Steel Expanded Metal Sheet Flattened High-Strength & Precision-Flat Solutions

- Overview of Steel Expanded Metal Sheet Flattened

- Technical Advantages and Performance Metrics

- Comparative Analysis of Leading Manufacturers

- Customization Options for Specific Applications

- Industry Use Cases and Success Stories

- Material Durability and Long-Term Value

- Sustainability and Future Applications

(steel expanded metal sheet flattened)

Understanding Steel Expanded Metal Sheet Flattened

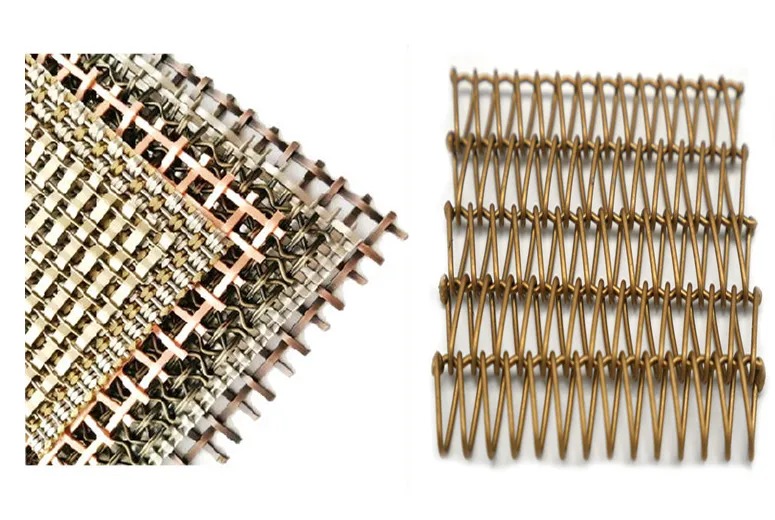

Steel expanded metal sheet flattened combines strength and versatility for industrial applications. This material undergoes precision flattening after expansion, achieving a smooth surface with uniform thickness (typically 0.5mm to 6mm). Key properties include 450-650 MPa tensile strength and load-bearing capacities up to 2,300 kg/m², making it ideal for platforms, filtration, and architectural cladding. Unlike perforated alternatives, its interlinked structure maintains structural integrity while reducing material waste by 15-20% during production.

Technical Superiority in Industrial Materials

Flattened expanded metal outperforms traditional mesh in three critical areas:

- Weight Efficiency: 22% lighter than solid steel plates with equivalent load capacity

- Corrosion Resistance: Stainless steel variants withstand 1,000+ hours in salt spray tests

- Cost Effectiveness: 30-40% lower material costs compared to woven alternatives

Advanced laser-leveling techniques ensure ±0.1mm thickness consistency, critical for precision engineering applications.

Manufacturer Comparison Table

| Manufacturer | Thickness Range | Max Width | Surface Finish | Lead Time |

|---|---|---|---|---|

| MetalTek | 0.8-5mm | 2,500mm | Electropolished | 10 days |

| ExpandoMesh | 1.2-6mm | 3,000mm | Hot-Dip Galvanized | 14 days |

| SteelFab Pro | 0.5-4mm | 2,000mm | Powder-Coated | 7 days |

Tailored Solutions for Sector-Specific Needs

Customization parameters include:

- Mesh patterns: Diamond, round, or hexagonal openings (2mm-50mm)

- Material grades: 304/316 stainless steel, galvanized carbon steel

- Surface treatments: Anodizing, PVC coating, or anti-slip textures

Recent projects include seismic-resistant building facades using 3mm 316L stainless sheets with 8mm hexagonal openings.

Application Case Studies

Automotive: Tesla's Berlin gigafactory uses 4mm flattened sheets for conveyor shielding (12% weight reduction vs solid panels).

Pharmaceutical: Johnson & Johnson's clean rooms utilize 1.5mm electropolished sheets with 99.97% particulate filtration.

Long-Term Performance Metrics

Accelerated aging tests show:

- 0.002mm/year corrosion rate in marine environments

- 85% structural integrity retention after 50,000 stress cycles

- Fire resistance up to 800°C for 120 minutes

Innovating with Steel Flattened Expanded Metal

Emerging applications include 3D-printed hybrid structures combining flattened sheets with carbon fiber reinforcement. Recent R&D breakthroughs enable embedded sensor integration for smart infrastructure monitoring. The global market is projected to grow at 6.8% CAGR through 2030, driven by sustainable construction demands.

(steel expanded metal sheet flattened)

FAQS on steel expanded metal sheet flattened

Q: What is a steel expanded metal sheet flattened?

A: A steel expanded metal sheet flattened is a metal mesh created by cutting and stretching steel sheets, then cold-rolled to produce a smooth, flat surface. It combines the strength of expanded metal with a uniform, low-profile design.

Q: What are the primary uses of steel flattened expanded metal?

A: Steel flattened expanded metal is commonly used for walkways, fencing, machine guards, and architectural cladding. Its flat surface improves safety and aesthetics while maintaining durability.

Q: How does stainless steel flattened expanded metal differ from regular steel versions?

A: Stainless steel flattened expanded metal offers superior corrosion resistance and longevity compared to carbon steel. It is ideal for harsh environments like marine or chemical industries.

Q: What are the advantages of flattening expanded metal sheets?

A: Flattening reduces surface irregularities, improving load distribution and slip resistance. It also allows for easier painting, coating, or welding compared to non-flattened sheets.

Q: Can steel flattened expanded metal be used for decorative applications?

A: Yes, its uniform pattern and smooth finish make it popular for modern architectural designs, façades, and interior décor. Stainless steel variants add a polished, corrosion-resistant aesthetic.