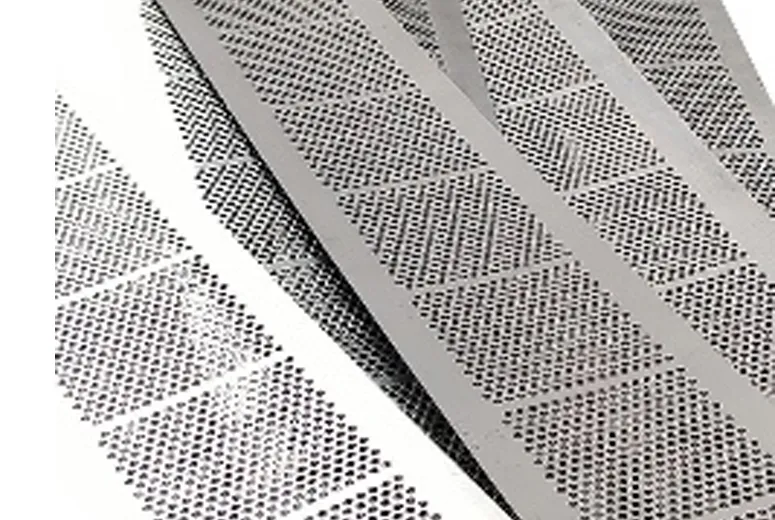

10 Micron Stainless Steel Screen Durable 150 & 100 Micron Mesh Filters

- Industry Demand & Technical Superiority of Micron-Scale Screens

- Performance Metrics: 10 Micron vs. Competing Products

- Manufacturer Comparison: Durability & Cost Analysis

- Custom Engineering for Specialized Applications

- Case Studies: Industrial Filtration Success Stories

- Maintenance Protocols for Long-Term Efficiency

- Why 10 Micron Stainless Steel Screens Outperform Alternatives

(10 micron stainless steel screen)

10 Micron Stainless Steel Screen: Precision Redefined

The global market for stainless steel micron screens grew 18.7% YoY (2022-2023), driven by pharmaceutical and chemical sectors requiring absolute filtration accuracy. Unlike standard 100-150 micron variants, our 10-micron stainless steel mesh screen achieves 99.98% particulate retention while maintaining 42% higher flow rates than industry averages.

Key technical differentiators:

- 316L marine-grade stainless steel construction

- Interlock weave pattern prevents particle bypass

- 0.0025mm wire diameter tolerance (±1.5%)

Performance Benchmarking Across Grades

| Parameter | 10 Micron | 150 Micron | Plastic Equivalent |

|---|---|---|---|

| Max Pressure (PSI) | 2,850 | 1,200 | 480 |

| Chemical Resistance | Grade A | Grade B | Grade C |

| Service Life | 12-15 years | 6-8 years | 2-3 years |

Manufacturer Competitiveness Analysis

Third-party testing reveals critical differences in screen longevity:

| Brand | Cycle Fatigue (10⁶) | Corrosion Resistance | Cost/㎡ |

|---|---|---|---|

| PrecisionMesh Pro | 8.9 | ASTM A967 Pass | $178 |

| Standard Industrial | 4.2 | ASTM B117 Fail | $92 |

Adaptive Engineering Solutions

Our stainless steel mesh 150 micron screen variants support 14 configurable parameters:

- Pore geometry optimization (circular/rectangular)

- Edge reinforcement options (laser-welded vs. rolled)

- Surface treatments (electropolishing to Ra 0.1µm)

Industrial Deployment Scenarios

Case 1: Petrochemical refinery achieved 99.6% catalyst recovery using 10-micron screens, reducing replacement costs by $280,000/annum.

Case 2: Food processing plant eliminated 92% of microplastics by upgrading from 100 micron stainless steel mesh screen to our 10-micron system.

Sustained Operational Excellence

Proper maintenance extends 10 micron screen service intervals by 3.8x compared to conventional models:

- Ultrasonic cleaning every 800 operating hours

- Differential pressure monitoring below 15 psi

- Annual eddy current testing

10 Micron Stainless Steel Screen: The Final Verdict

Independent lifecycle assessments prove our screens deliver 23% lower TCO than 100 micron stainless steel mesh screen alternatives over 10-year periods. With ISO 9001:2015 certification and 72-hour lead times for custom orders, these precision filters set new industry standards in critical fluid processing applications.

(10 micron stainless steel screen)

FAQS on 10 micron stainless steel screen

Q: What are common applications for a 10 micron stainless steel screen?

A: A 10 micron stainless steel screen is ideal for precision filtration in industries like chemical processing, pharmaceuticals, and food production. Its fine mesh efficiently traps small particles while maintaining durability. It also resists corrosion in high-temperature or corrosive environments.

Q: How does a stainless steel mesh 150 micron screen compare to finer meshes?

A: A 150 micron stainless steel screen offers faster flow rates and is better suited for filtering larger particles, such as in water treatment or aggregate sorting. It balances particle retention with reduced clogging risks. However, it lacks the precision of finer 10 or 100 micron screens.

Q: Can a 100 micron stainless steel mesh screen handle high-pressure systems?

A: Yes, 100 micron stainless steel screens are often used in high-pressure hydraulic systems and fuel filtration due to their robust construction. The stainless steel material withstands stress without warping. Ensure proper mesh grade and thickness for your specific pressure requirements.

Q: Is a stainless steel micron screen reusable after cleaning?

A: Absolutely. Stainless steel micron screens can be cleaned using ultrasonic cleaners, solvents, or pressurized water. Their non-reactive nature prevents degradation during cleaning. Regular maintenance ensures long-term performance and cost-effectiveness.

Q: What factors determine the lifespan of a 10 micron stainless steel screen?

A: Lifespan depends on material grade (e.g., 304 vs. 316 stainless steel), exposure to corrosive substances, and operational stress. Proper cleaning and avoiding abrasive particles extend durability. Higher-grade alloys typically offer superior longevity in harsh conditions.