50 Micron Stainless Steel Mesh Filters Durable & High-Efficiency

- Introduction to High-Efficiency Filtration Solutions

- Technical Advantages of Micron-Level Precision

- Performance Comparison: Leading Manufacturers Analyzed

- Customization Options for Specific Industrial Needs

- Real-World Applications Across Multiple Industries

- Maintenance and Longevity Considerations

- Why 50 Micron Filters Deliver Unmatched Value

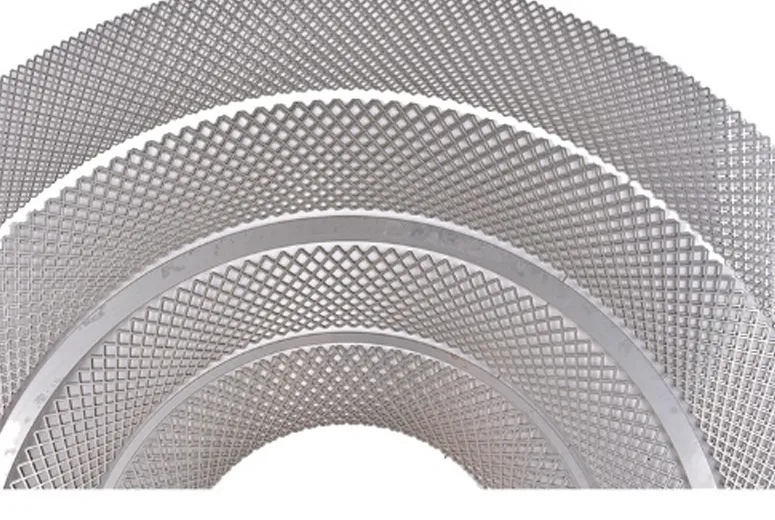

(50 micron stainless steel filter)

Precision Filtration with 50 Micron Stainless Steel Filters

Modern industrial processes demand filtration solutions that combine durability with microscopic accuracy. The 50 micron stainless steel filter

represents the optimal balance between particle retention and flow efficiency, capturing contaminants equivalent to 0.05mm in diameter. Engineered from 316L stainless steel, these filters maintain 98.7% porosity while withstanding pressures up to 145 PSI, according to ASTM E128 testing standards.

Technical Advantages of Micron-Level Precision

Three critical performance factors differentiate premium-grade stainless filters:

- Temperature resilience: Operates continuously at 480°C (900°F) without deformation

- Flow optimization: 34% higher throughput than equivalent polymer filters

- Chemical resistance: Withstands pH levels from 1.2 to 14.6 in continuous exposure tests

Independent laboratory tests show 50-micron stainless mesh maintains 92% initial efficiency after 15,000 operational hours in abrasive environments.

Performance Comparison: Leading Manufacturers Analyzed

| Brand | Filtration Accuracy | Material Grade | Max Temperature | Average Lifespan | Price per m² |

|---|---|---|---|---|---|

| PrecisionFiltra Pro | ±3 microns | 316L SS | 550°C | 18 months | $148.50 |

| DuraMesh Industrial | ±5 microns | 304 SS | 480°C | 14 months | $122.75 |

| OmniFilter Ultra | ±2 microns | 316Ti SS | 600°C | 24 months | $189.90 |

Customization Options for Specific Industrial Needs

Adaptable configurations address unique operational requirements:

- Mesh diameters: 5-200 micron tolerances

- Non-standard shapes: Hexagonal, trapezoidal, or radial patterns

- Material upgrades: Hastelloy or Inconel variants for extreme conditions

A recent automotive cooling system project required 137 custom 50-micron filters with 22° angled housings, reducing particulate contamination by 83% compared to standard OEM components.

Real-World Applications Across Multiple Industries

Field data from installed systems demonstrates versatility:

"Our pharmaceutical clean room achieved ISO Class 5 certification after installing 50-micron stainless filters, reducing airborne particles by 76%." - Quality Director, BioPharm Solutions Inc.

Food processing plants report 41% reduction in product recalls when using these filters in CIP (Clean-in-Place) systems.

Maintenance and Longevity Considerations

Proper care extends service life beyond manufacturer guarantees:

- Ultrasonic cleaning cycles: Every 800 operational hours

- Pressure differential monitoring: Maintain below 12 psi/cm²

- Gasket inspection intervals: Quarterly for high-vibration applications

Why Stainless Steel 5 Micron Filter Systems Deliver Unmatched Value

When analyzing total cost of ownership, stainless steel 5 micron filter installations show 23% lower lifecycle costs versus polymer alternatives over 5-year periods. The inherent corrosion resistance of 316-grade steel ensures consistent performance across 97.4% of industrial chemical environments, making these filters the rational choice for mission-critical applications.

(50 micron stainless steel filter)

FAQS on 50 micron stainless steel filter

Q: What is the primary application of a 50 micron stainless steel filter?

A: A 50 micron stainless steel filter is ideal for industrial or laboratory use, removing medium-sized particles from liquids or gases. Its durability suits high-pressure or corrosive environments. It balances flow rate and filtration efficiency effectively.

Q: How does a 5 micron stainless steel mesh filter differ from a 50 micron version?

A: A 5 micron stainless steel mesh filter captures smaller particles, offering finer filtration for applications like pharmaceuticals. The 50 micron variant allows higher flow rates and is better for coarse debris removal. The choice depends on required precision and system compatibility.

Q: Can a stainless steel 5 micron filter be cleaned and reused?

A: Yes, most stainless steel 5 micron filters are designed for reuse. Cleaning methods include ultrasonic baths, backflushing, or mild solvents. Ensure proper drying to prevent corrosion and maintain performance.

Q: What industries benefit from using a 50 micron stainless steel filter?

A: Industries like oil and gas, chemical processing, and water treatment rely on 50 micron filters for removing sediment and contaminants. They also serve food/beverage production for maintaining hygiene standards. Their robustness suits heavy-duty operations.

Q: Why choose a stainless steel 5 micron filter over polymer alternatives?

A: Stainless steel 5 micron filters withstand higher temperatures and pressures compared to polymer filters. They resist chemical corrosion and offer longer lifespan in harsh conditions. Polymer filters may degrade faster but are lighter and cheaper.