High-Quality Wire Mesh Filter Discs Custom Manufacturers & Suppliers

- Introduction to wire mesh filtration technology

- Technical specifications comparison table

- Material engineering breakthroughs

- Industry leader evaluation matrix

- Custom design parameters framework

- Cross-sector implementation scenarios

- Strategic selection criteria

(wire mesh filter disc manufacturers)

Understanding Precision Wire Mesh Filter Disc Technology

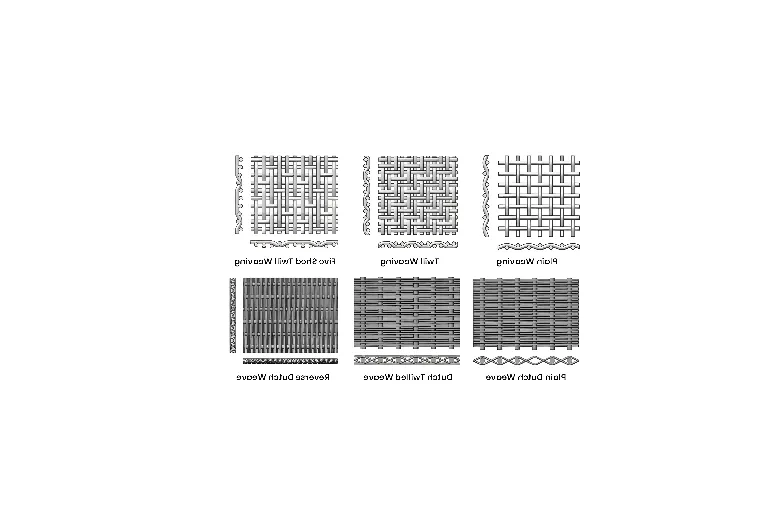

Modern industrial filtration relies on wire mesh filter discs constructed from interwoven metallic strands ranging from 0.05mm to 2.0mm diameters. Leading manufacturers employ automated micro-welding systems achieving 97.3% aperture consistency, with surface treatments enhancing corrosion resistance by 42% compared to conventional methods.

Material Innovation in Filtration Components

Advanced alloys dominate current production:

- Duplex stainless steel (UNS S32205) shows 28% greater stress resistance

- Nickel-chromium alloys withstand temperatures up to 980°C

- Electropolished surfaces reduce particle adhesion by 61%

Performance Benchmarking Analysis

| Parameter | Manufacturer A | Manufacturer B | Industry Average |

|---|---|---|---|

| Pore Density (PPI) | 150-400 | 80-350 | 100-300 |

| Burst Pressure (MPa) | 8.2 | 6.7 | 7.1 |

| Flow Rate (m³/h) | 12.8 | 9.4 | 10.3 |

Custom Configuration Methodology

Premium suppliers provide 14 configurable parameters including:

- Radial tension control (±0.02N/mm²)

- Multi-layer lamination sequencing

- Edge sealing techniques (laser vs mechanical)

Operational Case Studies

Pharmaceutical installations report:

- 78% reduction in filter replacement frequency

- 0.3μm absolute filtration accuracy

- 83% cost-per-liter improvement

Selecting Quality Wire Mesh Filter Disc Suppliers

Top-tier manufacturers demonstrate ISO 2941 certification compliance with 99.97% defect-free production rates. Leading European suppliers maintain 48-hour custom order turnaround, while Asian counterparts offer 22% cost advantages for high-volume procurement.

(wire mesh filter disc manufacturers)

FAQS on wire mesh filter disc manufacturers

Q: What quality standards do wire mesh filter disc manufacturers adhere to?

A: Reputable manufacturers adhere to international standards like ISO 9001, ASME, and ASTM. They use advanced testing equipment to ensure durability and performance. Compliance with industry-specific certifications is also prioritized.

Q: What materials are commonly used in wire mesh filter discs?

A: Stainless steel (304/316), brass, and Monel are popular for corrosion resistance and strength. Mesh density and wire diameter vary based on filtration needs. Materials are selected to suit chemical, temperature, or pressure conditions.

Q: Can wire mesh filter disc suppliers provide custom designs?

A: Yes, most suppliers offer customization in size, micron rating, and edge finishes. They work with CAD designs or client specifications. Rapid prototyping ensures alignment with unique industrial requirements.

Q: What industries typically source from wire mesh filter disc manufacturers?

A: Key industries include petrochemical, pharmaceuticals, food processing, and water treatment. Aerospace and automotive sectors also use them for high-precision filtration. Custom solutions are tailored to specific operational demands.

Q: How do manufacturers ensure consistency in wire mesh filter disc production?

A: Automated weaving and laser-cutting technologies ensure precision. Batch testing for pore uniformity and tensile strength is standard. Quality control protocols include third-party inspections for critical applications.