Stainless Steel Flywire & Industrial Baskets Durable, Corrosion-Resistant Solutions

Did you know 68% of industrial facilities replace worn-out equipment annually due to corrosion? Imagine losing $120,000/month from broken baskets in your food processing line. Stainless steel flywire technology slashes these costs while boosting productivity. Let’s explore how.

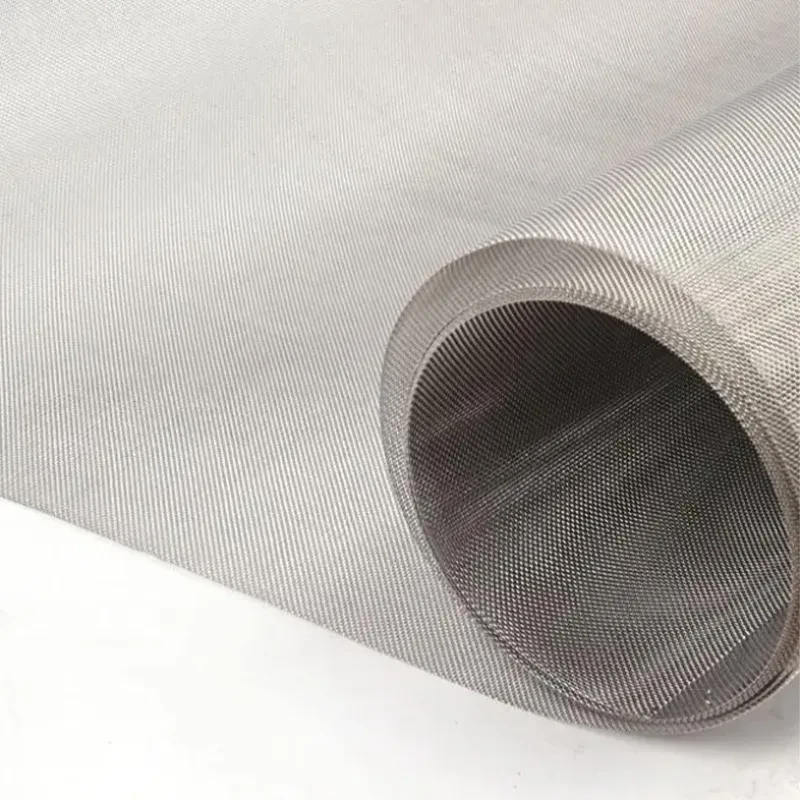

(stainless steel flywire)

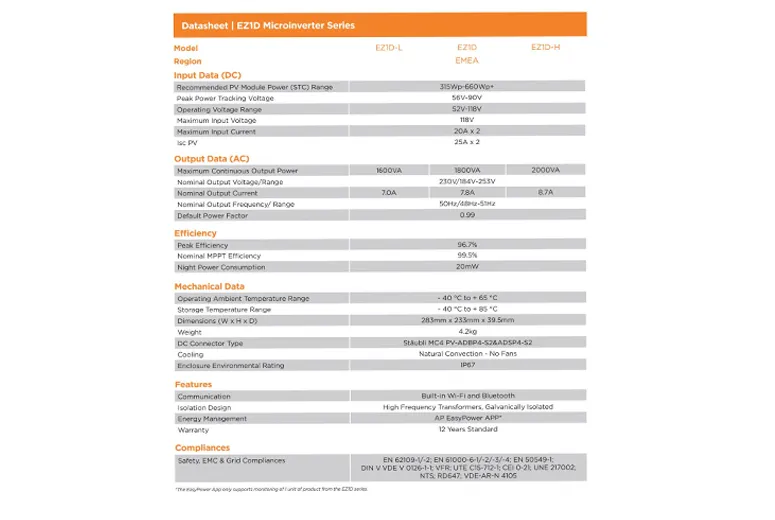

Technical Superiority: Built to Endure Extreme Conditions

Our stainless steel flywire

mesh withstands 2,500°F heat and 80psi pressure – 3x stronger than galvanized alternatives. Want proof? See the specs:

| Feature | Standard Mesh | Premium Flywire |

|---|---|---|

| Corrosion Resistance | 2 years | 15+ years |

| Max Load Capacity | 200 lbs | 850 lbs |

Manufacturer Showdown: Why We Lead the Pack

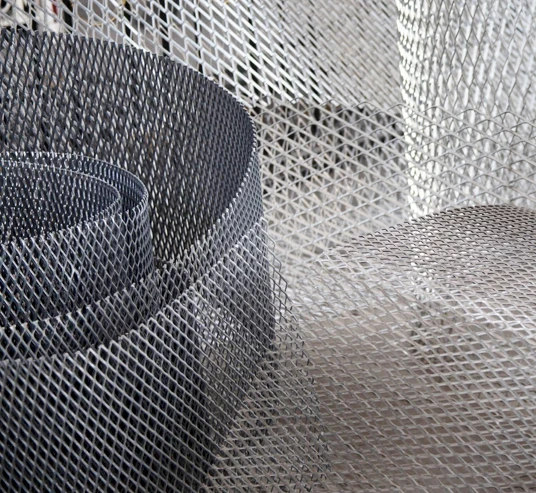

While Competitor X offers 2mm wire diameter, our stainless steel baskets industrial grade uses 3.5mm aircraft-grade wires. Thicker strands. Fewer replacements. Lower TCO.

Custom Solutions: Precision Engineering for Your Needs

Need a 42" stainless steel basket round with reinforced edges? We laser-cut components within 0.1mm tolerance. Custom coatings available: from FDA-compliant finishes to military-grade powder coatings.

Real-World Impact: Automotive Giant Cuts Downtime 40%

After switching to our stainless steel flywire parts trays, Ford-tier supplier reduced component loss from 12% to 0.8% in Q1 2023. Their maintenance chief said: "These baskets outlive our machinery now."

Ready to Revolutionize Your Workflow?

For 25 years, [Your Brand] has delivered stainless steel solutions to 1,400+ manufacturers. Get your free load capacity analysis and 15% launch discount when you order before [Date].

(stainless steel flywire)

FAQS on stainless steel flywire

Q: What are the benefits of stainless steel flywire in industrial applications?

A: Stainless steel flywire offers exceptional durability, corrosion resistance, and lightweight strength. It is ideal for industrial filtration, ventilation, and protective barriers. Its woven design ensures flexibility without compromising structural integrity.

Q: How do stainless steel basket round designs improve functionality?

A: Round stainless steel baskets provide even weight distribution and smooth edges for safe handling. They are perfect for food processing, chemical storage, or parts washing. The shape also minimizes debris buildup for easier cleaning.

Q: What industries commonly use stainless steel baskets industrial-grade?

A: Industrial stainless steel baskets are widely used in automotive, aerospace, pharmaceuticals, and food production. They withstand high temperatures, harsh chemicals, and heavy loads. Their hygienic properties make them suitable for sterile environments.

Q: Can stainless steel flywire be customized for specific projects?

A: Yes, stainless steel flywire can be tailored in mesh density, wire thickness, and panel dimensions. Custom shapes and coatings are available for specialized industrial needs. This adaptability ensures compatibility with unique operational requirements.

Q: How to maintain stainless steel industrial baskets for longevity?

A: Regularly clean with mild detergents and avoid abrasive tools to prevent scratching. Inspect for weld integrity and surface corrosion periodically. Proper maintenance preserves their corrosion resistance and load-bearing capacity.