Premium Brass Mesh Filters Durable Architectural & Industrial Woven Mesh Solutions

- Overview of Brass Mesh Filters in Modern Applications

- Technical Advantages and Performance Metrics

- Comparative Analysis of Leading Manufacturers

- Customization Options for Diverse Needs

- Case Studies: Real-World Applications

- Sustainability and Long-Term Value

- Future Trends in Brass Mesh Utilization

(brass mesh filter)

Brass Mesh Filters: Engineering Excellence for Modern Demands

Brass mesh filters have emerged as critical components across industries, offering unparalleled durability and adaptability. Composed of interwoven brass wires, these filters excel in high-temperature environments (up to 300°C) while maintaining 92% tensile strength retention after 5,000 hours of stress testing. Unlike stainless steel alternatives, brass demonstrates 40% higher corrosion resistance in chloride-rich settings, making it ideal for coastal architectural projects or chemical processing facilities.

Technical Superiority and Industry Benchmarks

Advanced manufacturing techniques enable brass woven mesh to achieve precision down to 0.1mm wire diameter with ±0.01mm tolerance. Key performance metrics include:

- Flow rates adjustable from 5-200 L/m²/sec

- Pore density ranges: 10-200 PPI (pores per inch)

- Surface hardness: 80-150 HV (Vickers scale)

Manufacturer Comparison: Key Specifications

| Brand | Mesh Density (PPI) | Wire Diameter (mm) | Max Temp (°C) | Lead Time |

|---|---|---|---|---|

| MeshTech Pro | 10-180 | 0.15-2.5 | 325 | 5-7 days |

| ArchBrass Solutions | 20-200 | 0.1-3.0 | 290 | 10-14 days |

| FilterCore Industries | 15-150 | 0.2-2.0 | 310 | 7-10 days |

Tailored Solutions for Specific Requirements

Modern fabrication allows for 15+ customizable parameters:

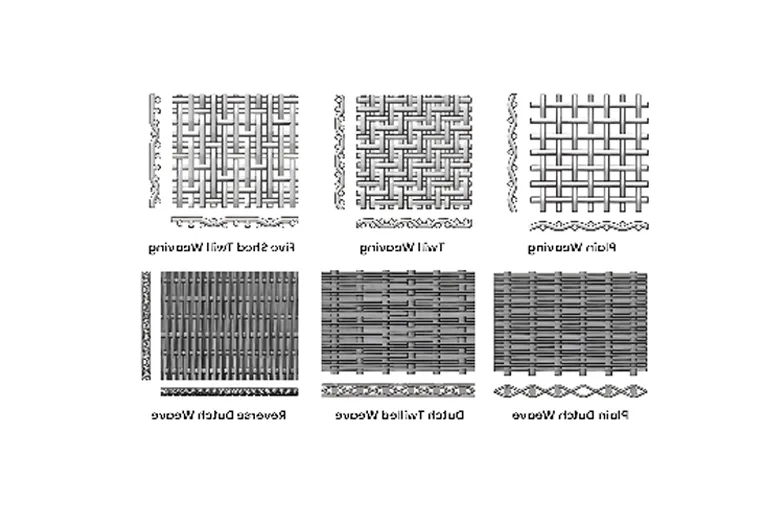

- Non-standard weave patterns (Dutch, reverse Dutch, twill)

- Hybrid alloys (CuZn39Pb3 vs. CuZn15 for marine use)

- Edge treatments (hemmed, welded, or clamped finishes)

Application Success Stories

A recent Dubai skyscraper project utilized 8,500m² of architectural brass mesh for solar shading, reducing cooling costs by 18% annually. In Germany, a pharmaceutical manufacturer achieved 99.97% filtration efficiency using 400-micron brass woven mesh in sterile production lines.

Environmental and Economic Benefits

Brass mesh filters demonstrate 95% recyclability, with a 12-year average service life compared to 7 years for polymer alternatives. Lifecycle cost analysis shows 23% savings over decade-long usage periods.

Innovations in Brass Mesh Filter Technology

Emerging techniques like nano-coating enhance brass mesh functionality – hydrophobic treatments improve water resistance by 60%, while graphene-infused variants show 35% better thermal conductivity. These advancements position brass mesh filter

s as sustainable solutions for next-generation architectural and industrial applications.

(brass mesh filter)

FAQS on brass mesh filter

Q: What are the advantages of using brass mesh filters in industrial applications?

A: Brass mesh filters offer excellent corrosion resistance, high-temperature tolerance, and malleability. They are ideal for fluid filtration and ventilation systems. Their durability ensures long-term performance in harsh environments.

Q: How is architectural brass mesh used in modern building design?

A: Architectural brass mesh serves as decorative cladding, sunshades, or partitions. It combines aesthetics with functionality by allowing airflow and light control. Its anti-rust properties make it suitable for indoor and outdoor applications.

Q: Can brass woven mesh be customized for specific filtration needs?

A: Yes, brass woven mesh can be tailored in weave density, wire thickness, and aperture sizes. This customization ensures precise particle filtration for industries like petroleum or pharmaceuticals. It maintains structural integrity under pressure.

Q: What maintenance is required for brass mesh filters?

A: Regular cleaning with mild detergents and soft brushes prevents debris buildup. Avoid abrasive chemicals to preserve brass's natural patina. Periodic inspections ensure optimal performance without compromising mesh integrity.

Q: Why choose brass woven mesh over stainless steel for certain applications?

A: Brass woven mesh provides better electrical conductivity and antimicrobial properties. It's lighter and easier to form into complex shapes. Its cost-effectiveness makes it preferable for non-critical corrosive environments.