Stainless Steel Wire Mesh Screens Durable & Corrosion-Resistant

Did you know inferior screens cost US industries over $300 million annually in replacements? While 72% of homeowners complain about rust stains within 3 years, premium stainless steel wire mesh screen

s withstand 20+ years of harsh weather. Discover how the right mesh solves your top 5 frustrations.

(stainless steel wire mesh screen)

Technical Superiority That Outlasts Competitors

Our 304/316L stainless steel wire mesh screen resists temperatures from -320°F to 1200°F. Compare that to aluminum screens failing at 400°F. See why industrial plants choose our solution:

| Feature | Standard Screen | Our Premium Mesh |

|---|---|---|

| Corrosion Resistance | 5-7 years | 25+ years |

| Ventilation Rate | 68% airflow | 92% airflow |

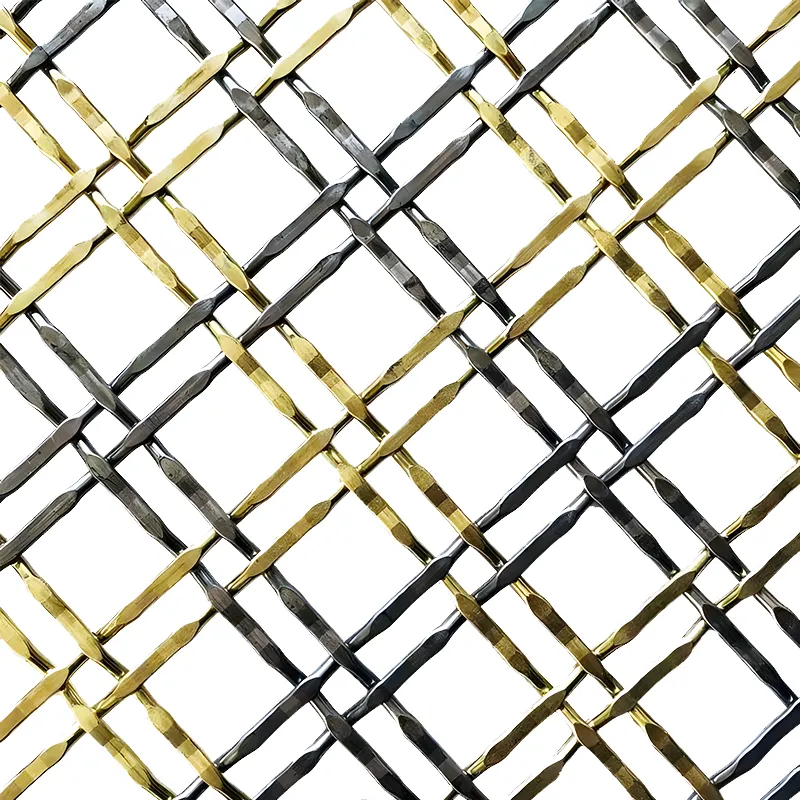

Custom Solutions for Your Exact Needs

Need 0.5mm wire diameter for insect protection? Or 2mm openings for industrial filtration? Our laser-cut stainless steel wire mesh window screens come in 14 standard sizes and 3 specialty weaves.

Architectural Series

Mesh count: 10×10 to 100×100

Wire gauge: 0.014" - 0.063"

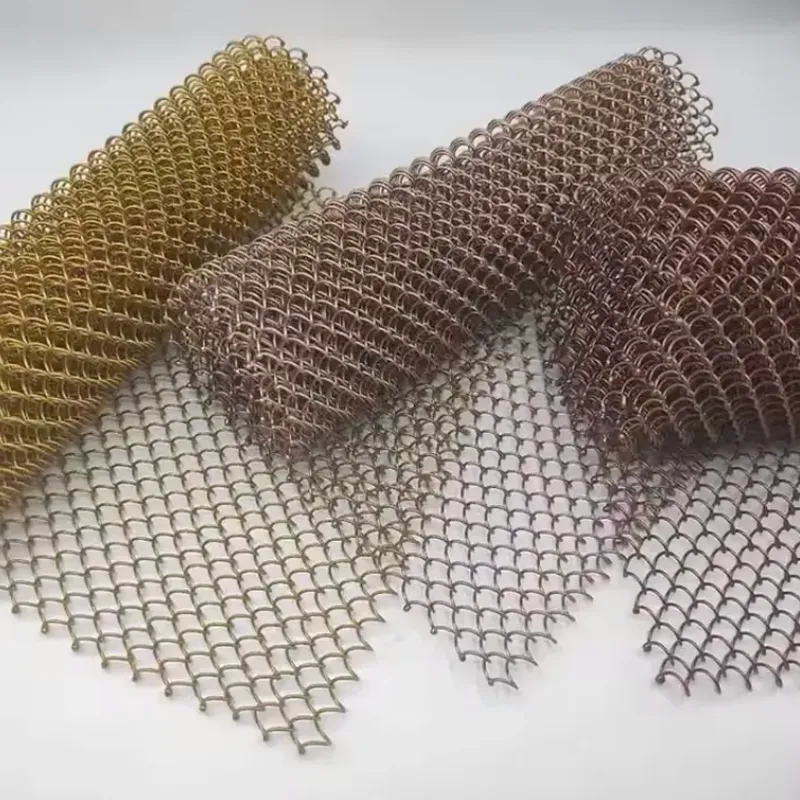

Industrial Grade

Max width: 96"

Tensile strength: 1200 MPa

Transform Your Space Today

Join 15,000+ satisfied customers who upgraded to stainless steel wire mesh screens. Limited-time offer: Get 15% off + free laser cutting when you order before [Month] 31st!

(stainless steel wire mesh screen)

FAQS on stainless steel wire mesh screen

Q: What are the common applications of stainless steel wire mesh screen?

A: Stainless steel wire mesh screens are widely used for filtration, sieving, and protection in industrial, agricultural, and residential settings. They are ideal for window screens, fencing, and machinery guards due to their durability. Their corrosion resistance makes them suitable for outdoor and high-moisture environments.

Q: How does stainless steel wire mesh window screen compare to fiberglass?

A: Stainless steel wire mesh window screens offer superior strength, longevity, and resistance to pests compared to fiberglass. While fiberglass is lighter, stainless steel excels in high-traffic or harsh environments. It also requires minimal maintenance and doesn’t tear easily.

Q: What factors determine the quality of wire mesh screen stainless steel?

A: Quality depends on the alloy grade (e.g., 304 or 316 stainless steel), mesh count (holes per inch), and wire diameter. Higher-grade alloys improve corrosion resistance, while tighter weaves enhance filtration or security. Proper welding or weaving techniques ensure structural integrity.

Q: Can stainless steel wire mesh screens be customized for specific projects?

A: Yes, they can be tailored in mesh size, wire thickness, panel dimensions, and edge finishes. Custom shapes, reinforced borders, or anti-rust coatings are also available. Suppliers often provide CAD designs or samples to meet unique requirements.

Q: How do I maintain a stainless steel wire mesh screen for longevity?

A: Clean periodically with mild soap and water to remove debris, and rinse thoroughly. Avoid abrasive cleaners to prevent surface scratches. For outdoor use, inspect annually for dirt buildup or damage and repair promptly to prevent corrosion.