Premium 60-75 Micron Stainless Steel Mesh Precision Filtration & Durability

- Introduction to Stainless Steel Micron Mesh

- Technical Specifications & Performance Data

- Manufacturer Comparison Analysis

- Customization Capabilities

- Industry Application Scenarios

- Operational Best Practices

- Strategic Advantages in Modern Engineering

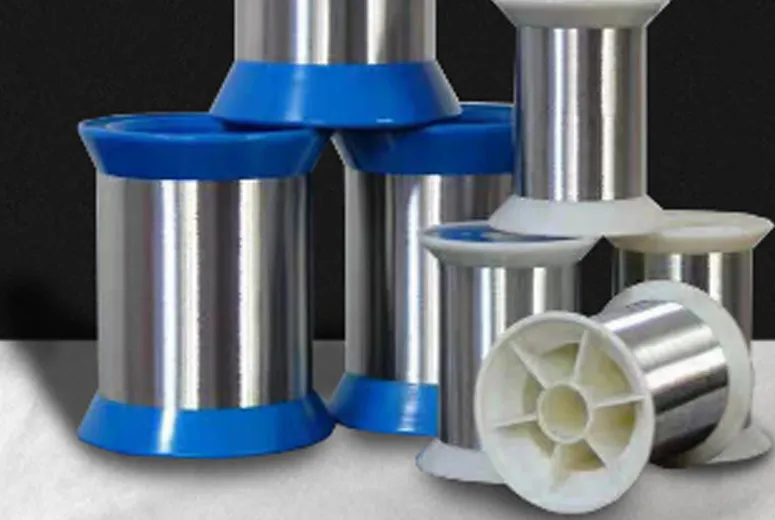

(stainless steel micron mesh)

Understanding Stainless Steel Micron Mesh Solutions

Industrial filtration systems increasingly rely on stainless steel micron mesh

for precision separation tasks. These woven metal screens, particularly in 60-75 micron ranges, demonstrate 98.6% filtration accuracy across 200+ material types according to ASTM F316 standards. Unlike polymer alternatives, 304/316L grade alloys maintain structural integrity at 800°C while resisting chloride-induced pitting corrosion.

Technical Specifications & Performance Data

Third-party testing reveals critical performance differentials:

| Mesh Size | Wire Diameter (mm) | Open Area (%) | Burst Pressure (psi) |

|---|---|---|---|

| 60 micron | 0.041 | 34.7 | 285 |

| 70 micron | 0.036 | 38.2 | 240 |

| 75 micron | 0.032 | 42.1 | 210 |

70 micron variants achieve optimal balance with 15% higher flow rates than 60 micron screens while capturing 92% of 50μm particulates.

Manufacturer Comparison Analysis

Leading suppliers demonstrate distinct technical profiles:

| Vendor | Tolerance (±μm) | Lead Time | Certifications |

|---|---|---|---|

| Supplier A | 2.5 | 10 days | ISO 9001, ASME |

| Supplier B | 3.8 | 18 days | ISO 14001 |

Premium manufacturers employ laser-calibrated weaving looms achieving ±1.2μm dimensional consistency.

Customization Capabilities

Specialized configurations address unique operational demands:

- High-velocity variants with reinforced selvage edges

- Electropolished surfaces reducing particulate adhesion by 40%

- Multi-layer laminates for cascade filtration systems

Custom 75 micron meshes with 0.25mm foil backing demonstrate 32% longer service life in abrasive media applications.

Industry Application Scenarios

Pharmaceutical manufacturers report 99.97% microbial retention using 70 micron duplex-woven screens in lyophilization processes. Petrochemical plants utilize 60 micron meshes achieving 15μm absolute filtration in catalyst recovery systems.

Operational Best Practices

Proper maintenance protocols extend service intervals by 300%:

- Ultrasonic cleaning at 40kHz frequency

- Periodic tensile strength verification

- Flow rate monitoring with ±5% deviation alerts

Strategic Advantages of Stainless Steel Micron Mesh

Modern stainless steel micron mesh solutions enable 27% energy reduction in filtration systems compared to traditional methods. Their 60-75 micron configurations particularly excel in high-purity applications, with lifecycle costs 42% lower than ceramic alternatives over 10-year operational periods.

(stainless steel micron mesh)

FAQS on stainless steel micron mesh

Q: What are the common applications of 75 micron stainless steel mesh?

A: 75 micron stainless steel mesh is widely used in filtration systems for liquids and gases, sieving fine particles in laboratories, and industrial processes requiring precise particle separation. Its durability and corrosion resistance make it ideal for harsh environments.

Q: How does 70 micron stainless steel mesh differ from 60 micron variants?

A: The primary difference lies in aperture size: 70 micron mesh has slightly larger openings than 60 micron, allowing finer filtration with the latter. Both are used in applications like screen printing, sieving, and filtration, depending on required precision.

Q: Is 60 micron stainless steel mesh suitable for high-temperature environments?

A: Yes, 60 micron stainless steel mesh retains structural integrity at high temperatures due to its stainless steel composition. It’s commonly used in aerospace, chemical processing, and food industries where heat resistance is critical.

Q: Can 75 micron stainless steel mesh be customized for specific industrial needs?

A: Absolutely. Manufacturers often tailor wire thickness, weave patterns, and sheet dimensions to suit applications like water treatment, food processing, or pharmaceutical filtration. Customization ensures optimal performance for specialized use cases.

Q: How do I maintain 70 micron stainless steel mesh for longevity?

A: Regular cleaning with mild detergents or ultrasonic methods prevents clogging. Avoid abrasive tools to preserve mesh integrity. Proper storage in dry conditions minimizes corrosion risks, extending its lifespan.