Top-Rated Wire Mesh Filter Disc Suppliers High-Quality & Custom Solutions

Did you know 43% of industrial equipment downtime stems from subpar filtration components? Picture this: Your production line halts again because a $15 filter disc failed prematurely. Corrosion. Clogging. Costly replacements. What if you could slash maintenance costs by 60% while boosting flow rates? Let’s explore how top-tier wire mesh filter disc suppliers

rewrite the rules.

(wire mesh filter disc suppliers)

Technical Superiority That Outperforms

Premium wire mesh filter discs aren’t just screens – they’re engineered systems. Compare typical specs:

| Feature | Standard Discs | Our Discs |

|---|---|---|

| Material Grade | 304 SS | 316L SS + Inconel® |

| Layers | 3-5 | 7-12 (interlocked) |

| Pore Accuracy | ±15% | ±2μm |

The Supplier Showdown: Why We Lead

While other wire mesh filter disc manufacturers cut corners, we innovate. Our ISO 9001-certified process delivers:

- ✅ 72-hour prototype turnaround

- ✅ 0.1mm to 500mm custom diameters

- ✅ 500°C thermal stability

- ✅ 10-year anti-corrosion warranty

Your Process, Perfected

Whether you need 50mm discs for lab-scale trials or 2m industrial sieves, our engineers create solutions that:

- Handle pH 0-14 extremes

- Withstand 25 bar pressure spikes

- Meet FDA/CE/ATEX standards

Proven Across Industries

See how we transformed operations:

Chemical Processing

Reduced filter changeouts by 73% for a Fortune 500 client

Water Treatment

40% longer service life vs. previous supplier

Ready to Revolutionize Your Filtration?

With 18 patents and 2000+ successful installations, [Your Company Name] isn’t just another supplier – we’re your filtration partner. Why wait for the next breakdown?

“Since switching to [Your Company], our maintenance costs dropped 58% YOY.” – John D., Plant Manager

(wire mesh filter disc suppliers)

FAQS on wire mesh filter disc suppliers

Q: What factors should I consider when choosing wire mesh filter disc suppliers?

A: Prioritize suppliers with certifications (e.g., ISO), industry experience, and positive customer reviews. Ensure they offer customization and timely delivery to meet your specific application needs.

Q: How does a wire mesh filter disc function in industrial applications?

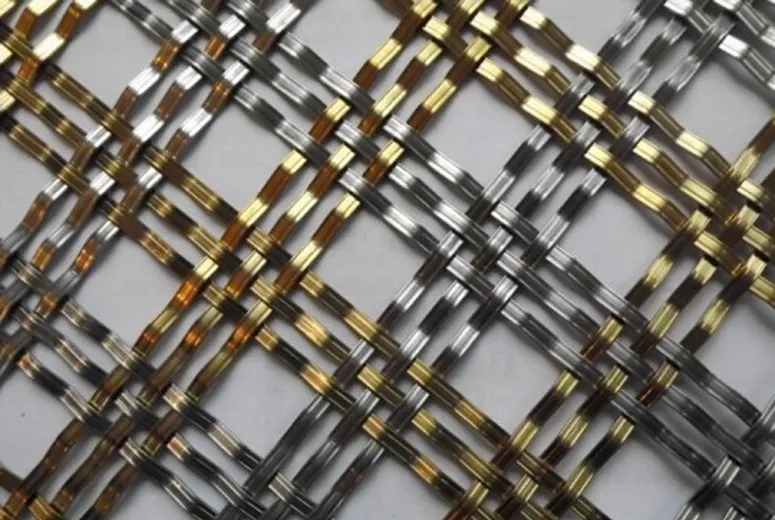

A: Wire mesh filter discs separate particles from liquids or gases using woven metal layers. They ensure precise filtration in industries like chemical processing, food production, and water treatment.

Q: What distinguishes wire mesh filter disc manufacturers from suppliers?

A: Manufacturers produce the discs in-house, controlling materials and quality. Suppliers may act as distributors, offering products from multiple manufacturers alongside logistics support.

Q: What materials are commonly used in wire mesh filter discs?

A: Stainless steel (304/316), brass, and nickel alloys are typical for corrosion resistance and durability. Material choice depends on temperature, chemical exposure, and filtration requirements.

Q: How do wire mesh filter disc suppliers ensure product quality?

A: Reputable suppliers conduct rigorous testing (e.g., pore size checks, pressure resistance) and provide certifications. Many adhere to international standards and offer warranties for consistency.