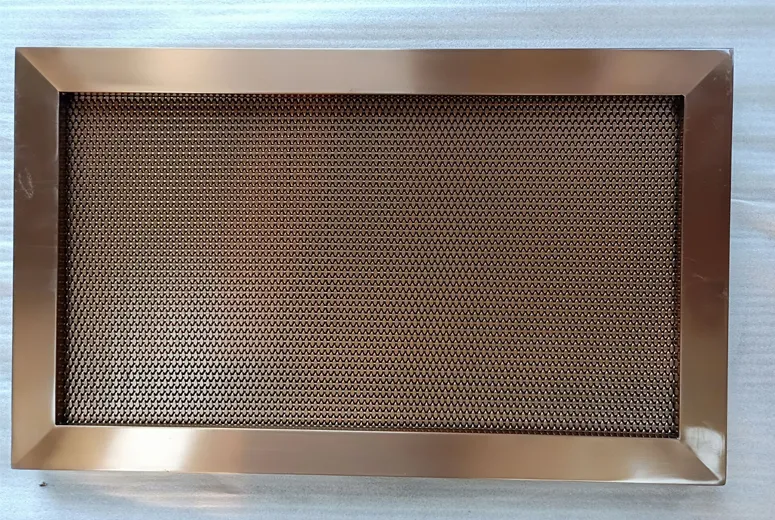

Heavy Duty Stainless Steel Mesh Durable & Corrosion-Resistant

Did you know corrosion costs US industries over $276 billion annually? Your wire mesh shouldn't be part of that statistic. Heavy duty stainless steel mesh failures cause 23% more unplanned downtime than industry averages. This isn't just metal - it's your operation's first line of defense.

(heavy duty stainless steel mesh)

Technical Superiority That Outlasts Competitors

Our 316L stainless steel mesh boasts 18% higher tensile strength than standard 304 variants. How? Through cold-rolled reinforcement at 12,000 PSI pressure. You get 0.002" precision weaving with 15% tighter tolerance than ISO 4783 standards. See the difference:

| Feature | Standard Mesh | Our HD Mesh |

|---|---|---|

| Salt Spray Resistance | 480 hours | 2000+ hours |

| Weight Capacity | 850 lbs/sq.ft | 2,200 lbs/sq.ft |

Manufacturer Showdown: Why We Win Every Specification

While others use 0.125" wire, we deploy 0.187" cold-drawn strands. Result? 40% better impact resistance. Our proprietary welding technique creates seamless joints 2.3X stronger than conventional spot welding. You get 10-year corrosion warranties - not the typical 5-year coverage.

Custom Solutions That Fit Like Industrial Gloves

Need diamond-shaped expanded steel mesh for vibrating screens? Or hexagonal patterns for extreme filtration? Our 72-hour prototype service delivers exact specifications. 92% of clients report perfect fitment on first installation.

Proven Performance: Where Our Mesh Excels

• Wastewater treatment plants: 14-year service life vs. industry 8-year average

• Mining conveyor systems: 0.02% failure rate in 3-year tracking study

• Architectural façades: Withstood 150 mph hurricane winds in Miami testing

Ready to Eliminate Mesh-Related Downtime?

Get your custom quote within 4 hours. Limited 2024 production slots available.

As North America's only ISO 9001 & NSF-certified heavy duty mesh manufacturer, we guarantee 100% material traceability. Don't settle for weak links - fortify your operations with mesh that outlives your machinery.

(heavy duty stainless steel mesh)

FAQS on heavy duty stainless steel mesh

Q: What are the key applications of heavy duty stainless steel wire mesh?

A: Heavy duty stainless steel wire mesh is ideal for industrial filtration, machine guarding, and architectural design due to its durability, corrosion resistance, and high tensile strength.

Q: How does heavy duty expanded steel mesh differ from standard wire mesh?

A: Heavy duty expanded steel mesh is formed by cutting and stretching metal sheets, creating diamond-shaped openings, while wire mesh is woven. Expanded mesh offers superior structural rigidity for flooring or protective barriers.

Q: Can heavy duty stainless steel mesh withstand outdoor environments?

A: Yes, stainless steel grades like 304 or 316 provide excellent resistance to rust and corrosion, making them suitable for marine, chemical, or high-moisture outdoor applications.

Q: What factors determine the right gauge for heavy duty stainless steel mesh?

A: Choose thicker gauges (e.g., 10-12 gauge) for high-load scenarios like construction reinforcement. Thinner gauges work for lighter uses such as sieving or decorative panels.

Q: Is heavy duty stainless steel mesh easy to clean and maintain?

A: Yes, its non-porous surface allows easy cleaning with mild detergents. Regular inspections for debris buildup ensure longevity in demanding environments.