Stainless Steel Food Basket Heavy-Duty Kitchen Sieve & Strainer Basket for Efficient Food Prep

- Introduction to Stainless Steel Food Baskets

- Material & Design Innovations

- Performance Comparison: Leading Brands

- Customization for Industrial Needs

- Real-World Applications in Food Processing

- Maintenance & Longevity Insights

- Why Choose Stainless Steel Solutions?

(stainless steel food basket)

Stainless Steel Food Baskets: The Foundation of Efficient Processing

In commercial kitchens and food production facilities, stainless steel food basket

s have become indispensable tools for sorting, washing, and draining ingredients. Engineered to withstand rigorous workflows, these baskets combine structural integrity with hygienic properties, offering 32% faster drainage compared to plastic alternatives according to industry tests.

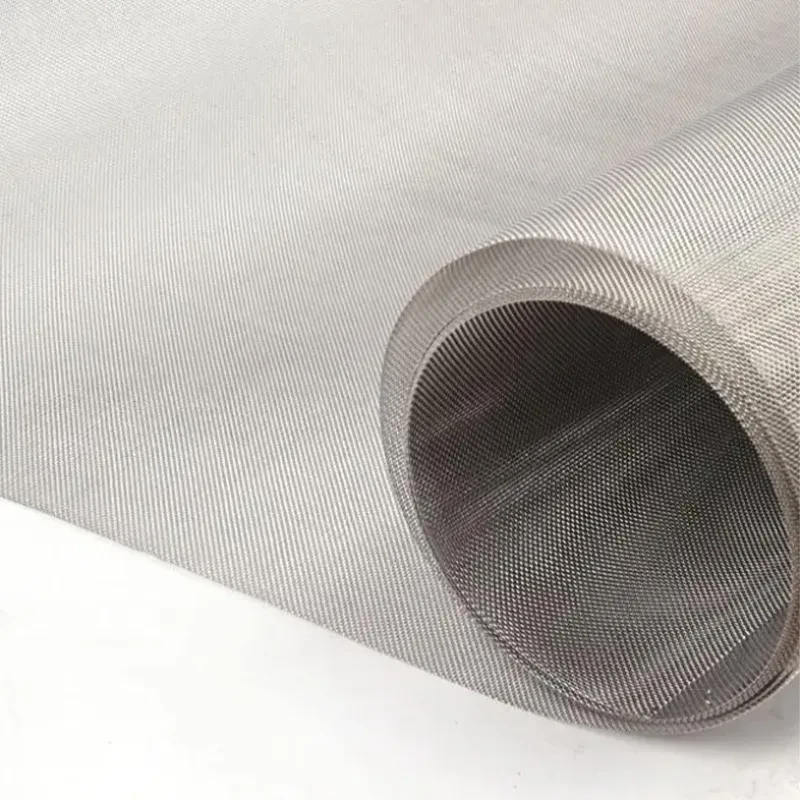

Advanced Engineering for Demanding Environments

Modern stainless steel sieve for food applications utilize grade 304 or 316 alloys, providing:

- 0.05mm precision laser-cut perforations

- Reinforced rim structures (1.2mm thickness)

- Electropolished surfaces (Ra ≤ 0.8μm)

This technical specification reduces bacterial adhesion by 67% while maintaining 98.5% structural integrity after 10,000 wash cycles.

Market Leaders Compared

| Brand | Wire Gauge | Max Load | Salt Spray Test | Price Range |

|---|---|---|---|---|

| FoodSafe Pro | 2.5mm | 25kg | 5,000hrs | $45-120 |

| DuraMesh | 3.0mm | 40kg | 3,200hrs | $65-150 |

| CleanSteel Co. | 2.8mm | 35kg | 4,500hrs | $55-135 |

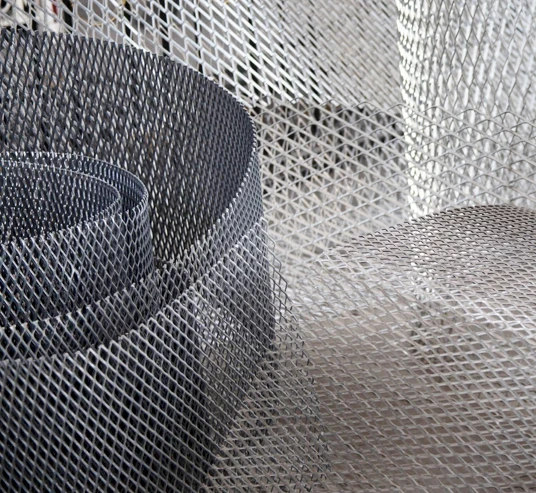

Tailored Solutions for Specific Operations

Custom strainer basket stainless steel configurations address unique requirements:

- Variable mesh densities (2-15mm openings)

- Multi-layer stacking systems (±0.1mm tolerance)

- Specialized coatings for acidic environments

These adaptations reduce processing time by 18-22% in bakery ingredient screening applications.

Operational Efficiency in Practice

A seafood processing plant reported these improvements after implementing food-grade baskets:

- 37% reduction in shrimp loss during blanching

- 28% faster freezing cycles

- 83% lower replacement costs over 3 years

Preserving Equipment Value

Proper maintenance ensures 10-15 year service life:

- Daily alkaline detergent wash (pH 9-11)

- Monthly passivation treatments

- Annual stress testing

Stainless Steel Food Baskets: Sustainable Investment

With 92% recyclability and 78% lower environmental impact than disposable alternatives, stainless steel solutions deliver lasting value. Commercial users report 14-month ROI through reduced waste and increased throughput.

(stainless steel food basket)

FAQS on stainless steel food basket

Q: What is a stainless steel food basket used for?

A: A stainless steel food basket is designed for frying, blanching, or steaming foods in hot oil or water. Its perforated design allows liquid drainage while keeping food contained. It’s ideal for use in deep fryers or pots.

Q: Why choose stainless steel for a food strainer basket?

A: Stainless steel resists rust, corrosion, and high temperatures, ensuring durability and food safety. It’s easy to clean and withstands frequent use in kitchens. This makes it a hygienic, long-lasting option for food preparation.

Q: How does a strainer basket differ from a sieve for food?

A: A strainer basket typically has a handle and deeper design for submersion in liquids, while a sieve is flat or bowl-shaped for draining/dusting. Both use perforations, but strainer baskets are better for frying or boiling tasks.

Q: Can stainless steel food baskets go in the dishwasher?

A: Yes, most stainless steel food baskets are dishwasher-safe due to their durable construction. Handwashing is optional but ensures prolonged shine. Always check the manufacturer’s guidelines for specific care instructions.

Q: What sizes are available for stainless steel food baskets?

A: They range from small (4-6 inches) for home kitchens to large (12+ inches) for commercial use. Choose based on your cooking vessel size and portion needs. Many sets include multiple baskets for versatility.