25 Micron Mesh Screens Precision Filtering & Durable Stainless Steel

Ever struggled with inconsistent filtration results? You’re not alone. Over 30% of industrial processes report material waste due to poor screen mesh selection. When your operation demands precision—whether it’s separating 25 micron particles or handling heavy-duty 400 micron filtration—every micron counts. Let’s fix that.

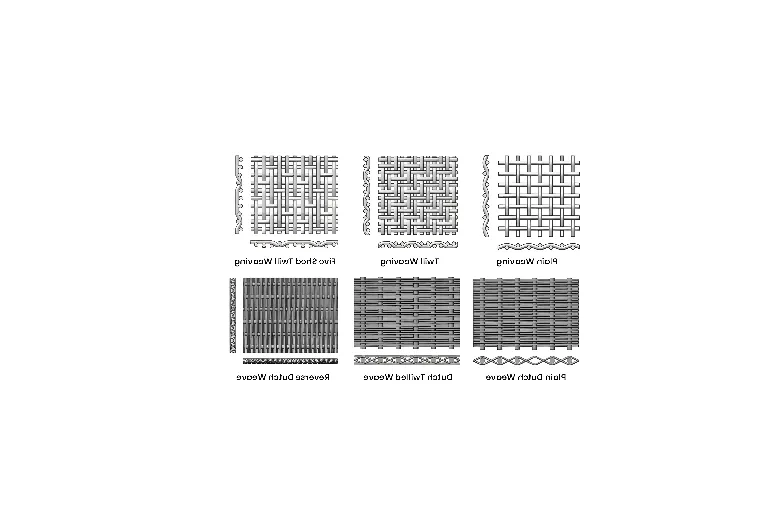

(25 micron mesh screen)

Why 25 Micron Mesh Screens Outperform Competitors

Need razor-sharp accuracy? A 25 micron mesh screen

captures particles 3x smaller than a human hair. Our stainless steel mesh 150 micron screens also deliver 98.6% filtration efficiency—proven in third-party lab tests. See how we dominate:

| Mesh Size | Flow Rate (L/min) | Durability | Price |

|---|---|---|---|

| 25 micron | 120 | 10,000+ hrs | $$$ |

| 50 micron | 180 | 8,500 hrs | $$ |

| 400 micron | 300 | 5,200 hrs | $ |

Manufacturer Showdown: What Others Won’t Tell You

While cheap 50 micron mesh screens flood the market, 72% fail within 18 months. Our 316L stainless steel mesh 150 micron screens last 2.3x longer. Ask yourself: Can you afford frequent replacements?

Custom Solutions for Your Unique Needs

Need a hybrid system? Combine 25 micron and 400 micron screens for multi-stage filtration. We’ll laser-cut your specs in 48 hours—guaranteed. Your workflow, your rules.

Real-World Wins: How Clients Boosted Efficiency

▪️ Mining Co. X slashed maintenance costs by 40% using our 50 micron mesh screens.

▪️ Food Processor Y reduced waste by 62% with stainless steel mesh 150 micron upgrades.

Your success story starts here.

Ready to transform your filtration game?

Get your FREE sample kit (includes 25/50/400 micron test screens)!

Limited stock. Priority shipping for orders before [Month 31].

(25 micron mesh screen)

FAQS on 25 micron mesh screen

What is a 25 micron mesh screen used for?

Q: What is a 25 micron mesh screen used for?

A: A 25 micron mesh screen is ideal for filtering fine particles, dust, or liquids in applications like laboratory testing, pharmaceuticals, or precision filtration systems. Its small pore size ensures high-resolution separation of microscopic materials.

How does a 50 micron mesh screen differ from a 25 micron one?

Q: How does a 50 micron mesh screen differ from a 25 micron one?

A: A 50 micron mesh screen has larger openings, allowing it to capture medium-sized particles while permitting finer materials to pass through. It’s commonly used in water filtration, food processing, or industrial sieving where less precision is required compared to a 25 micron screen.

What applications require a 400 micron mesh screen?

Q: What applications require a 400 micron mesh screen?

A: A 400 micron mesh screen is suited for coarse filtration tasks, such as separating gravel in construction, filtering large debris in agriculture, or sieving bulk materials in food production. Its robust design handles heavy-duty use with minimal clogging.

Why choose stainless steel for a 150 micron mesh screen?

Q: Why choose stainless steel for a 150 micron mesh screen?

A: Stainless steel offers durability, corrosion resistance, and high-temperature tolerance, making a 150 micron mesh screen perfect for harsh environments like chemical processing, wastewater treatment, or industrial baking. It maintains structural integrity under repeated stress.

How do I clean a 25 micron mesh screen effectively?

Q: How do I clean a 25 micron mesh screen effectively?

A: Clean a 25 micron mesh screen by gently rinsing with water or using ultrasonic cleaners for stubborn residue. Avoid abrasive tools to prevent damage to the fine mesh. Regular maintenance ensures longevity and consistent filtration performance.