-

5 Poin Penjualan

High-quality material: Made of high-quality stainless steel, it has excellent corrosion resistance. Whether it is facing highly corrosive chemical liquids such as acids and alkalis, or a humid working environment, it can be used stably for a long time, is not easy to rust and damage, and has a service life far exceeding that of ordinary filter mesh cylinders, saving you replacement costs.

High filtration accuracy: Strictly control the aperture size of the mesh cylinder, the accuracy can reach the micron level, can accurately intercept various tiny particles and impurities, and has a good filtration effect on particles of 0.1 microns or even smaller, ensuring that the filtered liquid or gas reaches a high purity standard and meets your strict requirements for filtration quality.

Reasonable structural design: The unique multi-layer structure design increases the filtration area, improves the dirt holding capacity, and greatly improves the filtration efficiency. At the same time, this structure also enhances the pressure resistance of the filter mesh cylinder. Even if it works under a higher pressure environment, it will not deform, ensuring the continuous and stable operation of the filtration work.

Strong versatility: It has a variety of specifications and sizes, and can be customized according to different equipment and filtration process requirements. It can perfectly adapt to various filtration equipment and is widely used in many industries such as food and beverage, chemical, pharmaceutical, petroleum, water treatment, etc., to meet the filtration operation requirements in different fields.

Easy to clean and maintain: The surface of stainless steel is smooth, impurities are not easy to adhere, and cleaning is simple and convenient. A variety of cleaning methods can be used, such as backwashing, ultrasonic cleaning, etc., which can quickly and effectively remove dirt on the filter mesh cylinder, restore its filtration performance, reduce downtime, and improve production efficiency.

-

-

Karakteristik Parameter Produk

Nama Produk

Stainless steel filter mesh cylinder

Tempat produksi

Cina Hebei

Jenis

Produk yang disesuaikan

Tekstur kayu

304 316 316L Baja tahan karat

Keahlian

Proses penenunan, pelubangan, pengetsaan dan pemotongan laser

Warna

Warna baja tahan karat

Ukuran

Disesuaikan

Gaya

Kesederhanaan

Skenario aplikasi

Dapur, pertanian, laboratorium, industri kimia, dll.

-

Pengetahuan Produk Sains Populer

Satu Paragraf: apa produk ini?

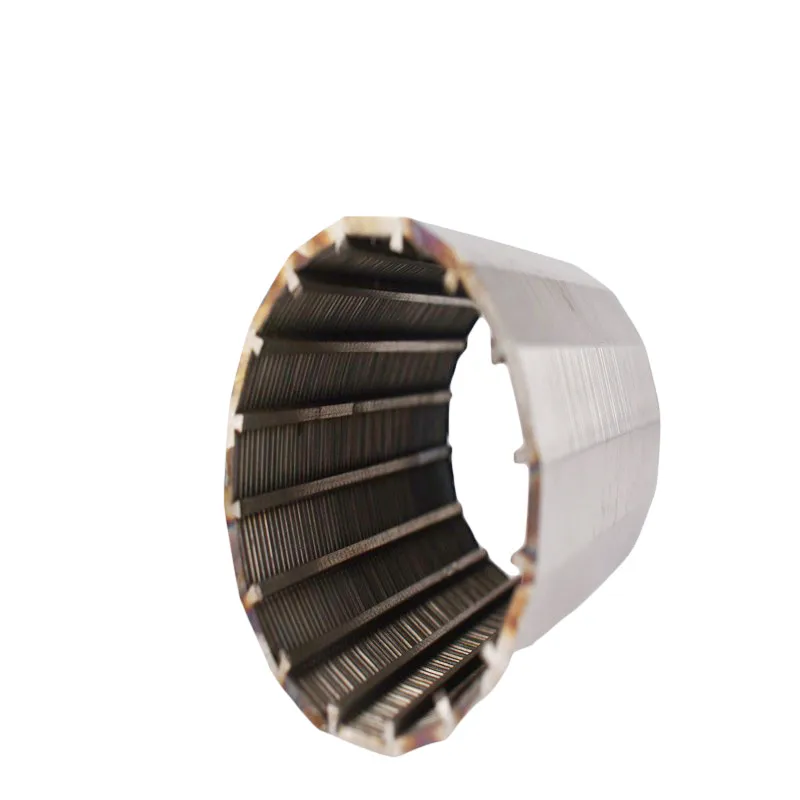

Stainless steel filter mesh cylinder is a product used for filtration. It is usually made of stainless steel, with good corrosion resistance, high strength and stability. Its structure includes the filter mesh cylinder body or the interfaces at both ends. The filter mesh cylinder body is composed of filter elements such as stainless steel filter screen or porous plate. This product can effectively filter impurities, particles, etc. in liquid or gas, and is widely used in chemical, petroleum, pharmaceutical, food and beverage, water treatment and other industries. It can be customized according to different filtration accuracy, flow and pressure requirements to meet various filtration needs.

Dua Paragraf:Aplikasi produk ini?

Stainless steel filter mesh cylinder have been widely used in many fields due to their excellent corrosion resistance and long service life. With the advancement of technology, more and more industries have begun to recognize the advantages of stainless steel filter elements and have become an indispensable part of modern filtration systems.

Industrial production field

In the chemical industry, various chemical raw materials in the reactor can be filtered through stainless steel filter mesh cylinder to accurately remove impurities, ensure the smooth progress of chemical reactions, ensure stable product quality, and ensure that each batch of chemical products meets high standards. During petroleum refining, stainless steel filter mesh cylinder can effectively filter impurities in crude oil, prevent equipment wear, extend the service life of refining equipment, and help efficiently refine high-quality oil products.

Environmental water treatment scene

In sewage treatment plants, a large amount of sewage flows through stainless steel filter mesh cylinder. Like loyal guards, it intercepts solid particles and suspended matter in sewage, laying a solid foundation for subsequent purification treatment. In industrial circulating water systems, stainless steel filter mesh cylinder can continuously filter impurities in water, ensure the cleanliness of circulating water, achieve efficient recycling of water resources, and reduce corporate production costs.

Food and pharmaceutical industry

In the food production process, whether it is the filtration of raw materials before beverage filling or the removal of impurities in edible oil processing, stainless steel filter mesh cylinder can protect the safety and purity of food with their sanitary materials and precise filtering capabilities. In the pharmaceutical field, from the preparation of liquid medicine to the canning of finished products, stainless steel filter mesh cylinder are involved in the whole process to ensure that the medicine is free of impurity contamination and ensure the safety of patients' medication.

-

Gambar Produk Dan Aplikasi

Material details:

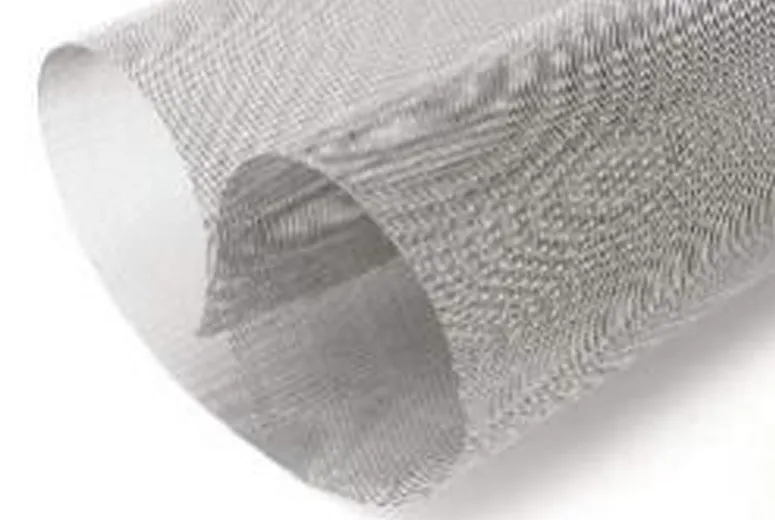

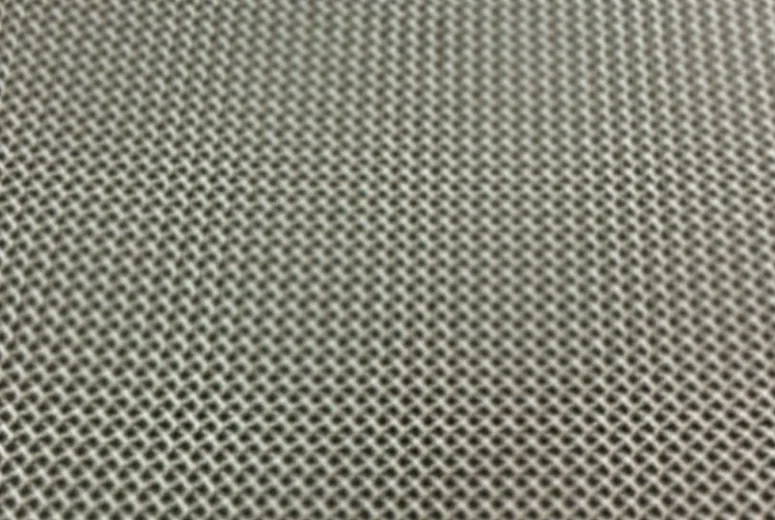

Stainless steel selection: Common ones include SUS304, which has good corrosion resistance and comprehensive performance and is suitable for most general environments; SUS316L performs better in highly corrosive environments such as chlorine.

Wire mesh types: mainly woven mesh, perforated mesh, welded mesh, etc. Woven mesh has high filtration accuracy and can intercept fine particles; perforated mesh has regular holes and high strength; welded mesh has good stability and corrosion resistance.

Production process details:

Cutting: Use professional cutting equipment to ensure accurate size and neat edges to avoid size deviation and burrs that affect installation and use.

Welding: According to different materials and usage requirements, choose appropriate welding methods, such as spot welding, roll welding, arc welding, etc., to ensure that the weld is uniform and firm, without false welding or leaking welding.

Surface treatment: Common ones include electrolytic polishing and plastic spraying. Electrolytic polishing can make the surface as bright as a mirror, improve corrosion resistance and aesthetics; plastic spraying can form a protective film on the surface to enhance rust and corrosion resistance.

Structural design details:

Shape and size: various shapes, including round, square, conical, etc. In terms of size, the diameter is generally 4mm-2000mm, and the height is 4mm-6000mm, which can be customized according to actual needs.

Filtering accuracy: By controlling the mesh size to achieve different filtering accuracies, generally 2-200μm, to meet various filtering needs.

Interface form: There are threaded interfaces, standard interfaces, quick interface links, flange connections, pull rod links, etc., which are convenient for connection with different equipment.

Performance details:

Filtration efficiency: It has good filtration performance for 1-500um particles and liquids, with a large flow rate per unit area, which can effectively intercept impurities and ensure the filtration effect.

Corrosion resistance: It can work stably in corrosive media such as acids and alkalis, is not easily corroded and damaged, and is suitable for a variety of harsh environments.

Pressure resistance: It has high strength and toughness, can withstand a certain amount of pressure, and is not easy to deform or break under high pressure.

Some Products Show:

Skenario Aplikasi

Stainless steel filter cylinder is a highly efficient filtering equipment, which is widely used in many fields:

Petrochemical field

In the process of petroleum refining and chemical production, it is used to filter various oil products, chemical raw materials and intermediates, remove solid impurities and particles, etc., to ensure product quality and normal operation of production equipment.

Bidang perlindungan lingkungan

In environmental protection projects such as waste gas treatment and sewage treatment, it is used to filter dust in waste gas and suspended solids in sewage treatment, which helps to improve the treatment efficiency of environmental protection equipment and reduce pollutant emissions.

Biomedicine field

In the process of drug production, it is used to filter liquid medicine, plasma, etc., remove microorganisms, impurities, etc., to ensure the purity and safety of drugs.

Water treatment field

In water plants, sewage treatment plants and industrial circulating water treatment, it is used to filter impurities such as silt, rust, colloids in water, improve water quality and meet different water needs.

Food and beverage field

In the production process of food and beverage, it is used to filter impurities, pulp fibers, etc. in juice, beer, beverages, etc., to improve the taste and quality of the product.

Mechanical manufacturing field

In hydraulic systems, lubrication systems, etc., it is used to filter metal chips, impurities, etc. in the oil to ensure the normal operation of mechanical equipment and extend the service life of the equipment.

-

-

Berapa waktu tunggu rata-rata?

Permintaan Penawaran

Jika Anda tertarik dengan produk kami, Anda dapat memilih untuk meninggalkan informasi Anda di sini, dan kami akan segera menghubungi Anda.