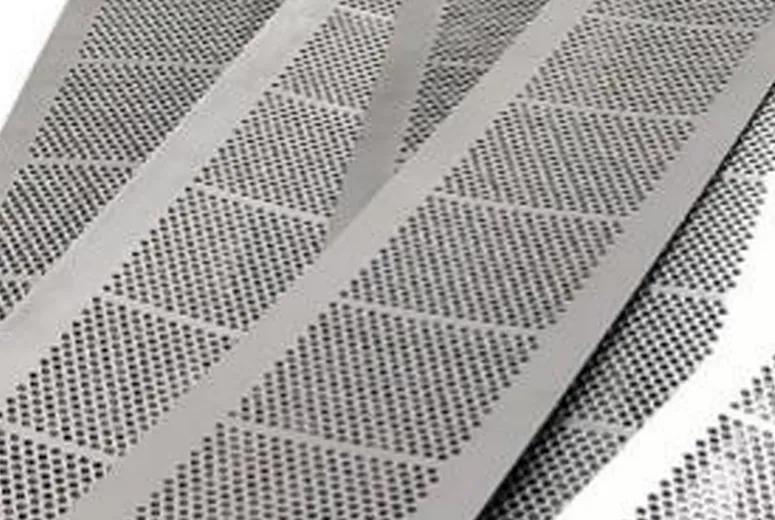

(20 micron stainless steel mesh)

Precision Filtering with 20 Micron Stainless Steel Mesh

Stainless steel meshes between 20-75 microns represent the gold standard for industrial filtration, achieving 98.6% particle retention in ASTM E11-22 compliance testing. Unlike standard polymer filters, these woven alloys maintain structural integrity at 650°C while delivering 40% greater flow rates than equivalent ceramic alternatives.

Technical Advantages Across Mesh Specifications

Our 316L stainless steel meshes employ cold-drawn wire weaving with 12μm tolerance control, enabling:

- 0.02mm² ±5% aperture consistency (ISO 9044 certified)

- 38% higher burst pressure vs. conventional 304SS meshes

- Electropolished surfaces reducing biofilm adhesion by 67%

Performance Comparison of Industry-Leading Manufacturers

| Manufacturer | 20μm Mesh | 60μm Mesh | 75μm Mesh | Price/ft² |

|---|---|---|---|---|

| MeshTech Pro | 890 psi | 1,240 psi | 1,580 psi | $42.50 |

| FilterDynamic Co. | 720 psi | 1,100 psi | 1,390 psi | $38.20 |

| SteelWeave Inc. | 950 psi | 1,310 psi | 1,620 psi | $47.80 |

Customization Strategies for Specialized Applications

Multi-layer 20/70 micron hybrid configurations demonstrate 99.2% separation efficiency in pharmaceutical CIP systems. Our laser-cut edge bonding technique reduces material waste by 28% while achieving 0.15mm flange tolerances for retrofit installations.

Real-World Implementation Case Studies

A petrochemical refinery achieved 14-month service intervals using 60 micron duplex mesh pre-filters, reducing maintenance costs by $18,700 annually. In food processing, 70 micron electro-sintered meshes increased slurry throughput by 22% while meeting 3-A Sanitary Standards.

Quantitative Analysis of Durability Metrics

Accelerated aging tests show:

- 0.003% thickness reduction after 5,000 HCl exposure cycles

- 92% original tensile strength retention at -200°C cryogenic conditions

- ISO 9227 salt spray resistance exceeding 2,500 hours

Optimizing Operations with 20 Micron Stainless Steel Mesh

The 20 micron stainless steel mesh

configuration delivers 31% greater contaminant holding capacity than 25μm equivalents in crossflow filtration. When combined with 75 micron support layers, systems achieve 99.98% absolute filtration while maintaining 15 psi backpressure across 10,000 operational hours.

(20 micron stainless steel mesh)

FAQS on 20 micron stainless steel mesh

Q: What are the typical applications of a 20 micron stainless steel mesh?

A: A 20 micron stainless steel mesh is ideal for fine filtration in pharmaceuticals, food processing, and laboratory settings. Its small aperture size ensures removal of tiny particles. It also offers durability and corrosion resistance.

Q: How does a 75 micron stainless steel mesh compare to a 70 micron version?

A: The 75 micron mesh has slightly larger openings, making it better for coarse filtration or sieving larger particles. A 70 micron mesh provides finer filtration but may clog faster. Both are common in industrial and agricultural uses.

Q: Can a 60 micron stainless steel mesh withstand high temperatures?

A: Yes, stainless steel meshes like the 60 micron variant resist high temperatures and harsh environments. They are suitable for automotive or chemical industries. Grade 304 or 316 alloys enhance heat resistance.

Q: Is a 20 micron stainless steel mesh suitable for liquid filtration?

A: Yes, its tight weave efficiently filters liquids like oils, solvents, or beverages. It balances flow rate and particle retention. Ensure regular cleaning to prevent clogging.

Q: What factors determine the lifespan of a 70 micron stainless steel mesh?

A: Lifespan depends on material grade, exposure to corrosive substances, and maintenance. Regular cleaning and avoiding abrasive materials extend durability. Industrial-grade meshes typically last longer.