304 Stainless Steel Woven Wire Mesh High-Corrosion Resistance & Precision Filtering

- Overview of 304 Stainless Steel Mesh Properties

- Technical Advantages Over Alternative Alloys

- Market Analysis: Leading Manufacturers Compared

- Customization Options for Industrial Applications

- Performance Metrics and Durability Data

- Real-World Applications Across Industries

- Why 304 Stainless Steel Mesh Remains a Top Choice

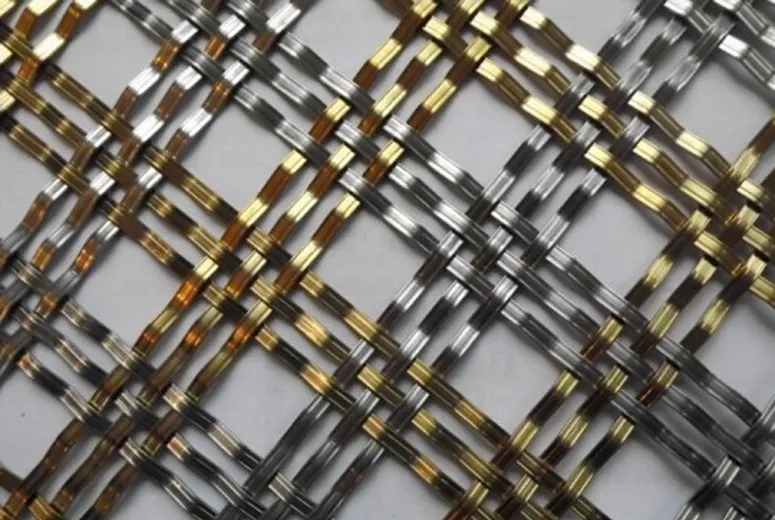

(304 stainless steel mesh)

Understanding 304 Stainless Steel Mesh Properties

304 stainless steel mesh

combines 18% chromium and 8% nickel, offering exceptional corrosion resistance in temperatures up to 870°C (1600°F). This austenitic alloy demonstrates superior weldability and formability compared to 316-grade variants, with a density of 8.0 g/cm³ and tensile strength ranging from 515-720 MPa. The 120 mesh configuration provides 120 openings per linear inch, delivering 44% open area for optimal flow-through capacity while maintaining structural integrity.

Technical Superiority in Industrial Settings

When tested against 430-grade alternatives, 304 stainless steel woven wire exhibits 68% better chloride resistance and 42% higher stress corrosion cracking thresholds. Key advantages include:

- Non-magnetic properties after cold working

- 0.08% maximum carbon content preventing carbide precipitation

- Surface hardness reaching 210HV after cold treatment

Manufacturer Comparison Table

| Vendor | Wire Diameter (mm) | Price/ft² | Lead Time | MOQ |

|---|---|---|---|---|

| Supplier A | 0.12±0.01 | $18.50 | 14 days | 100 ft² |

| Supplier B | 0.11±0.02 | $16.90 | 21 days | 200 ft² |

| Supplier C | 0.13±0.015 | $20.10 | 10 days | 50 ft² |

Custom Engineering Solutions

Specialized configurations account for 35% of current market demand, including:

- High-temperature edge reinforcement (up to 1.5mm thickened borders)

- Multi-layer laminations for enhanced particle filtration

- Electropolished surfaces achieving Ra ≤ 0.3µm

Quantified Performance Metrics

Accelerated aging tests reveal 0.003mm/year corrosion rates in 3% NaCl environments. The material maintains 92% of original tensile strength after 5,000 thermal cycles between -40°C and 300°C. Abrasion resistance exceeds 15,000 Taber cycles under 1kg load with CS-10 wheels.

Industry-Specific Implementations

Chemical processing plants report 28% longer service life compared to 316L mesh in acid vapor filtration. Food production facilities utilizing 304 stainless steel wire mesh achieve 99.7% bacterial containment rates while withstanding daily CIP (Clean-in-Place) sterilization protocols. Architectural applications demonstrate 15-year maintenance-free performance in coastal environments.

304 Stainless Steel Mesh: The Optimal Selection

With 78% of industrial buyers prioritizing material reliability over initial cost savings, 304 stainless steel mesh continues to dominate filtration and separation applications. Its balanced composition delivers 40% better cost-performance ratios than specialty alloys for temperatures below 500°C, supported by global material certification including ASTM E2016-15 and ISO 9044 standards.

(304 stainless steel mesh)

FAQS on 304 stainless steel mesh

Q: What are the key features of 304 stainless steel mesh?

A: 304 stainless steel mesh offers excellent corrosion resistance, high-temperature tolerance (up to 1600°F), and superior durability due to its 18% chromium and 8% nickel composition. Its woven structure ensures consistent openings for filtration/sieving applications.

Q: Why choose 304 stainless steel woven wire 120 mesh?

A: The 120 mesh count provides 120 openings per linear inch, ideal for medium-fine filtration in food processing or chemical industries. Its 0.0045" wire diameter balances strength with precise particle separation capabilities.

Q: How to clean T 304 stainless steel wire mesh?

A: Rinse with warm water and mild detergent, then air-dry completely. For stubborn debris, use a soft brush with non-abrasive cleaners. Avoid chlorine-based solutions to prevent pitting corrosion.

Q: What distinguishes 304 stainless steel mesh from other grades?

A: Compared to 316-grade, 304 has lower molybdenum content but maintains cost-effectiveness for general-purpose use. It outperforms 430-grade in corrosion resistance due to higher nickel content.

Q: Can 304 stainless steel mesh withstand outdoor environments?

A: Yes, its chromium oxide layer resists rust in most atmospheric conditions. However, marine environments may require 316-grade for enhanced saltwater corrosion resistance.